A high-efficiency and energy-saving composite shape-setting phase change material and its preparation method

A technology of shape-setting phase change materials and composite materials, which is applied in the field of high-efficiency and energy-saving composite shape-setting phase change materials and its preparation, can solve the problems of poor bonding ability of inorganic substrate materials, low energy storage latent heat, and failure of energy storage functions. Achieve the effects of increasing the overall load capacity, low leakage energy storage efficiency, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

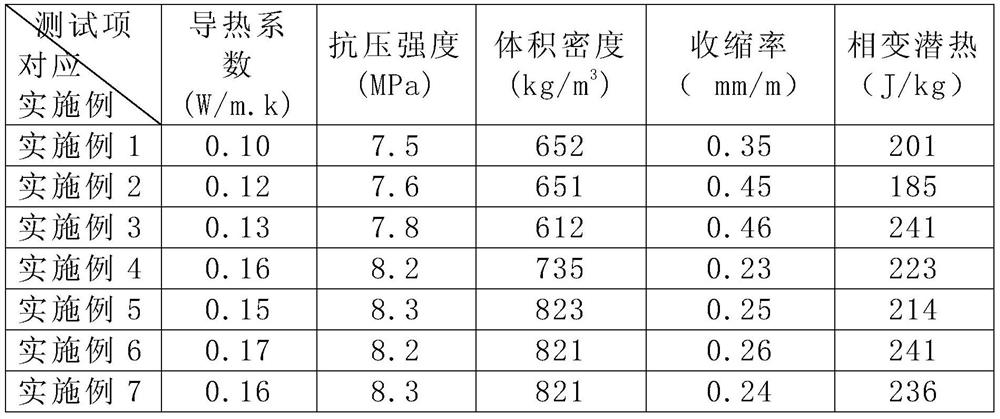

Examples

Embodiment 1

[0024] The high-efficiency and energy-saving composite shape-changing material of this embodiment includes the weight parts of the following components:

[0025] Sludge shale ceramsite porous material: 60; organic phase change composite material: 40; modified cement material: 20; the porosity of the above sludge shale ceramsite is between 50% and 55%; The phase change composite material is a mixture of polybasic fatty acid material and degradable polyester. The mass ratio of polybasic fatty acid material to degradable polyester is 1:0.2. The degradable polyester can be polyethylene glycol ester; The fatty acid material is a mixture of capric acid, lauric acid and palmitic acid, and the mass ratio of capric acid, lauric acid and palmitic acid is 1:0.5:0.7, so that the organic phase change composite material is adsorbed on the pores of sludge shale ceramsite Inside, and the modified cement is coated on the surface of the sludge shale ceramsite to form an encapsulation. The obta...

Embodiment 2

[0029] The high-efficiency and energy-saving composite shape-changing material of this embodiment includes the weight parts of the following components:

[0030] Sludge shale ceramsite porous material: 50; organic phase change composite material: 30; modified cement material polyvinylpyrrolidone modified cement: 25; make the porosity of the above sludge shale ceramsite 55% to 60% Between; the organic phase change composite material used is a mixture of polybasic fatty acid material and degradable polyglycidyl methacrylate, and the mass ratio of polybasic fatty acid material to degradable polyglycidyl methacrylate is 1:0.05; The polybasic fatty acid material is a mixture of capric acid, stearic acid and lauric acid, and the mass ratio of capric acid, stearic acid and lauric acid is 1:0.4:0.6, so that the organic phase change composite material is adsorbed on the sludge shale pottery In the pores of the granules, the modified cement is coated on the surface of the sludge shale c...

Embodiment 3

[0034] The high-efficiency and energy-saving composite shape-changing material of this embodiment includes the weight parts of the following components:

[0035] Sludge shale ceramsite porous material: 55%; organic phase change composite material: 35%; polymer propylene liquid emulsion modified portland cement: 15%; make the above sludge shale ceramsite porosity 60%-65 %, and make the specific surface area of sludge shale ceramsite 100m 2 / g; the organic phase change composite material used is a mixture of polybasic fatty acid materials and degradable polyglycidyl methacrylate, and the mass ratio of polybasic fatty acid materials to degradable polyglycidyl methacrylate is 1:0.1; The polybasic fatty acid material is a mixture of capric acid, stearic acid and methyl palmitate, and the mass ratio of capric acid, stearic acid and methyl palmitate is 1:0.2:0.3, and the organic phase change composite material is adsorbed on the sludge In the pores of the shale ceramsite, the modi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com