Packaging laminate, method of producing a packaging container and the packaging container

a technology of packaging container and packaging laminate, which is applied in the field of packaging laminate, can solve the problems of disturbed movement of the anvil jaw, poor mechanical settings of the sealing machine, and poor guiding of the tube, so as to reduce the sensibility reduce the melting enthalpy, and reduce the effect of the ultrasonic vibration heat sealing system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

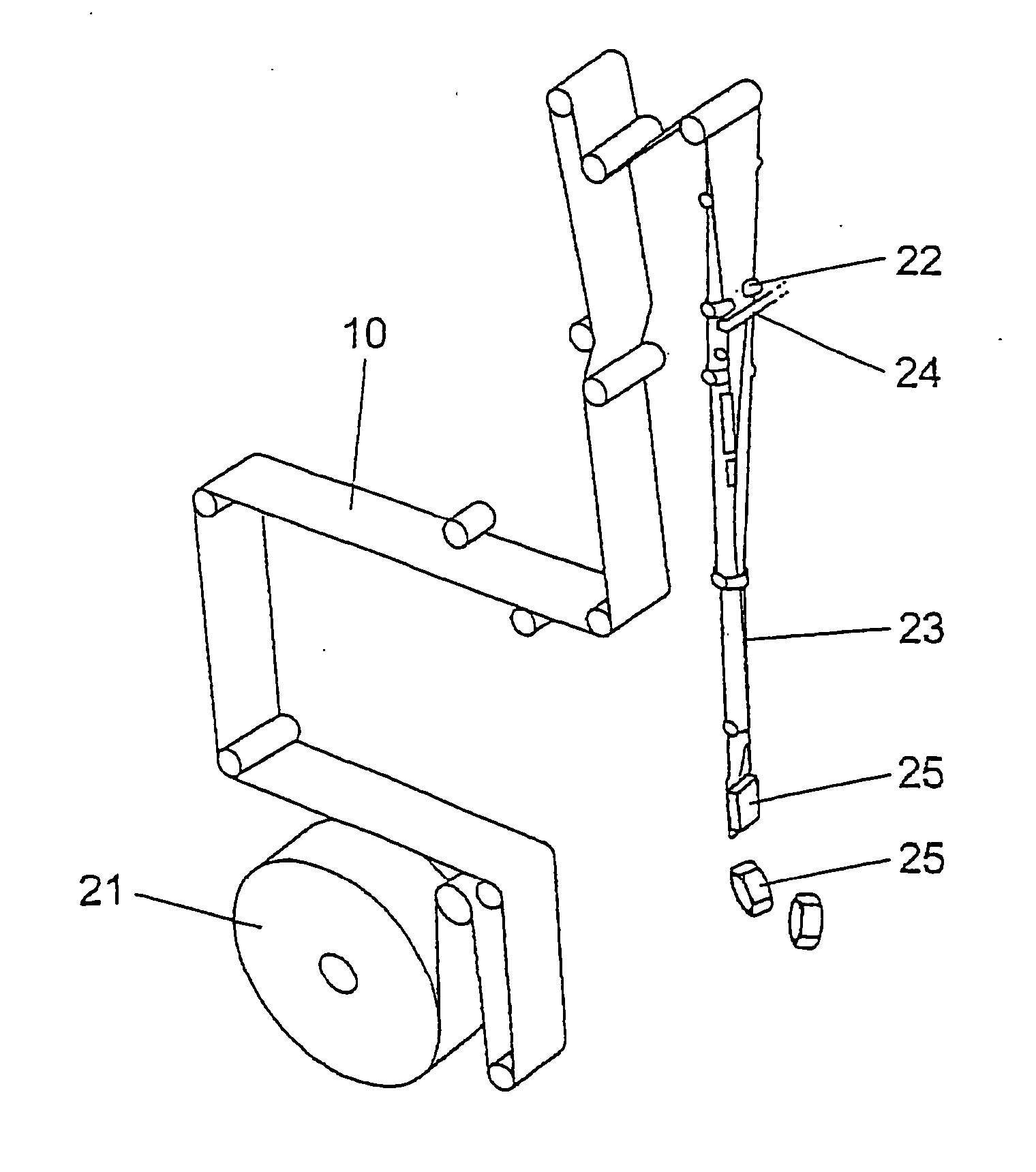

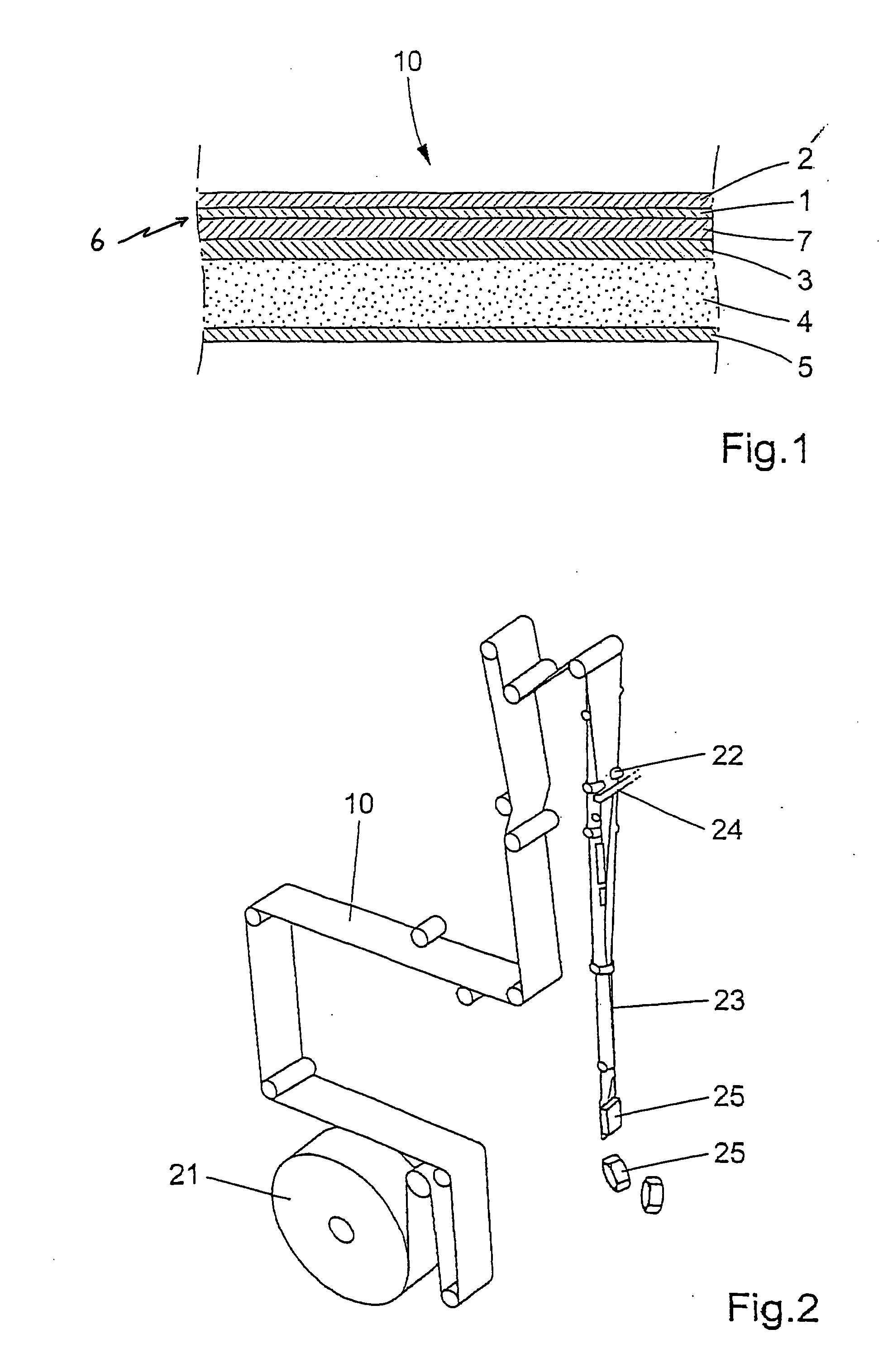

[0044] In the examples three different laminates according to the invention were tested and also one reference laminate of conventional type. The laminates are specified in table 1. L1 and L2 had been produced by laminating a film together with the paperboard / decor layer. The film of L1 consisted of a first, second and fourth ply according to the above description. The film of L2 consisted of a second and fourth ply. The reference and the L3 laminate had been produced by extrusion coating. In table 1, the numbering of the plies follows the numbering shown in FIG. 1. As is evident from table 1, an inside layer in a laminate according to the invention may comprise different numbers of plies, meaning that the first ply 1, the fourth ply 7 or the third ply 3 may be the ply which is arranged in direct contact with the second sealing ply 2.

TABLE 1ReferenceL1L2L3Sealing ply 2LDPE,Dow ExxonJPC Kernel,27 g / m2AffinityExceed32 g / m2PL1880,ML1023,5.4 g / m211 g / m2Melt enthalpy,120.8 J / g90 J / g110...

PUM

| Property | Measurement | Unit |

|---|---|---|

| time | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| melt enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com