Temperature-switched process for wafer backside polymer removal and front side photoresist strip

a technology of photoresist strip and temperature-switched process, which is applied in the direction of electrical discharge tubes, decorative arts, electrical equipment, etc., can solve the problems of affecting the workpiece temperature, so as to achieve the effect of increasing the temperature of the workpi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

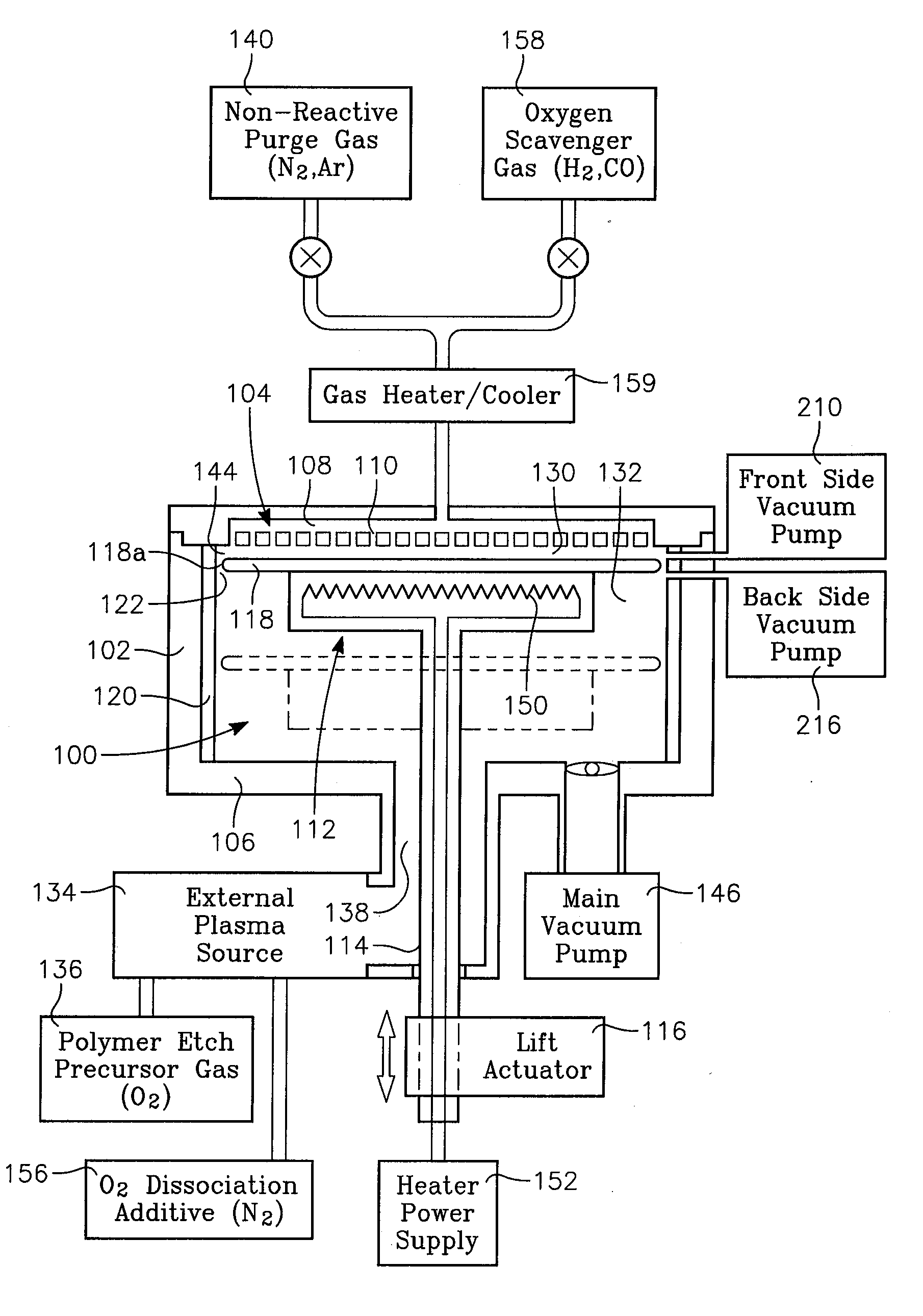

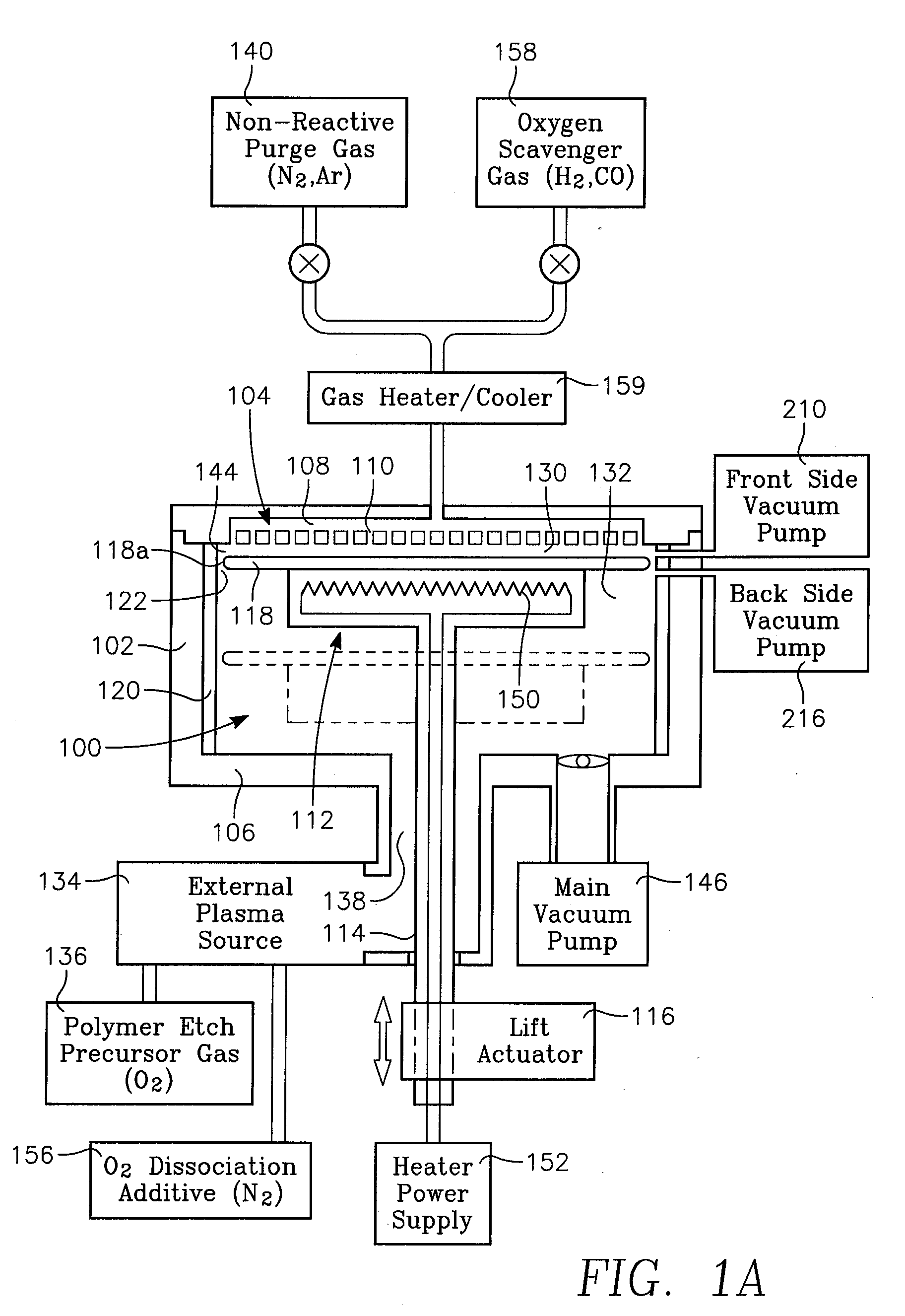

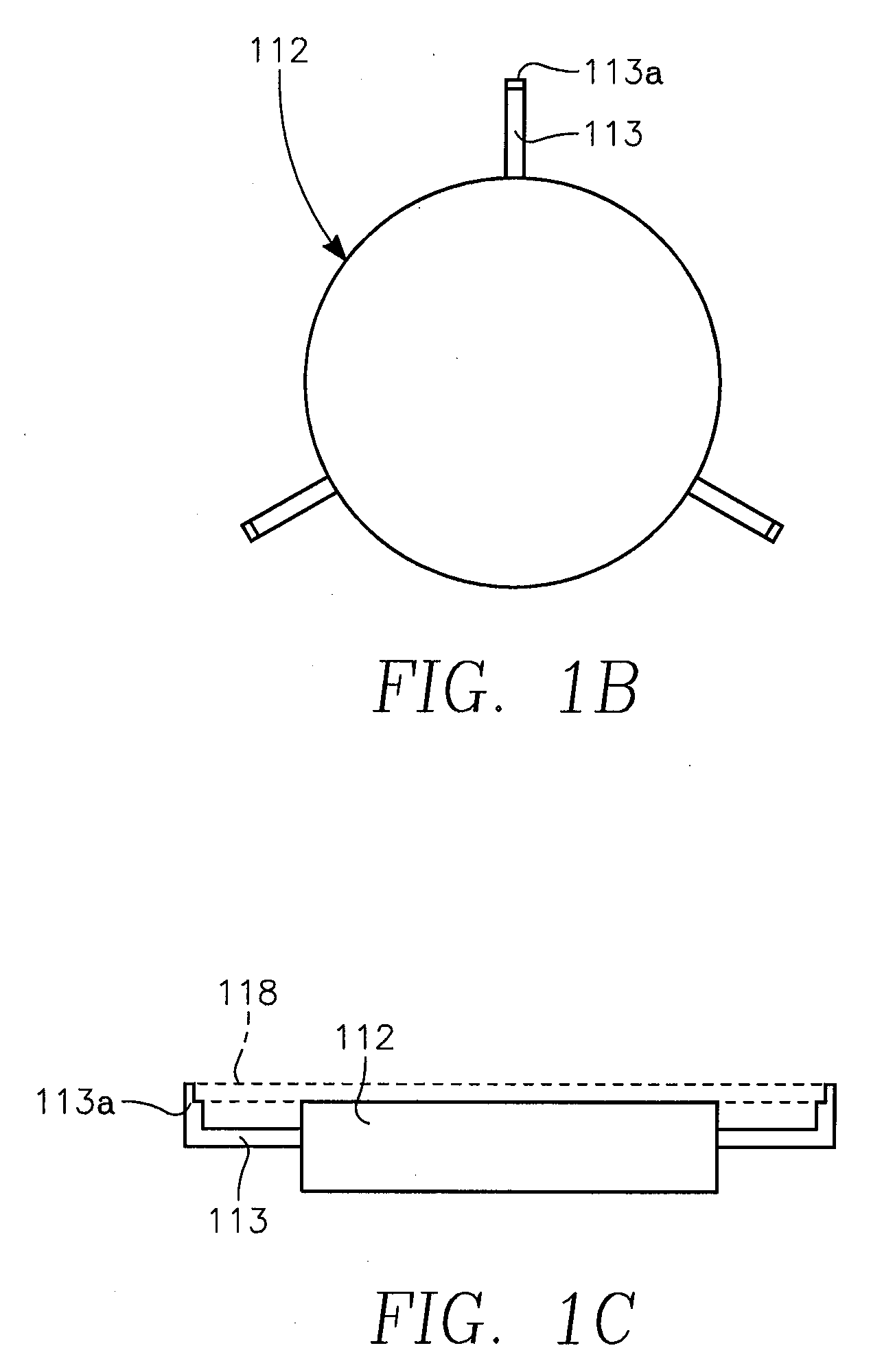

[0035]Exemplary embodiments of the invention pertain to removing polymer from the backside edge of a wafer without damaging critical films, such as an ultra low-K dielectric film, by heating the wafer in a chamber while exposing only the backside of the wafer to polymer etch radicals or plasma by-products, such as atomic or free oxygen, from an external plasma source. The oxygen radicals may be provided by an external plasma source which is supplied with an oxygen-containing gas or vapor, such as O2, H2O, N2O, CO2, or CO, for example. The oxygen-containing gas may be combined or diluted with other gases such as H2, N2 or Ar. Other fluorine-containing gases (such as CF4 or NF3) may be added to allow removal of polymer films that contain other materials (such as Si) and are not etched efficiently in O chemistry alone. The critical films in the thin film structure on the wafer front side are protected from damage by the polymer etch species by pumping purge gases across the wafer front...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com