Controlled nanowire in permanent integrated nano-templates and method of fabricating sensor and transducer structures

a technology of controlled nanowires and integrated nano-templates, which is applied in the field of controlled nanowires in permanent integrated nano-templates and the method of fabricating sensor and transducer structures, can solve the problems of nanowires produced, difficult to assemble wires into rational device geometries, and excluding the opportunity for nanoscale phenomena such as quantum confinemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

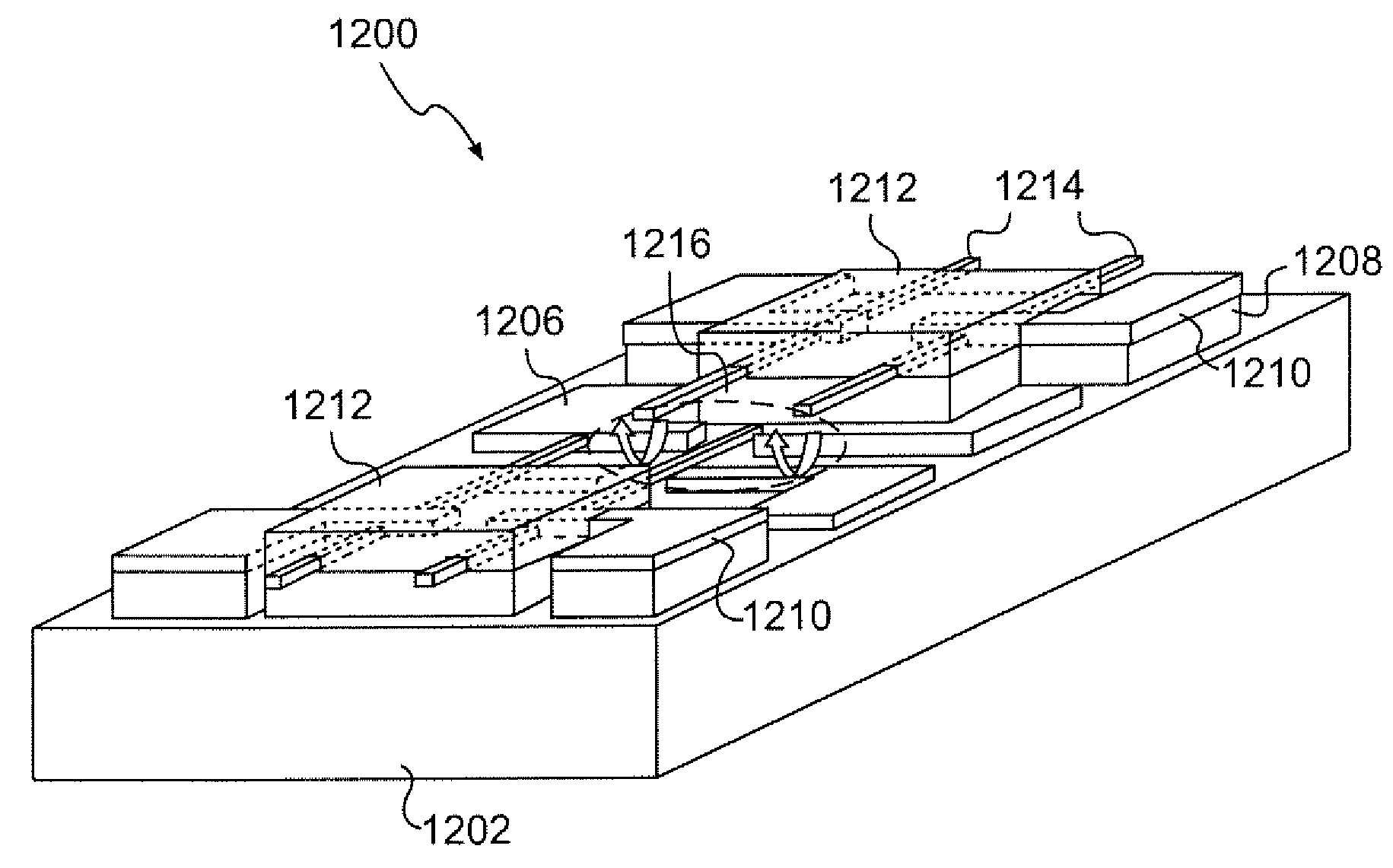

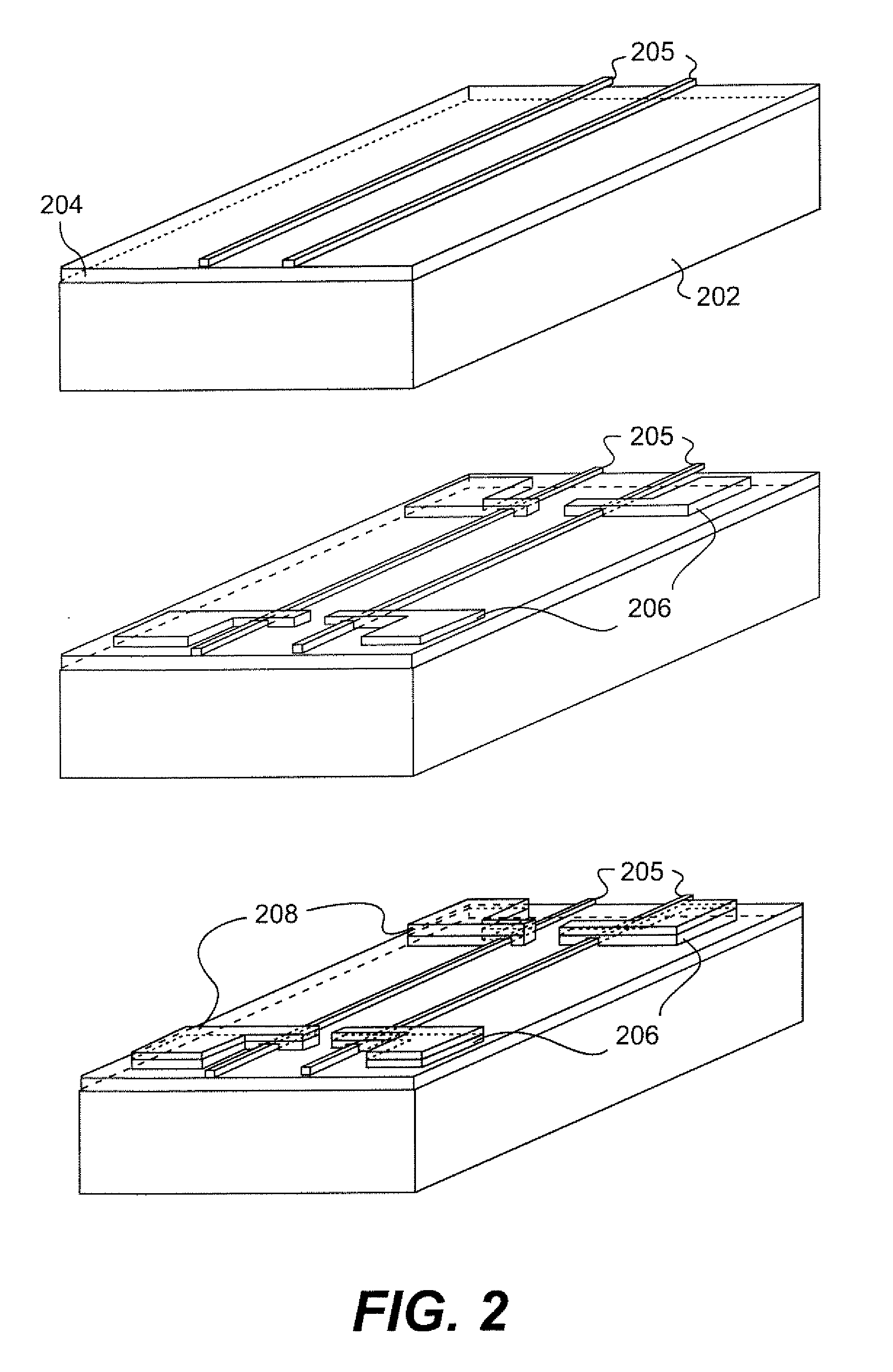

[0047]This invention presents a novel method to form uniform or heterogeneous, straight or curved and size-controllable nanostructures including, for example, nanowires, nanoribbons, nanotubes, and nanotapes (e.g., high width to height ratio cross-section) including single crystal SiNW, in a nanochannel template. In the case of semiconductor nanowires, doping can be included during growth. Electrode contacts are present as needed and may be built in to the template structure. Thus, completed devices such as diodes, transistors, solar cells, sensors, and transducers are fabricated, contacted, and arrayed as nanostructure and resultant device fabrication is completed. Optionally, the template is not removed and may become part of the structure.

[0048]Nanochannel templates are fabricated by the combined use of lithography and sacrificial material patterning techniques known in the art. The nanochannels can be straight or curved, as desired, and the sizes are controllable. Hence the nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| critical diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com