Process for producing liqefied natural gas from high co2 natural gas

a natural gas and high co2 technology, applied in the direction of liquefaction, gaseous fuels, lighting and heating apparatus, etc., can solve the problems of inability to make a perfect separation between cosub>2/sub> and cosub>2/sub>, and the membrane cannot make a perfect separation between cosub>2 and cosub>2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

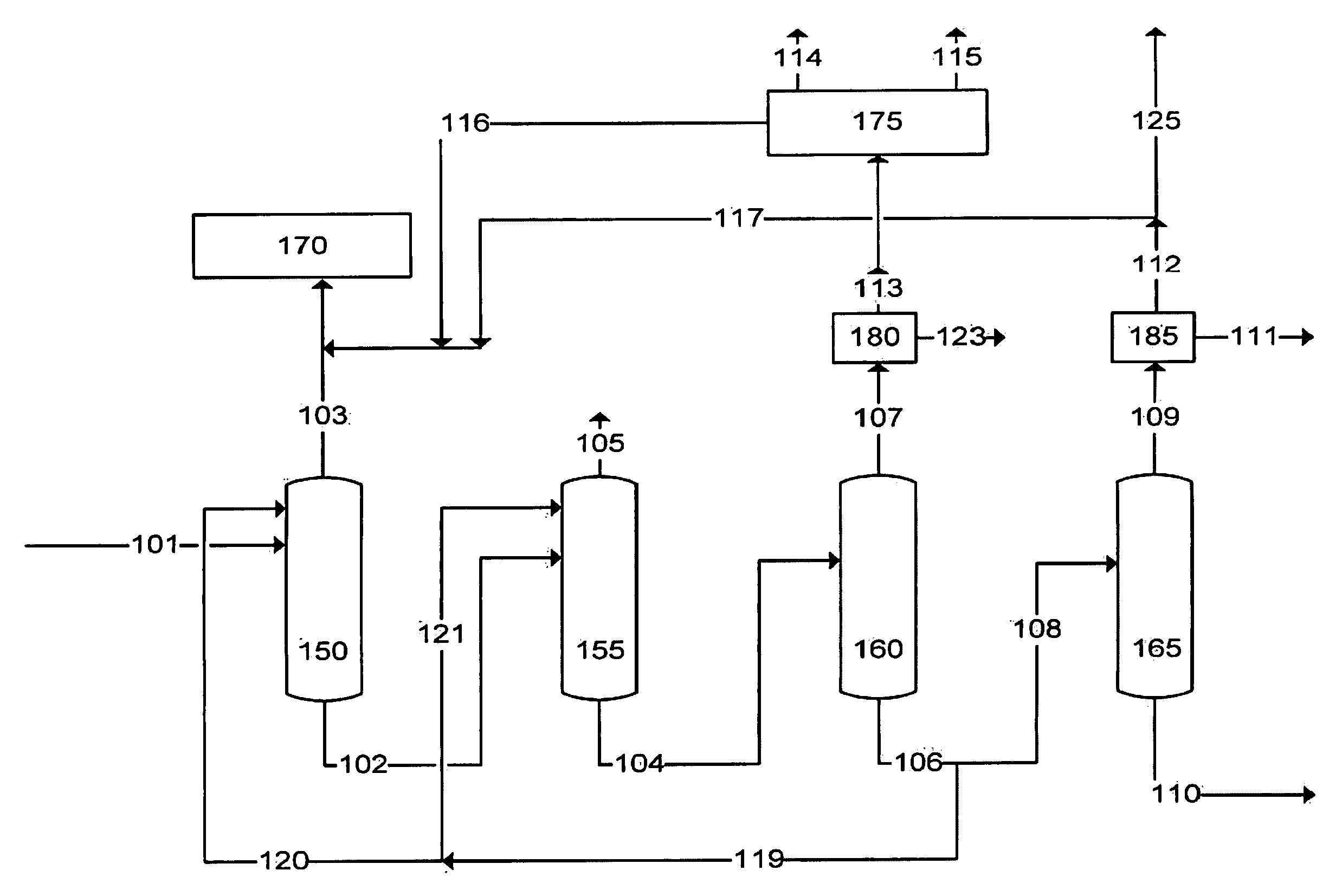

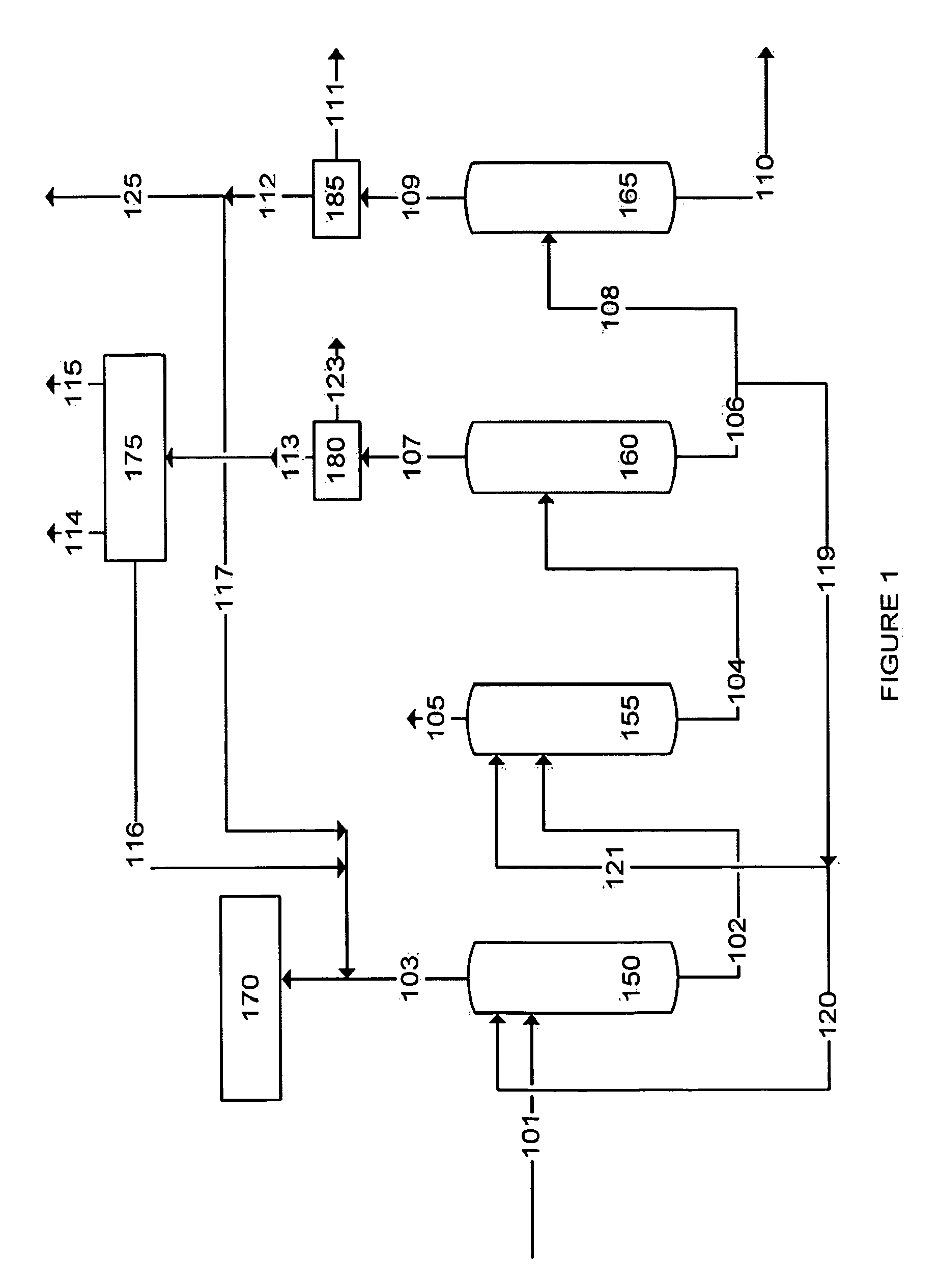

[0034]In an embodiment of the invention illustrated in FIG. 1, a hydrocarbon feed stream 101, having a composition as shown in TABLES 1 & 2 (simulated data), is fed to a demethanizer (DeC1) column 150. The DeC1 column 150 may be a packed or trayed-type distillation column equipped with a bottom reboiler, side reboilers, and a condenser, that is designed to process at least two feed streams: a light hydrocarbon feed gas stream and a heavy hydrocarbon liquid solvent stream. The operating pressure of the DeC1 column is in the range of about 38 to about 45 bar. The operating temperature of the overhead condenser is in the range of about −91 to about −84° C.

[0035]A hydrocarbon recycle stream 120 from the bottoms of a depropanizer (DeC3) column 160 is also fed into the DeC1 column 150. Essentially, the hydrocarbon recycle stream 120 is fractionated gas components passed from the plurality of separation processes as further described below. The hydrocarbon recycle prevents the CO2 from fre...

second embodiment

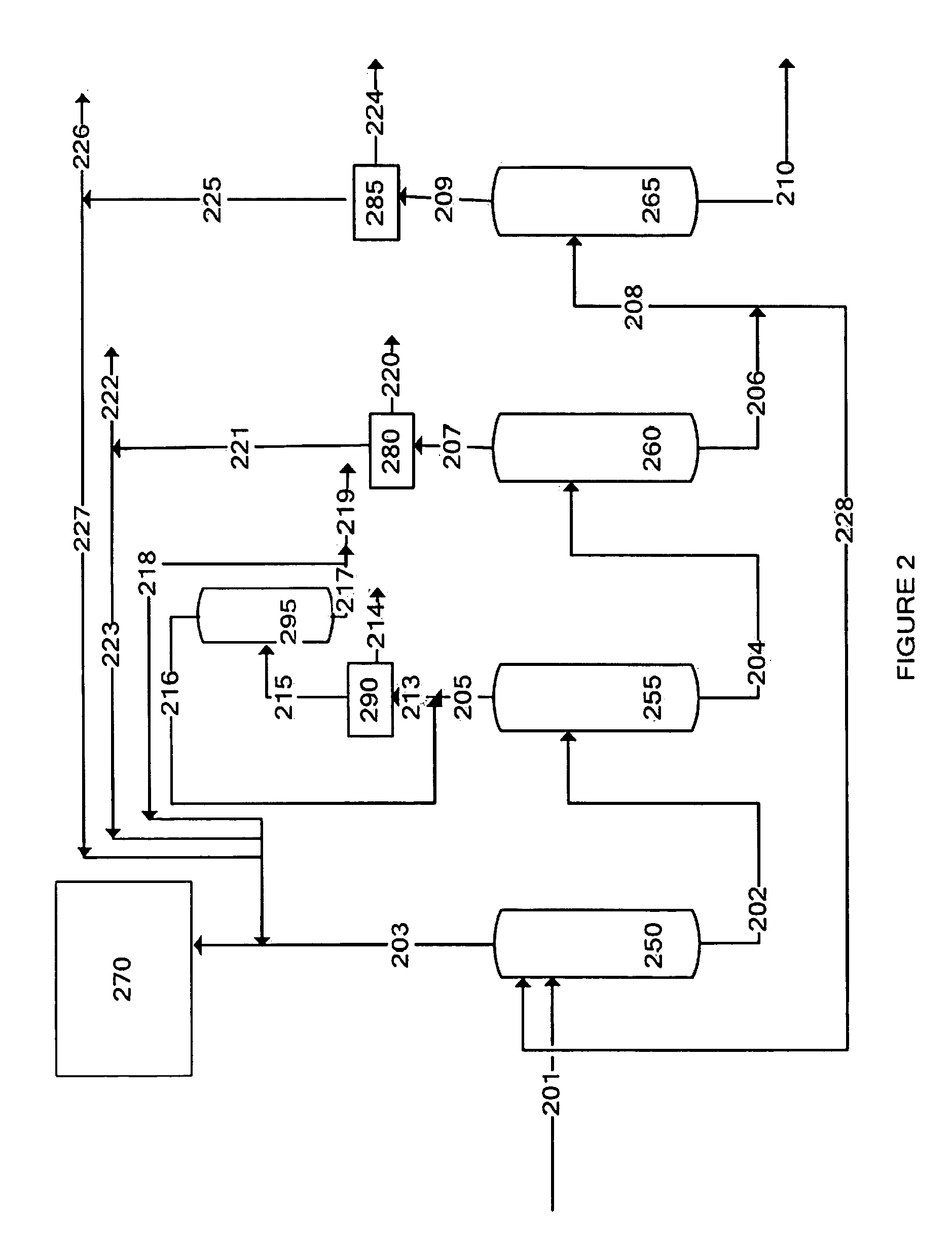

[0051]In another embodiment of the invention as illustrated in FIG. 2, a hydrocarbon feed stream 201, having a composition as shown in TABLES 3 & 4 (simulated data), is fed to a DeC1 column 250. The DeC1 column 250 is similar to that described above. The operating pressure of the DeC1 column 250 is in the range of about 38 to about 45 bar. The operating temperature of the overhead condenser is in the range of about −91 to about −84° C.

[0052]A hydrocarbon recycle stream 228 from the bottoms of a DeC3 column 260 is also fed into the DeC1 column 250. The hydrocarbon recycle prevents the CO2 from freezing and acts as a scrubbing agent to remove aromatics and other heavy hydrocarbons from the C1-rich product stream taken overhead.

[0053]Methane is taken as the principal overhead product, stream 203, and has the composition as shown in TABLE 3. The separated methane contains less than about 100 ppm CO2 and less than about 3 ppm H2S. Also, a full liquid reflux on the separated methane is fe...

third embodiment

[0067]In another embodiment of the invention as illustrated in FIG. 3, a hydrocarbon feed stream 301, having a composition as shown in TABLES 5 & 6 (simulated data), is fed to a DeC1 column 350.

[0068]The DeC1 column 350 is similar to that described above. The operating pressure of the DeC1 column 350 is in the range of about 38 to about 45 bar. The operating temperature of the overhead condenser is in the range of about −91 to about −84° C.

[0069]A hydrocarbon recycle stream 312 from the bottoms of a DeC3 column 360 is also fed into the DeC1 column 350. The hydrocarbon recycle prevents the CO2 from freezing and acts as a scrubbing agent to remove aromatics and other heavy hydrocarbons from the C1-rich product stream taken overhead. Also, a full liquid reflux on the separated methane is fed back to the demethanizer 350.

[0070]Since the aromatics are reduced to such a low level and the temperature is very cold, the majority of stream 303 may be fed to a MCHE 370. The MCHE is similar to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com