Exhaust gas purifying apparatus for internal combustion engine

a technology for exhaust gas purification and internal combustion engines, which is applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of deterioration of added quantity, erroneous computation of nox purifying ratio, and inability to accurately compute nox purifying ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

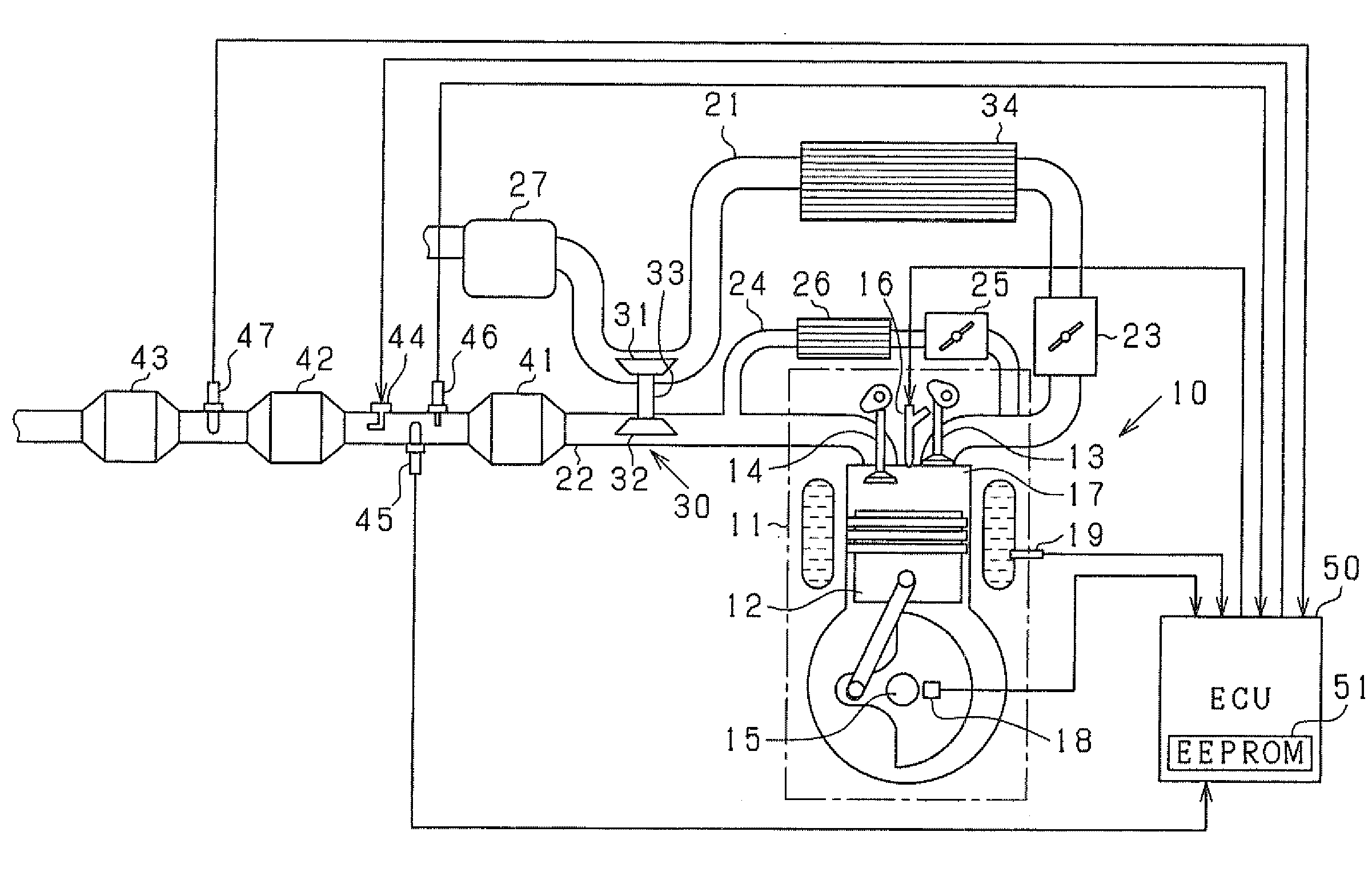

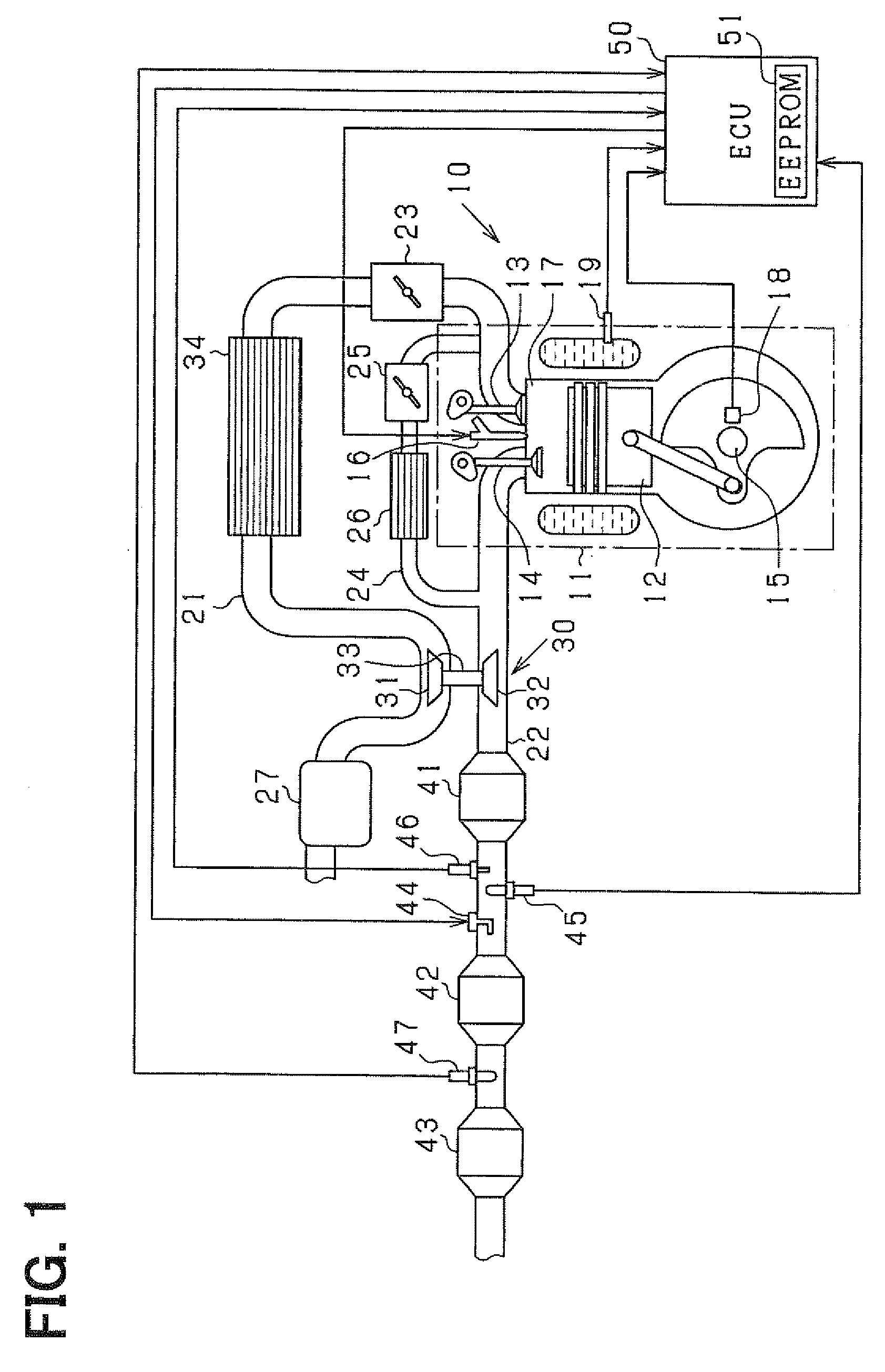

[0037]Hereafter, an embodiment of the present invention is described. In this embodiment, a multi-cylinder diesel engine is controlled. An electronic control unit (ECU) performs a various kind of controls to the engine. The diesel engine has a common-rail fuel injection system and a urea SCR system, Referring to FIG. 1, the system is schematically explained, hereinafter.

[0038]The engine 10 includes an engine body 11 which has a piston 12, an intake valve 13, and an exhaust valve 14. A reciprocative movement of the piston 12 rotates a crankshaft 15. A fuel injector 16 is provided on a cylinder head with respect to each cylinder. The fuel injector 16 injects fuel into a combustion chamber 17 directly, which is combusted in the combustion chamber 17.

[0039]The crankshaft 15 is provided with a crank angle sensor 18 which detects a rotation of the crankshaft 15. A cylinder block is provided with a coolant temperature sensor 19 which detects coolant temperature.

[0040]A fuel supply system w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com