Double-masking technique for increasing fabrication yield in superconducting electronics

a superconducting electronic and double-masking technology, applied in the direction of superconductor details, superconductor devices, dissimilar materials junction devices, etc., can solve the problems of major fabrication defects, improve ic yield, improve reliability and ic yield, the effect of increasing the number of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

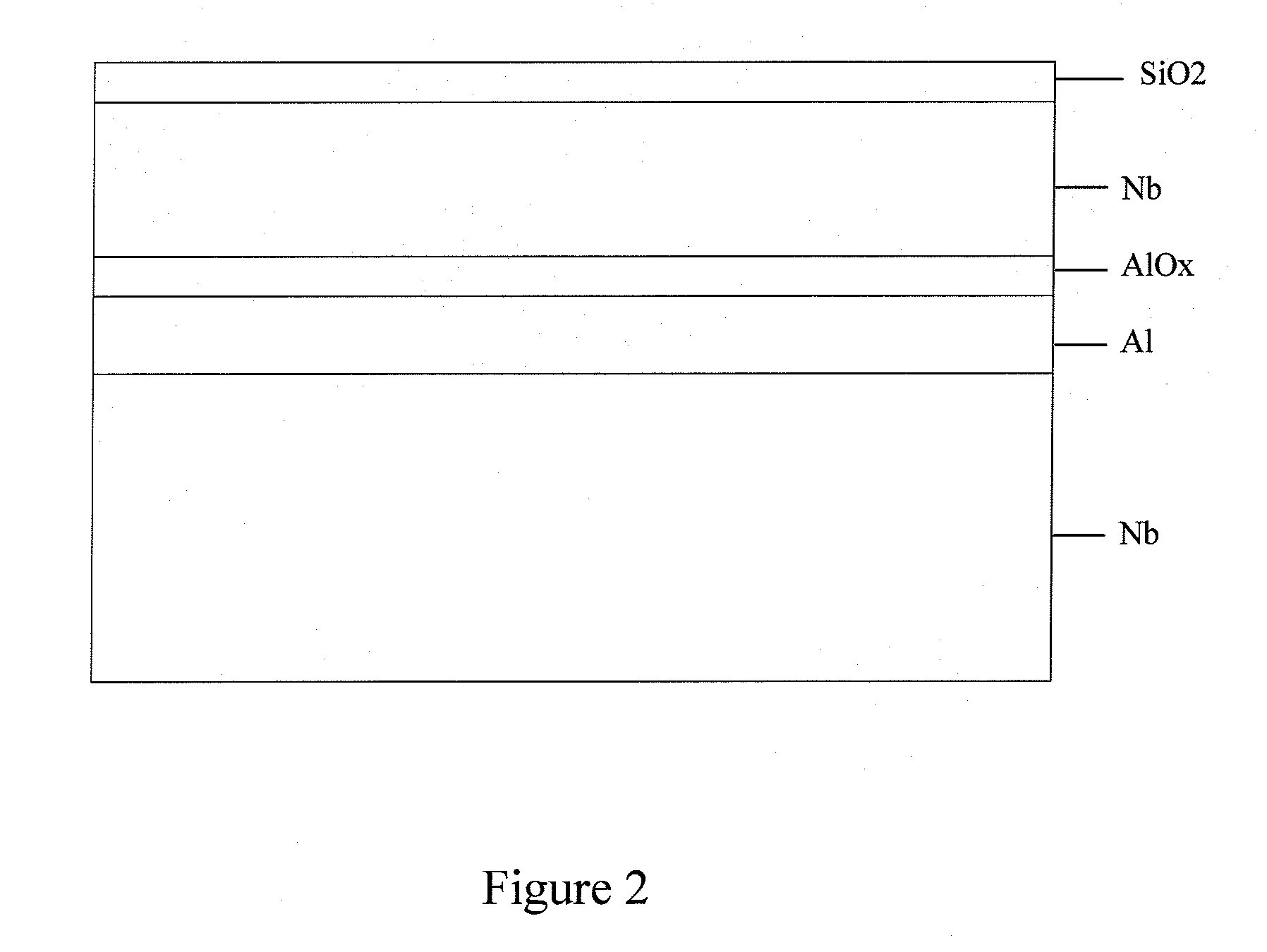

[0033]A new fabrication method is proposed for increasing the yield and quality of superconducting junctions and more particularly Josephson junctions and Josephson-based digital and analog circuits in superconducting electronics. The method is based on using a double-layer mask for partial anodization of the junction side-walls and base-electrode around the junction. The top layer of this mask is a photoresist or electron-beam resist, and the bottom layer is a dielectric (e.g., SiO2) that is insoluble in either aqueous or organic solvents. A more detailed description will now be given.

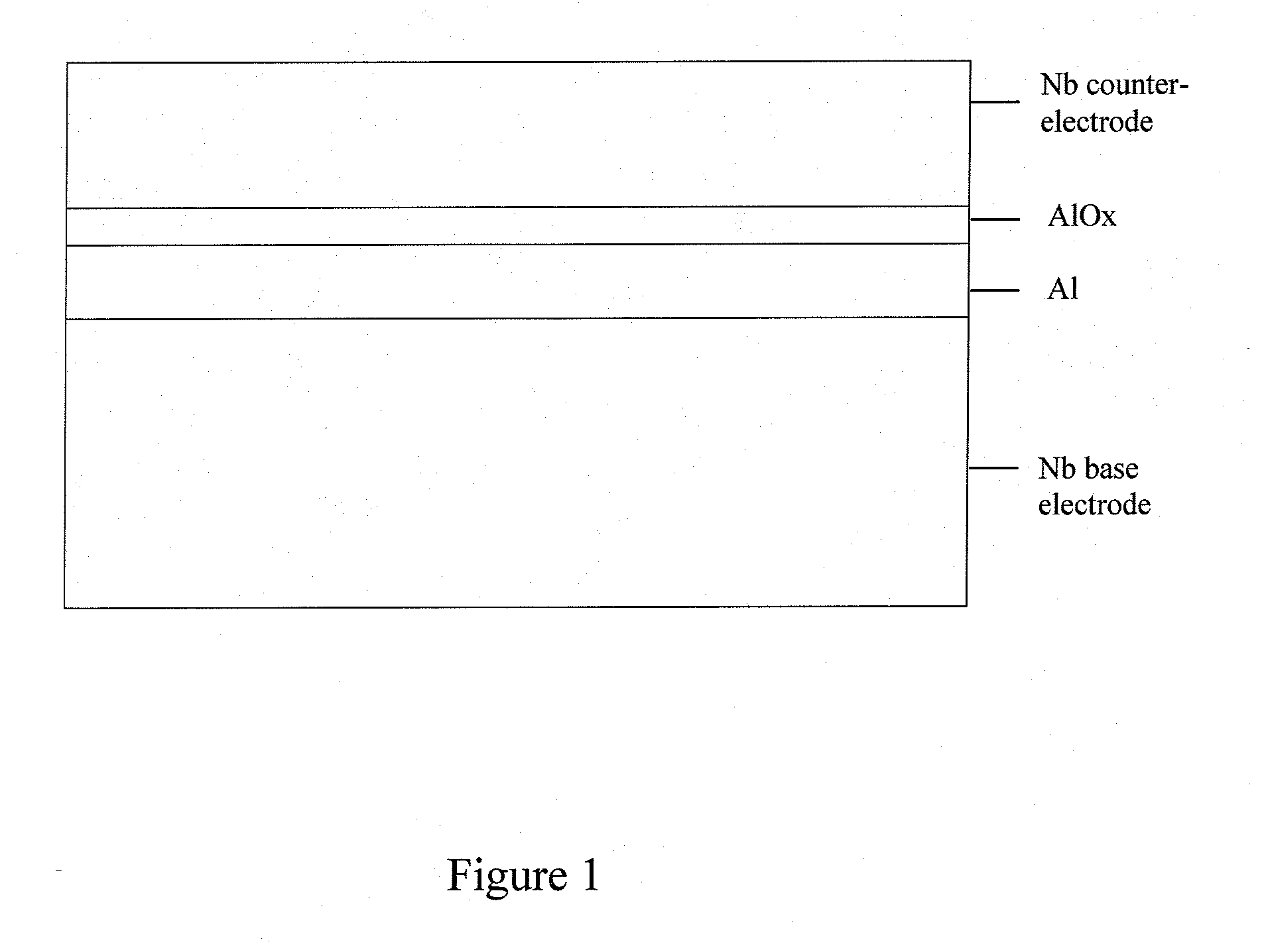

[0034]The existing fabrication scheme for making Nb-based Josephson tunnel junctions for superconducting electronics is comprised of the following fabrication steps:

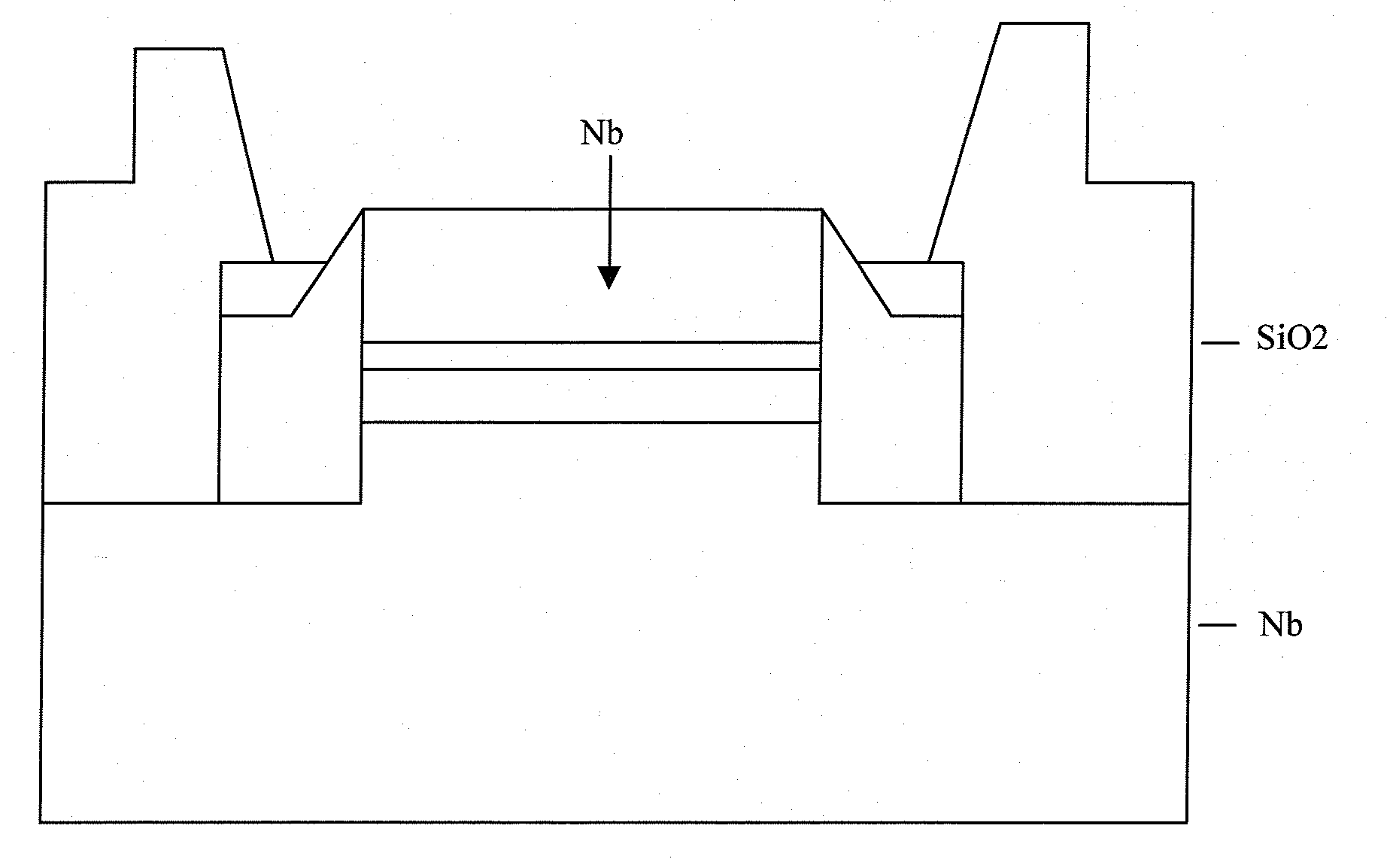

[0035]1. As shown in FIG. 1, a Nb / Al / AlOx / Nb trilayer is deposited in-situ on a wafer that includes or will include several other patterned layers of metal and dielectric. A tunnel barrier is formed by in-situ thermal oxidation of the Al l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com