Method for producing flavored particulate solid dispersions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0058]Experiments to date have demonstrated a high capacity for waxes to absorb and disperse methyl salicylate (e.g., as much as 15% in paraffin). In addition, methyl salicylate-loaded wax particles have been produced by dispersion of a molten wax-methyl salicylate solution in hot aqueous ethanol with rapid agitation and cooling.

[0059]The evaluation of a series of GRAS materials for use as sustained-release methyl salicylate matrices has led to the selection of cetyl alcohol and PEG 8000 as promising candidates. Cetyl alcohol affords steady, reproducible yet delayed methyl salicylate release in artificial saliva. PEG 8000-methyl salicylate dispersions lead to a burst of methyl salicylate, with a more delayed release when dispersed in tobacco.

[0060]Self-emulsified cetyl alcohol particles prepared from aqueous emulsions also give relatively steady, sustained delivery. Flavored cetyl alcohol particles, combined with neat methyl salicylate dispersed in tobacco, offer another alternative...

example 2

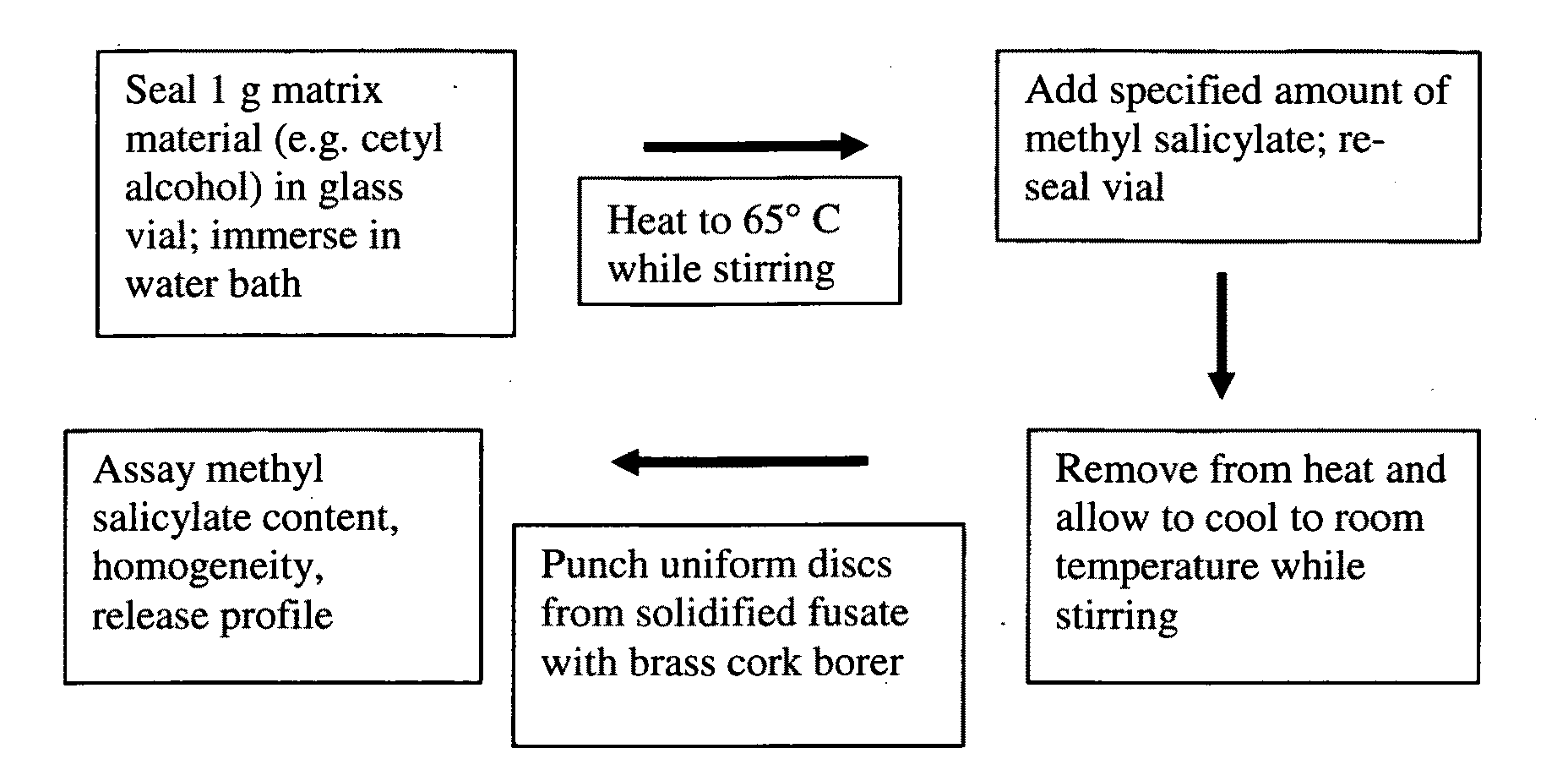

[0074]Individual flavor reservoirs or some other type of ‘flavor-pak’ might be included in a snuff can or in a snuff pouch for sustained flavor release. Alternatively, snuff might be incorporated directly into such a flavored matrix in order to make a buccal pellet. Such a reservoir or pellet might be comprised of a tablet, a punch or some other flavor-matrix mass. Accordingly, an initial evaluation of the release characteristics of methyl salicylate from the solid dispersions was performed using fused punches. These punches, rather similar to a tablet, were prepared by removing a uniform, 6 mm diameter disc from a 2 mm thick solid dispersion produced as described in the scheme of FIG. 1. The punches, uniform in size and surface area, were homogeneous in methyl salicylate content (20% w / w). Normalized for weight, the punches were placed in a 20 mL glass vial, and 10 mL artificial saliva (see p. 30, para. 3; Na et al.) was gently added with slow stirring at 37° C. At the indicated ti...

example 3

[0077]As stated, the punches described in the previous Example afford both an initial assessment of methyl salicylate release from the various matrix materials, as well as a proof of concept model for flavor release from an individual reservoir. Flavor-loaded matrix particles, which might be dispersed into loose, tinned snuff, offer another option for sustained-release delivery. Size, color and texture could be optimized for flavor delivery and consumer acceptance. The larger surface area-to-volume ratio of particles may offer more rapid flavor release. In addition, several methods are available for the production of such particles, including comminution of a solid dispersion, spraying molten solutions and various emulsion technologies.

[0078]A series of methyl salicylate particles were produced by grinding the cooled solid dispersions previously described in a glass mortar and pestle, then passing the particles through standard testing sieves. Light microscopy revealed that the part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com