Arabinose Isomerase Expressed From Corynebacterium Genus and Tagatose Manufacturing Method By Using It

a technology of arabinose isomerase and corynebacterium genus, which is applied in the field of arabinose isomerase gene, can solve the problem that the production of tagatose using recombinant i>e. coli/i> is not suitable for the production of tagatose as a food ingredien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

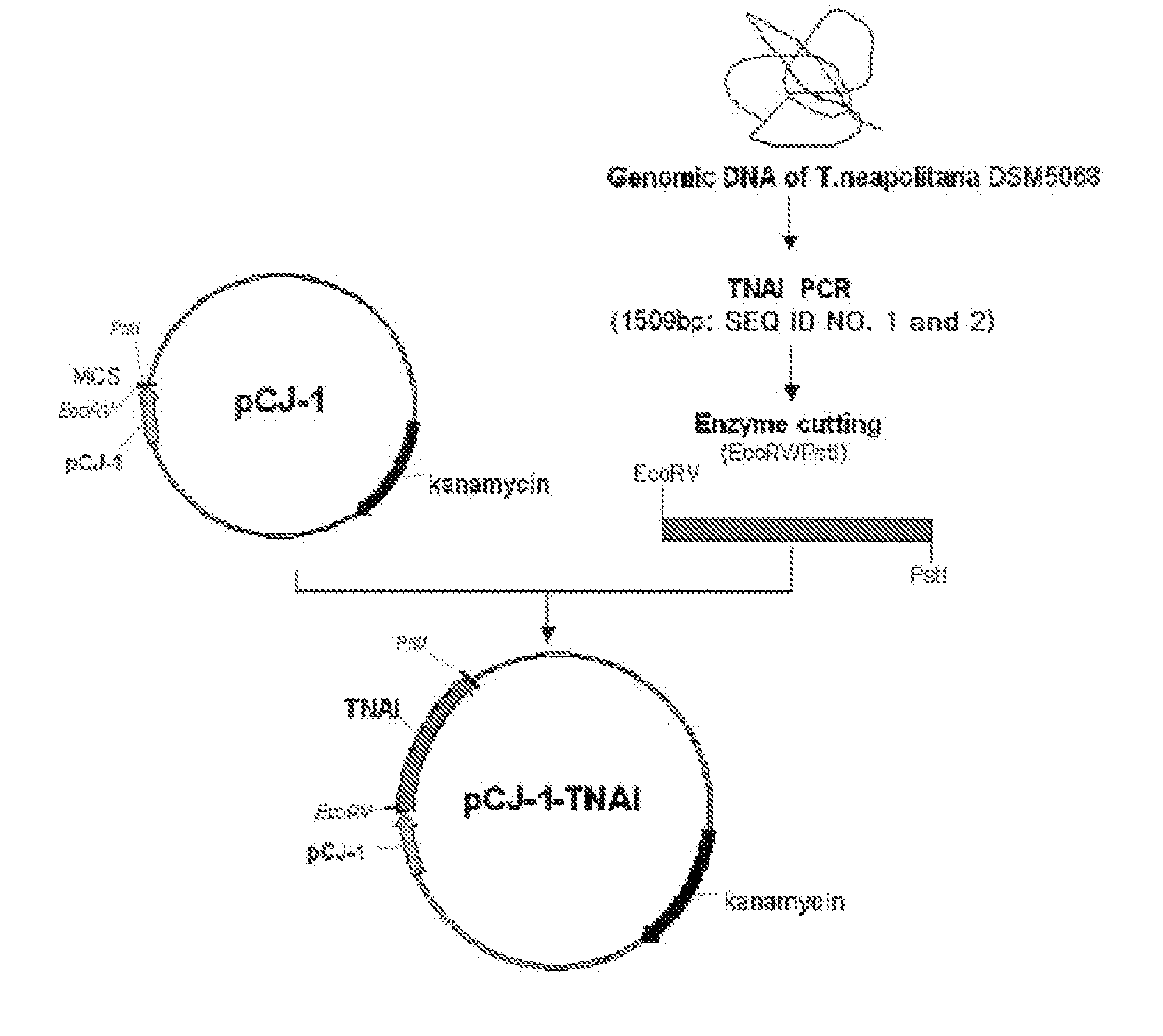

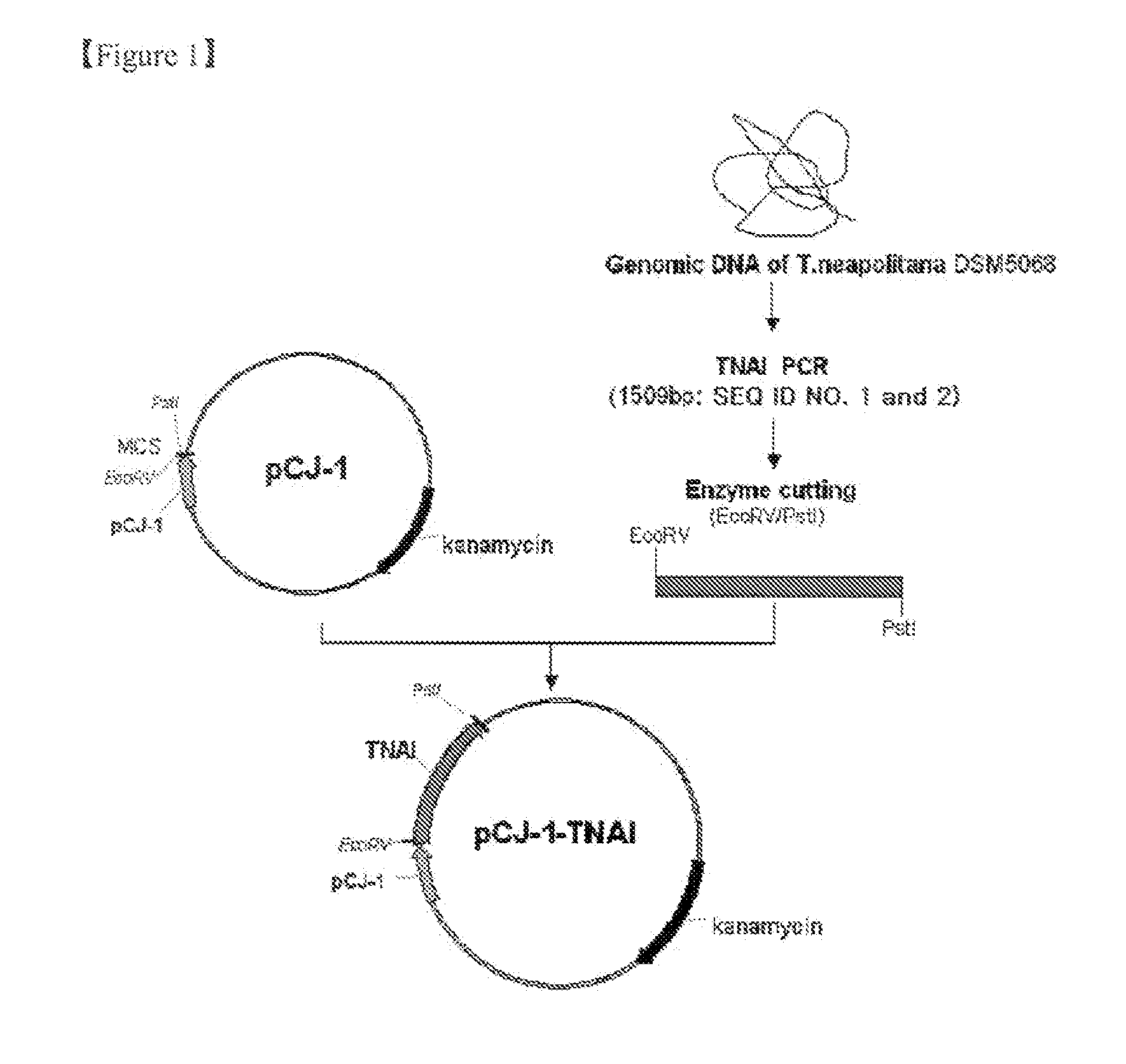

Cloning of the Arabinose Isomerase

[0035]Thermotoga neapolitana DSM 5068 was cultured under anaerobic conditions. Centrifugation was performed at 8,000×g for 10 minutes to recover the cultured cells. Genomic DNA was extracted from the obtained cells by using a Cell culture DNA Midi Kit (Qiagen, U.S.A.). Polymerase Chain Reaction (PCR) was performed with the genomic DNA buy using oligonucleotides 5′-CCCGA TATCATGATCGATCTCAAACAGTATGAG-3′ (SEQ. ID. NO: 1 ) and 5′- TGCACTGCAGTCATCT TTTTAAAAGTCCCC-3′ (SEQ. ID. NO: 2) with the insertion of EcoRV and Pst1 restriction enzyme site sequences as primers. PCR product was obtained by amplifying the 1509 bp DNA containing the Thermotogas neapolitana arabinose isomerase gene. To mass-produce the arabinose isomerase encoded by the amplified gene, two of the Corynebacterium sp. derived vectors exhibiting excellent protein overexpressing capacity were selected. The vectors were introduced into E. coli DH5alpha, which were deposited at the Korean Cultu...

example 2

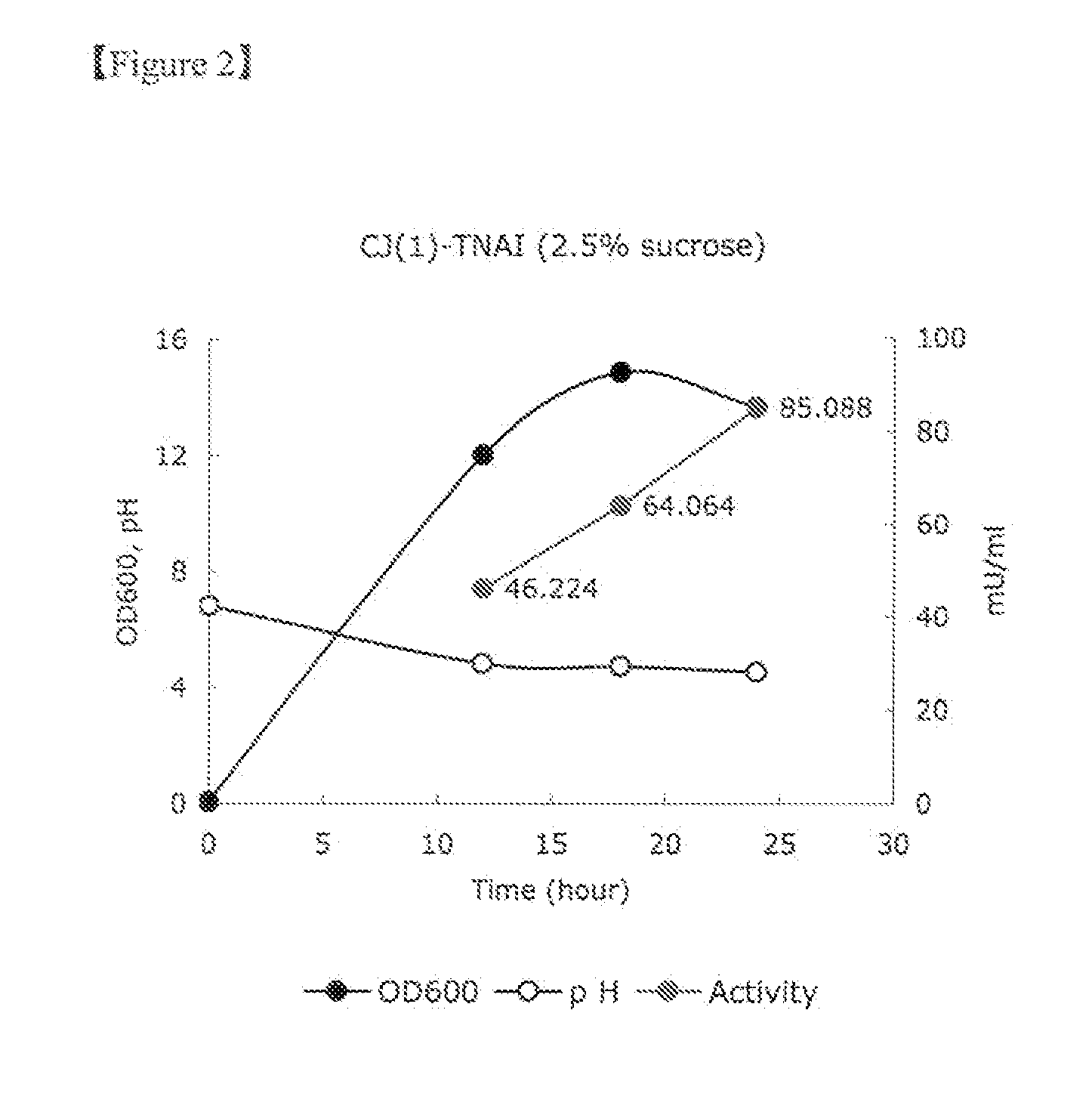

[0037]Expression of the Arabinose Isomerase in Corynebacterium the recombinant strains Corynebacterium glutamicum CJ-1-TNAI and Corynebacterium glutamicum CJ-7-TNAI (Accession Nos: KCCM10786P and KCCM10787P) prepared in Example 1 were inoculated in MB medium (Bacto-trypton 10 g / L, bacto-yeast extract 5 g / L, NaCl 10 g / L, Soytone 5 g / L) containing 10 μg / Me of kanamycin at the concentration of OD600=0.1, followed by culture at 30° C. for 24 hours to induce expression of the recombinant arabinose isomerase. To measure the enzyme activity of the expressed arabinose isomerase, the culture solution was centrifuged at 8,000×g for 10 minutes and cells were recovered. The cells were resuspended in 50 mM Tris-HCl (pH 7.0) buffer, followed by ultrasonification to lyse the cells. The supernatant was obtained as a crude enzyme solution, with which galactose isomerization was performed. Particularly, for the isomerization, 100 μl of an enzyme solution containing 40 mM of galactose as a substrate w...

example 3

Optimization of the Culture Condition for Mass-Production of the Recombinant Strain

[0038]The recombinant strains prepared in Example 2 were inoculated in MB medium (Bacto-trypton 10 g / L, bacto-yeast extract 5 g / L, NaCl 10 g / L, Soytone 5 g / L) containing 10 μg / Ml of kanamycin at the primary concentration of OD600=0.6. The growth of the strains in two basic media for the culture of Corynebacterium, MB medium (Bacto-trypton 10 g / L, bacto-yeast extract 5 g / L, NaCl 2.5 g / L, Beef extract 5 g / L), was investigated. Temperature dependent (25° C., 30° C., 37° C.), pH dependent, glucose (carbon source) and sucrose concentration dependent growths in the two media were compared. In addition, the growths under the various conditions and the expression levels of the enzyme thereby were measured every hour to judge the optimum expression condition for mass-production of the recombinant arabinose isomerase (Tables 2 and 3).

TABLE 2ModifiedmediumMB mediumAerobicAerobicStationary25° C.30° C.37° C.OD6001...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reaction temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com