Co-extrusion method of fabricating electrode structures in honeycomb substrates and ultracapacitor formed thereby

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

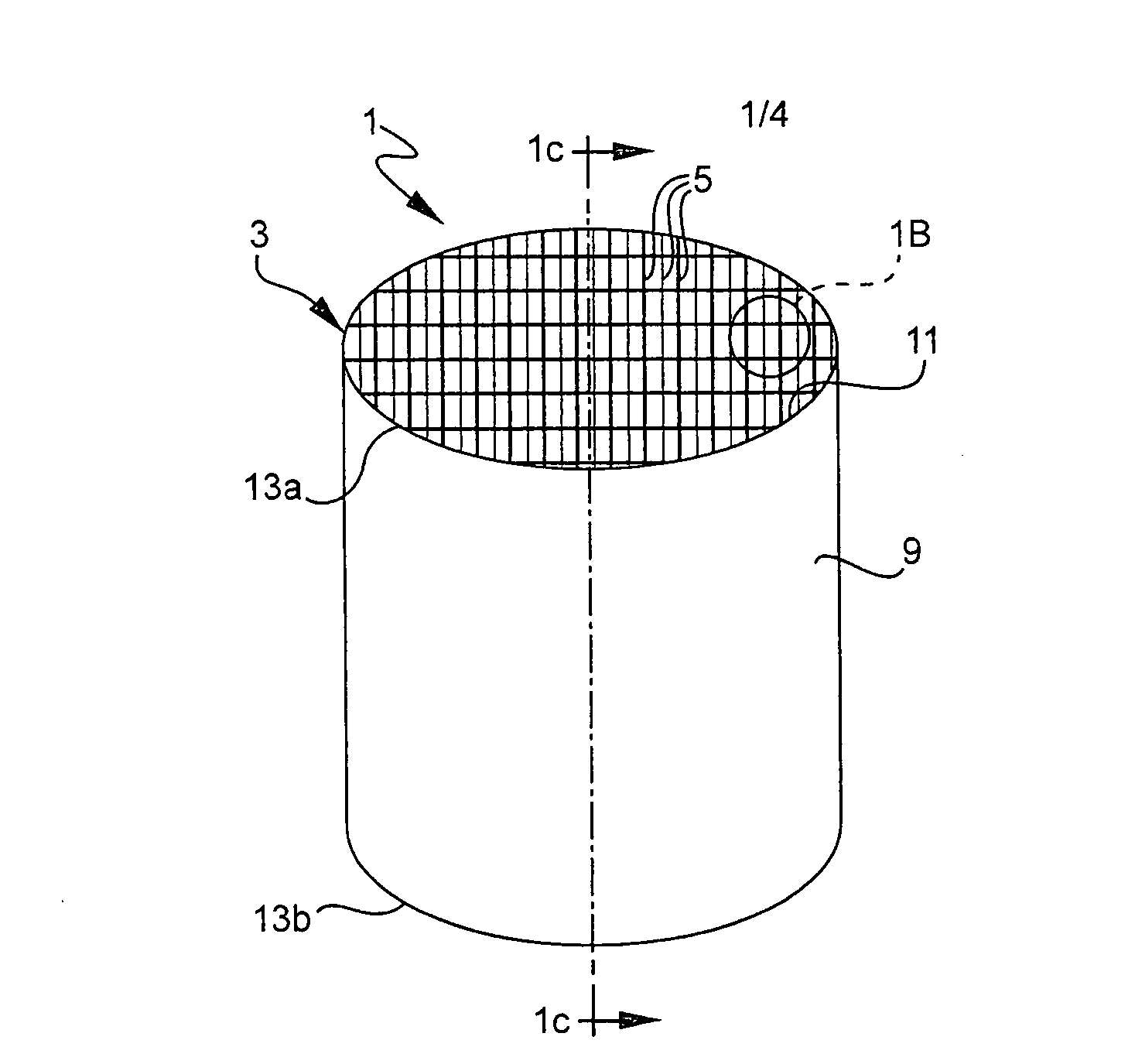

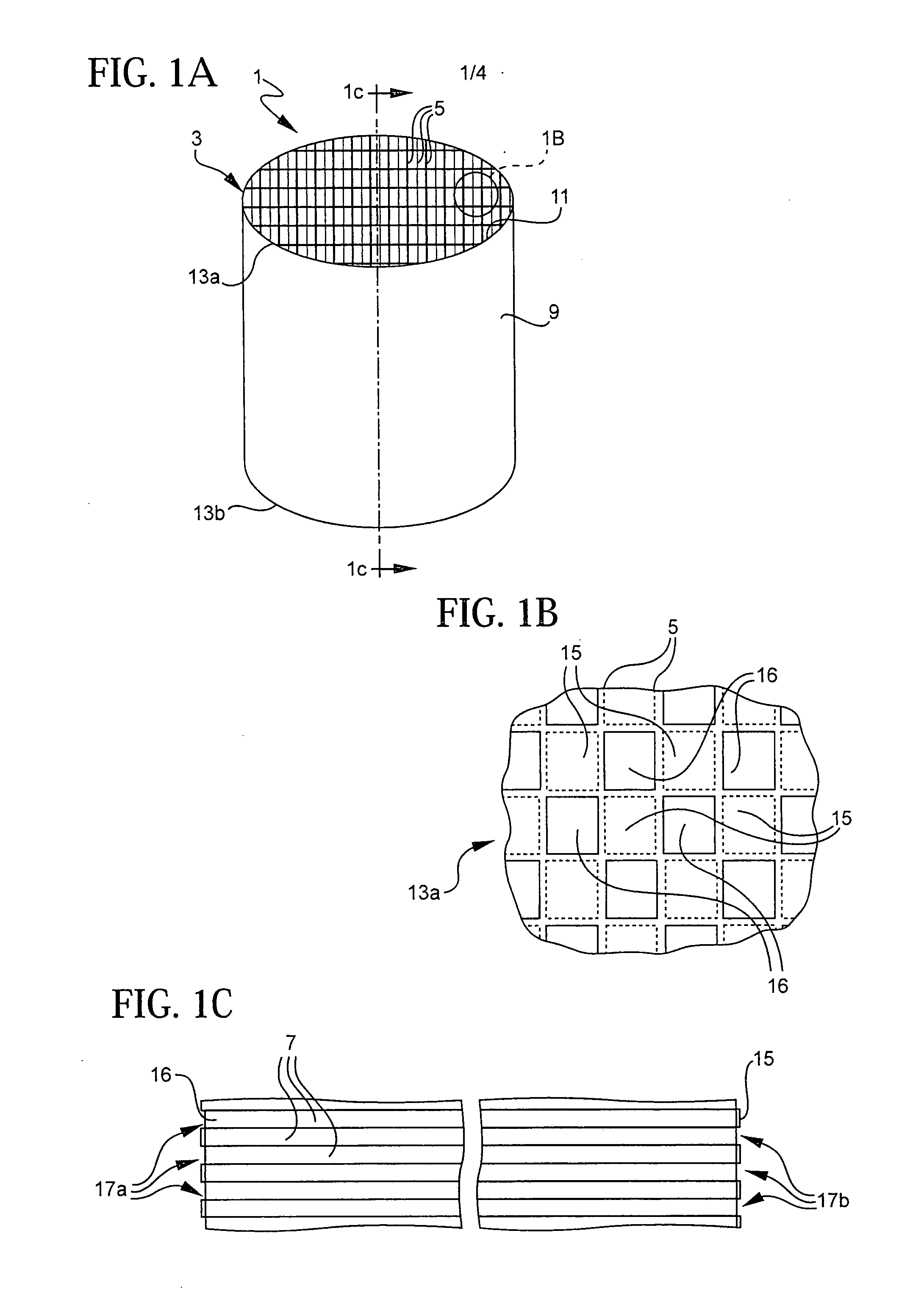

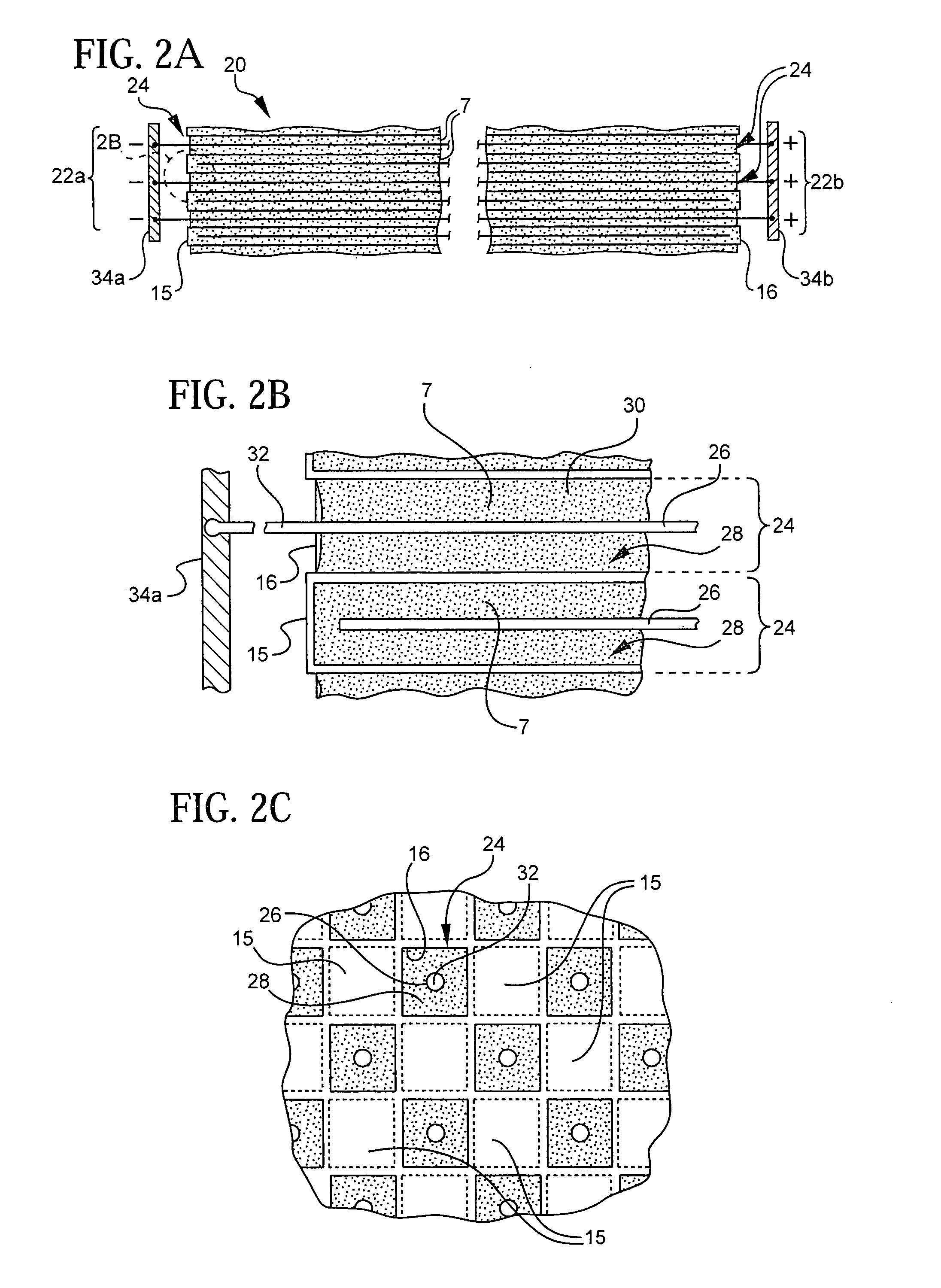

[0023]With reference to FIGS. 1A-1C, the invention is preferably applied to ceramic honeycomb substrates 1 of the type used as diesel particulate filters. Such substrates 1 include a network 3 of web walls 5 which define a plurality of elongated channels 7. While the channels 7 are illustrated as having a square cross-section in FIG. 1B, they may just as easily be hexagonal or some other polygonal shape. The web walls 5 forming the channels 7 are typically between 2.0 and 5.0 mils thick, and the density of the channels 7 may be between 300 and 2,000 channels per square inch. The ceramic substrate 1 further includes an outer skin 9 which is typically cylindrical in shape, and having a thickness of approximately three times that of the web walls 5. The network 3 of web walls 5 is integrally connected to the inner surface 11 of the outer skin 9. The honeycomb substrate 1 has generally planar opposing ends 13a, 13b as shown.

[0024]With particular reference to FIGS. 1B and 1C, the honeyco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com