Process for producing tissue paper

a tissue paper and web technology, applied in the direction of non-fibrous pulp addition, pulp liquor regeneration, inorganic base addition, etc., can solve the problems of tissue paper being difficult to dewater during its production, too low dryness during production, and mechanically produced fibrous materials find only limited use, etc., to achieve improved utilization of organic materials, use extraordinarily efficiently, and less chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

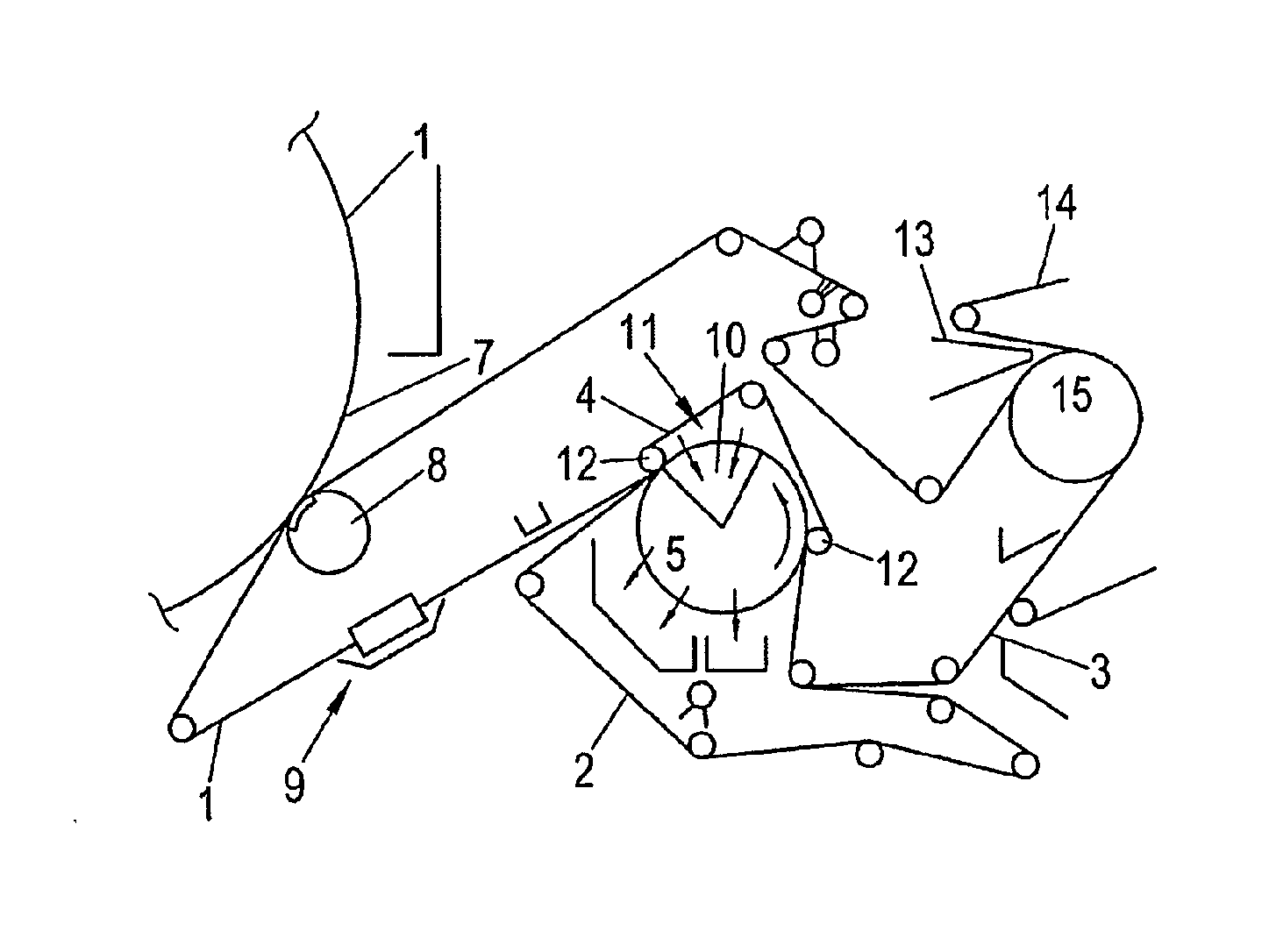

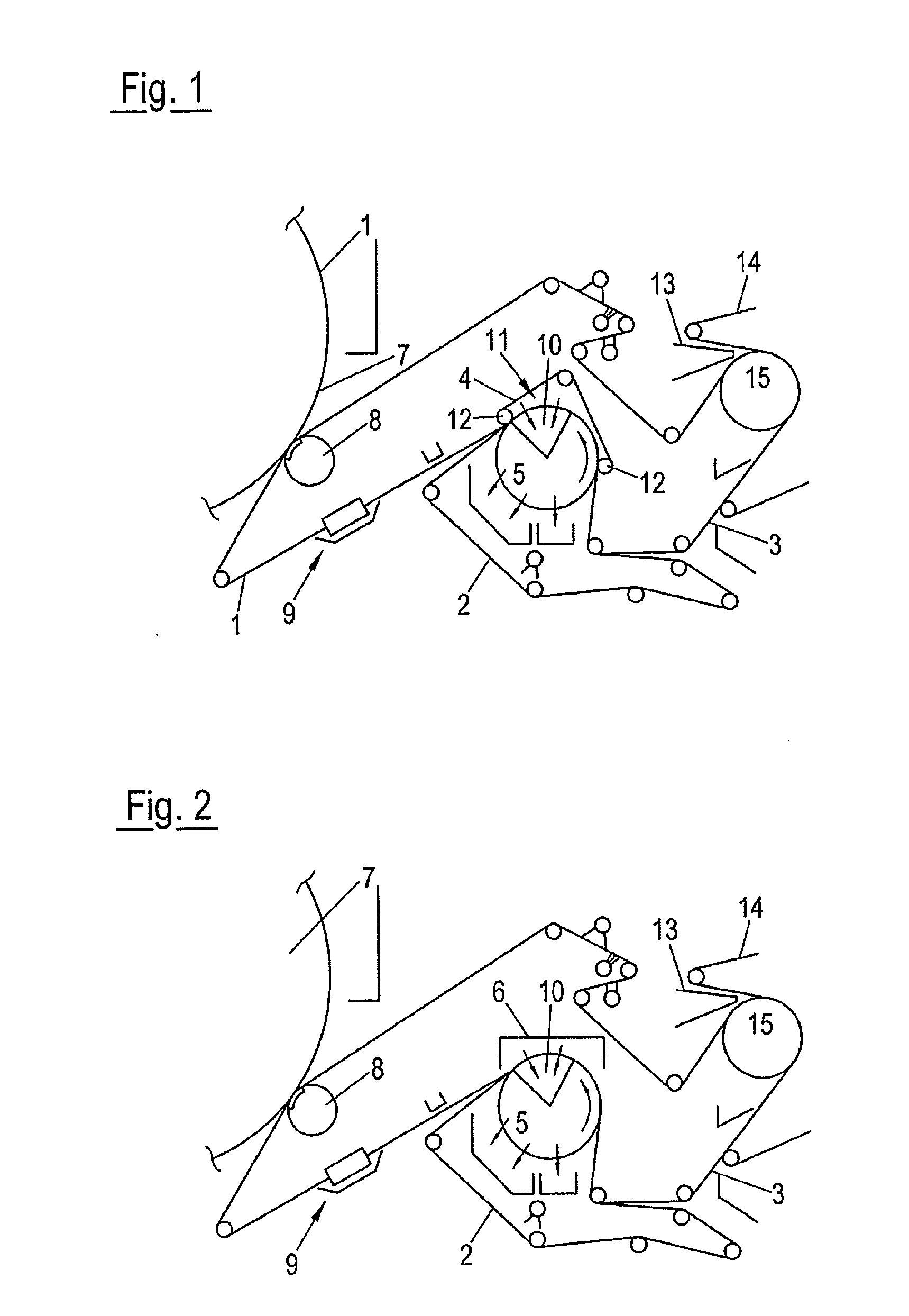

Image

Examples

example 1

Coniferous Wood Digestion in the Liquid Phase

[0099]A mixture of birch wood and Douglas fir chips, after steaming (30 minutes in saturated steam at 105° C.), was dosed with a sodium sulfite digestion solution with a liquor ratio of wood:digestion solution of 1:3. The total use of chemicals was less than 15%, based on o.d. wood. The pH at the start of the digestion was adjusted to pH 8.5-9 by adding SO2.

[0100]The birch wood / chips mixture impregnated with chemical solution was heated to 170° C. over a time period of 90 minutes and digested at this maximum temperature over 60 minutes.

[0101]The free-flowing liquid was then removed by centrifuging, collected and analyzed and strengthened in an arrangement for feeding back unused liquid and in this way conditioned for the next digestion.

[0102]The digested chips were defibered. Partial quantities of the fibrous material produced in this way were refined for different times in order to determine the strength at different freenesses. The expe...

example 2

[0109]The fibrous material was produced from birch chips, the pH at the start of the digestion being 9.4.

[0110]In addition to the 15% total chemicals (sulfite and NaOH in the prescribed ratio), 0.1% anthraquinone, based on the quantity of wood used, was added.

[0111]The digestion time was 60 minutes.

[0112]The following values resulted:

Yield (%):81.1Lignin content:22.7Whiteness (% ISO):53.7Tearing length (km):9.6Tear propagation resistance (cN; 100 g / m2):75.0

[0113]As a result of the addition of 0.1% anthraquinone, the digestion time can be reduced from about 180 minutes to 60 minutes under otherwise unchanged digestion conditions. This time gain is valuable, above all because the fibrous material production plants can be dimensioned smaller. Further potential savings reside in the fact that the temperature needed for the digestion has to be maintained over only a very much shorter time period.

[0114]Furthermore, it was determined that, with a decreasing use of overall chemicals to valu...

example 3

Deciduous Wood Digestion in the Liquid Phase

[0115]Eucalyptus chips, after steaming, have a sodium sulfite digestion solution added at a liquor ratio of wood:digestion solution of 1:3. The use of chemicals was 10.5% here (as NaOH) on o.d. chips.

[0116]Over a time period of 90 minutes, the material to be digested was impregnated and the digestion material was heated to the maximum digestion temperature of 170° C. The digestion time was 50 minutes.

[0117]Digestions with eucalyptus wood show that these materials can be produced with a specific energy input for defibering of less than 250 kWh / t.

[0118]The yield in these trials was around 77%, based on the wood mass used. Given an initial freeness of 14°SR, these materials already have a 3.5 km tearing length with a specific weight of 2.05 cm3 / g. In the subsequent bleaching these materials could be bleached to whitenesses of 79.9% ISO.

[0119]Trials have shown that the digestions in the vapor phase exhibit a lower overall time requirement. As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tearing length | aaaaa | aaaaa |

| tearing length | aaaaa | aaaaa |

| tearing length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com