ERI configuration phosphorous-aluminum molecular sieve membrane, preparation method and applications thereof

A phospho-aluminum molecular sieve, molecular sieve technology, applied in molecular sieve and alkali exchange of phosphate, separation method, molecular sieve characteristic silicoaluminophosphate and other directions, can solve the problem of difficulty in preparing pure-phase SAPO-17 molecular sieve, unfavorable large-scale preparation, time required Long and other problems, to achieve the effect of shortening the crystallization time, high carbon dioxide separation performance, and complete coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1: SAPO-17 seed crystal preparation

[0051] Mix the template agent cyclohexylamine (CHA), aluminum isopropoxide, phosphoric acid and an appropriate amount of ultrapure water evenly, stir vigorously at room temperature for 1 hour, and then add T-type molecular sieves (200 nm, Si / Al= 3.2) As a silicon source. The sol was stirred and aged for 1-12 hours, the formed Al 2 o 3 -P 2 o 5 -SiO 2 -CHA-H 2 The molar ratio of each component in the O stable sol system is: P 2 o 5 / Al 2 o 3 = 1.0, CHA / Al 2 o 3 = 1.0, SiO 2 / Al 2 o 3 =0.1,H 2 O / Al 2 o 3 =50; the above sol was poured into a polytetrafluoroethylene-lined stainless steel reactor, and then the reactor was placed in an oven at 200°C for crystallization for 24 hours. The reaction product was separated by centrifugation, washed and dried, and then placed in a muffle furnace at 470°C for 6 h to remove the template agent to obtain the SAPO-17 molecular sieve.

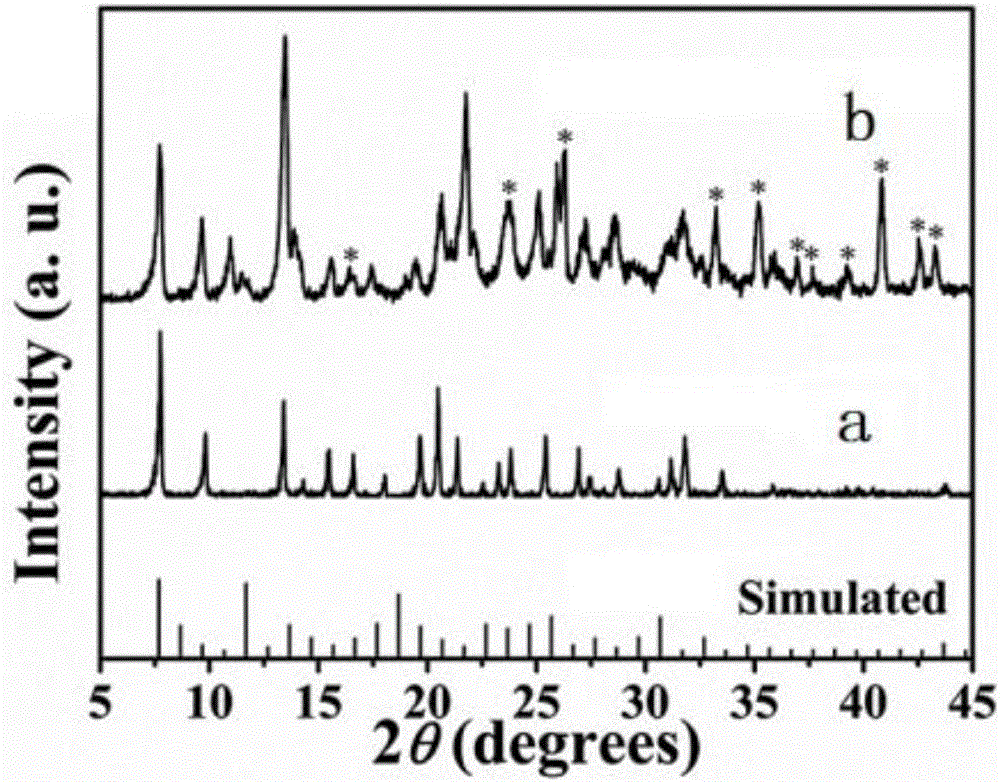

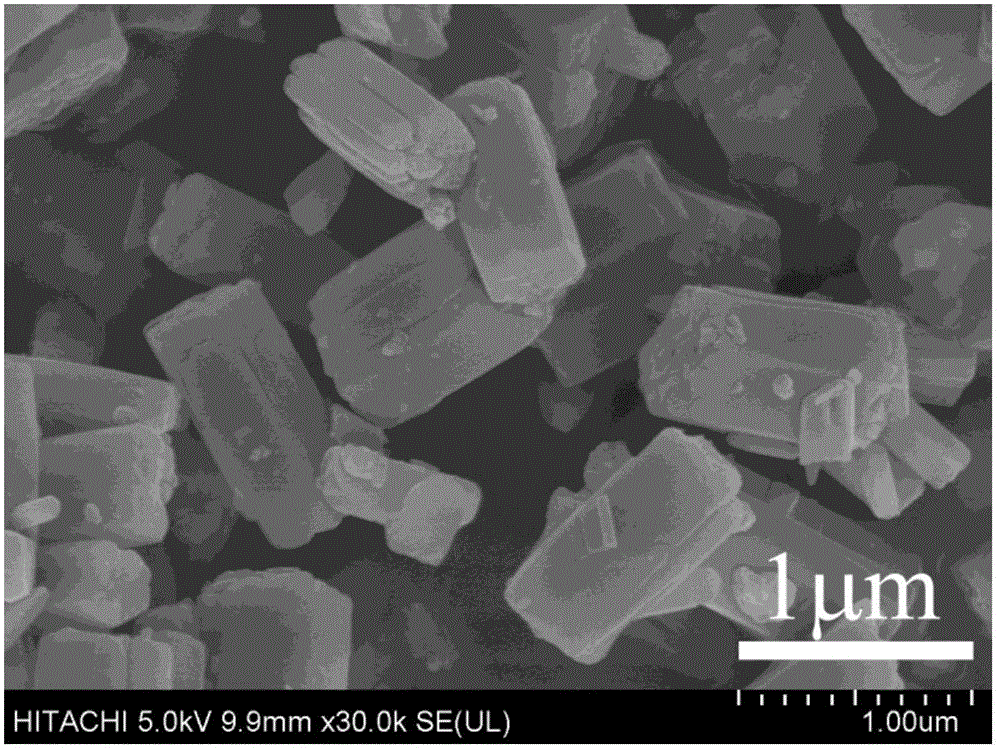

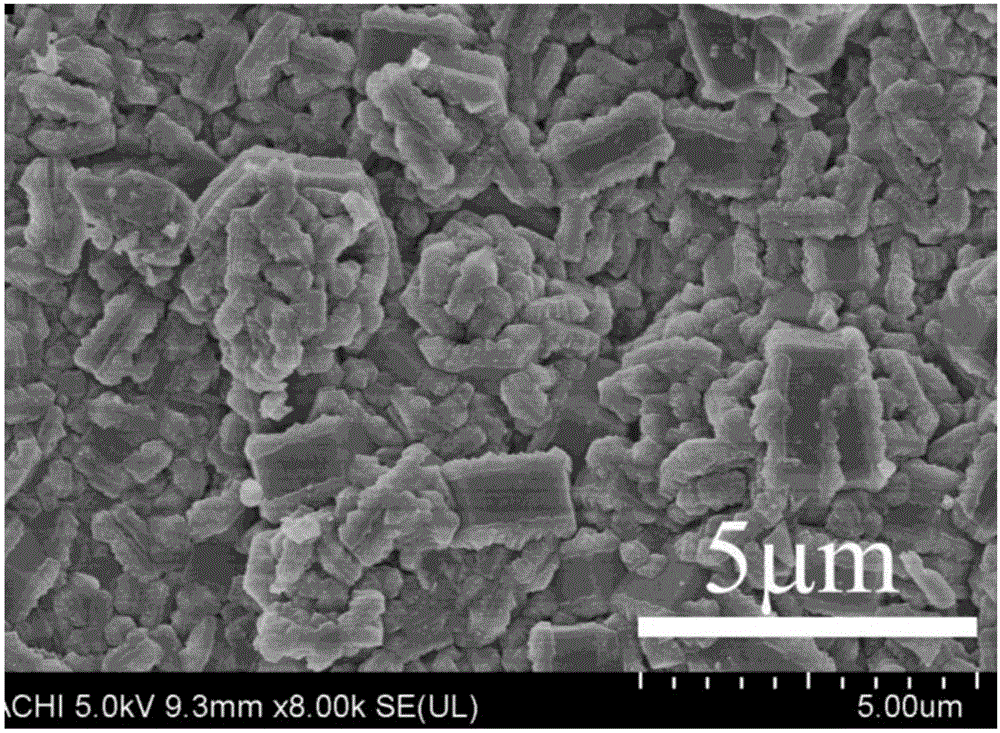

[0052] The samples were characteriz...

Embodiment 2

[0053] Embodiment 2: Preparation of SAPO-17 molecular sieve membrane

[0054] The preparation of SAPO-17 molecular sieve membrane, the steps are as follows:

[0055] (1) support body pretreatment: the support body adopts the tubular mullite produced by Japan Nikkato Co., Ltd. (the composition is 67wt.%Al 2 o 3 and 33wt.% SiO 2 ) carrier with an average pore diameter of 1.3 μm and a porosity of 43%. After the support body was smoothed with 1000-grit sandpaper, it was cleaned with ultrasonic waves in deionized water and dried. Evenly coat the ground SAPO-17 molecular sieve seeds on the outer surface of the support, and the seed crystal loading density is 0.5-2mg / cm 2 .

[0056] (2) Preparation of SAPO-17 molecular sieve membrane: Mix the template agent (SDA) cyclohexylamine, aluminum sec-butoxide, phosphoric acid and ultrapure water, stir and age for 12 hours to form a uniform and stable sol, each component in the sol system The molar ratio is: P 2 o 5 / Al 2 o 3 = 1.0,...

Embodiment 3

[0063] Embodiment 3: Preparation of SAPO-17 molecular sieve membrane

[0064] Synthesize SAPO-17 molecular sieve membrane according to the method substantially identical with embodiment 2, difference is template agent (SDA) is N,N,N,N-tetramethyl-1,6-hexamethylene diammonium, and sol proportion is each The molar ratio of the components is: P 2 o 5 / Al 2 o 3 = 1.0, SDA / Al 2 o 3 =0.8,H 2 O / Al 2 o 3 =500, the synthesis time is 100h.

[0065] The synthesized molecular sieve membrane M2 was used at 25°C, CO 2 / CH 4 (50 / 50) and CO 2 / N 2 The gas separation performance was characterized in the (50 / 50) system, and the results of the gas separation experiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com