Substrate-processing method and method of manufacturing electronic device

a technology of electronic devices and substrates, applied in the direction of instruments, photomechanical devices, optics, etc., can solve the problems of excessive processing time, attention not paid to the index that should be controlled,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0068]

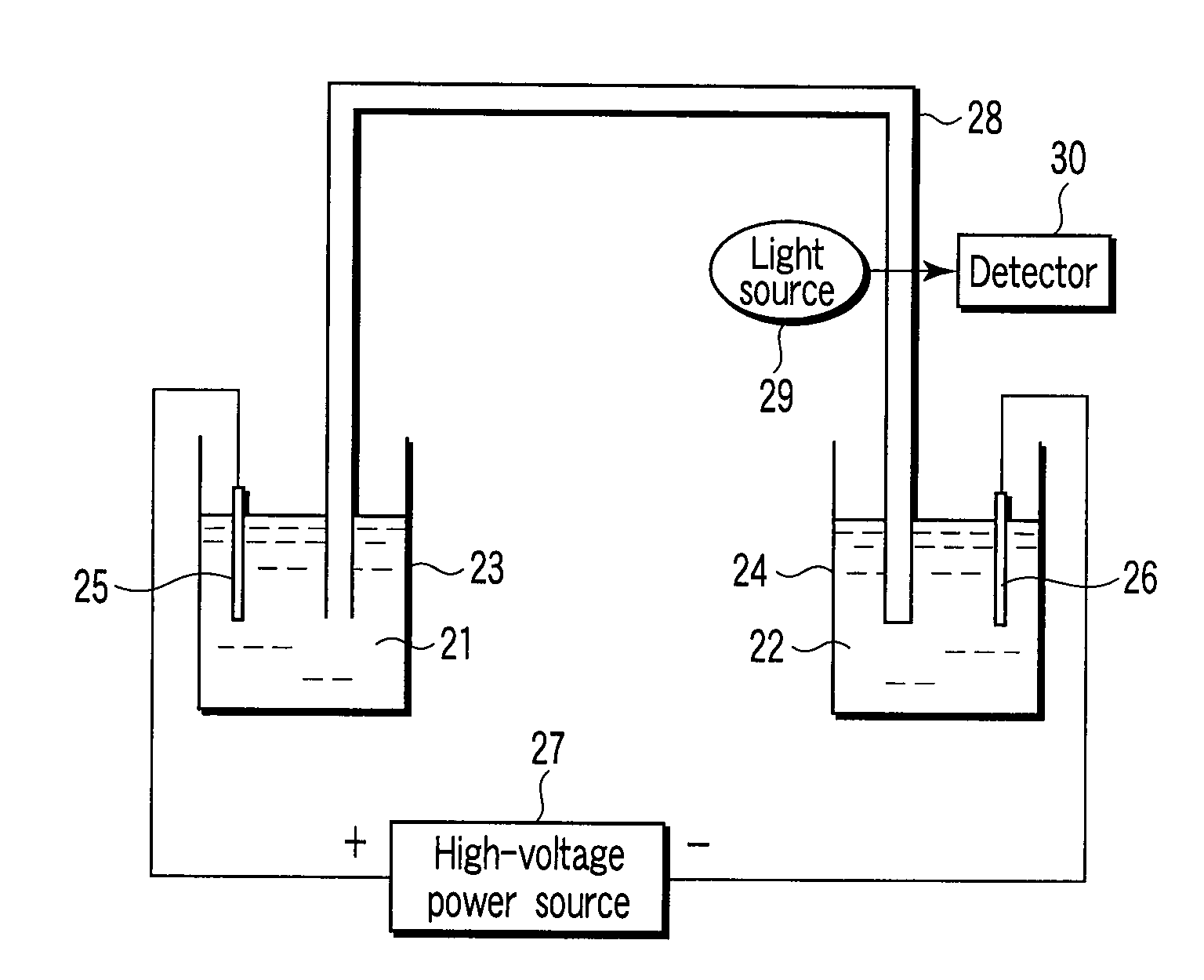

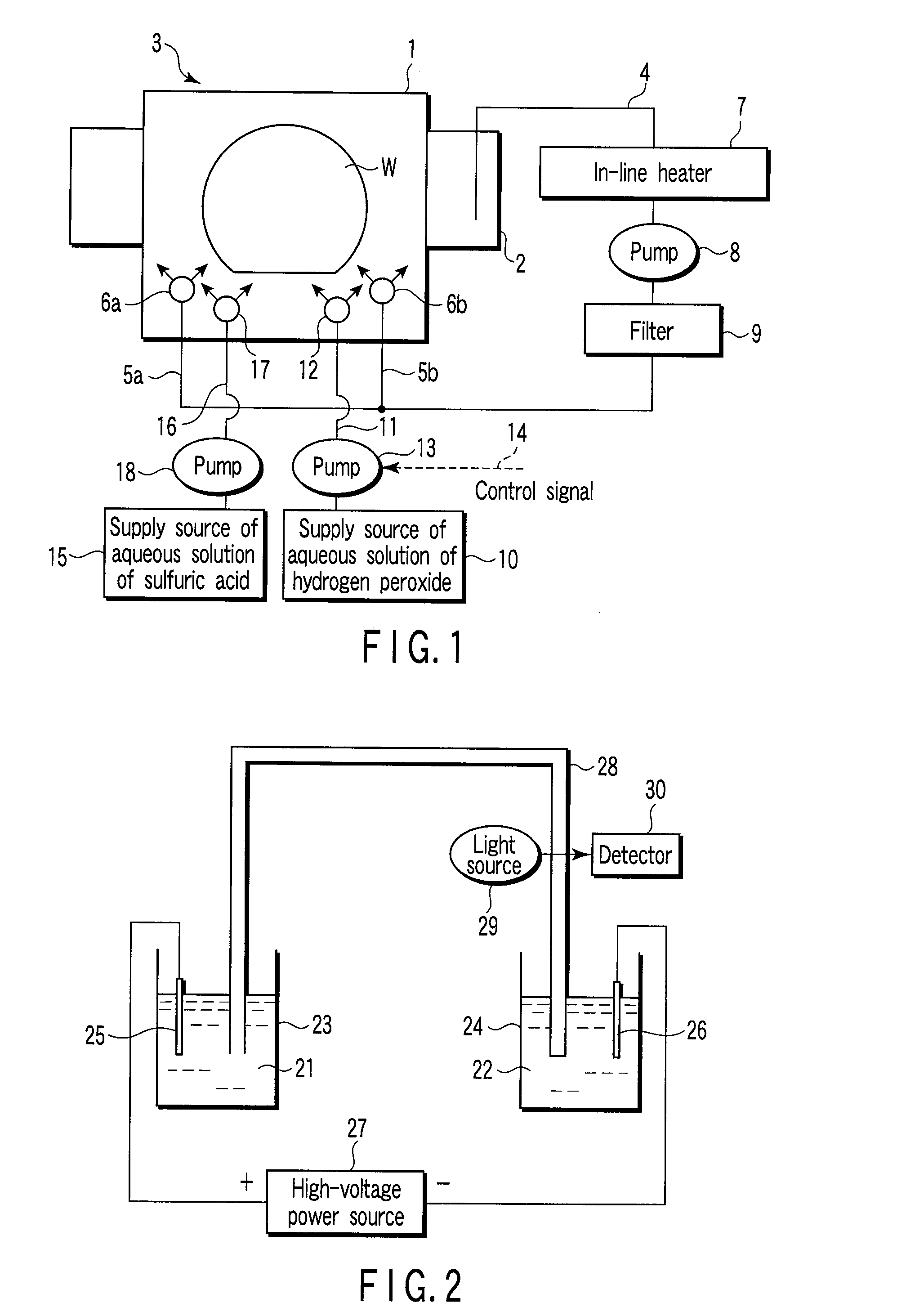

[0069]Solutions were prepared by dissolving in a distilled water quinolinic acid, hexadecyl trimethyl ammonium hydroxide (10% aqueous solution) and 2-amino-2-hydroxymethyl-1,3-propane diol. The solutions thus prepared were used as buffer solutions 21 and 22, respectively, so as to be accommodated in the anode vessel 23 and the cathode vessel 24 of the apparatus shown in FIG. 2. Then, a sample was prepared by mixing an aqueous solution containing 96 to 98% by weight of sulfuric acid with another aqueous solution containing 35% by weight of hydrogen peroxide. In mixing these two aqueous solutions for preparing the sample, the mixing ratio by weight was set at 1:1. The sample thus prepared was mixed with the buffer solution 21 accommodated in the anode vessel 23. Then, a DC voltage of −10 kV, −18 μA was applied from the high voltage power source 27 to the anode plate 25 and the cathode plate 26. After application of the DC voltage, the capillary tube 28 was irradiated with an ult...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com