Plasma processing apparatus

a processing apparatus and plasma technology, applied in the direction of electrical apparatus, basic electric elements, electric discharge tubes, etc., can solve the problems of difficult to maintain the long-term stability and processing properties of the wafer edge portion, and the required processing accuracy is difficult to maintain. maintain the processing properties, suppress the time-based change, and minimize the influence of tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

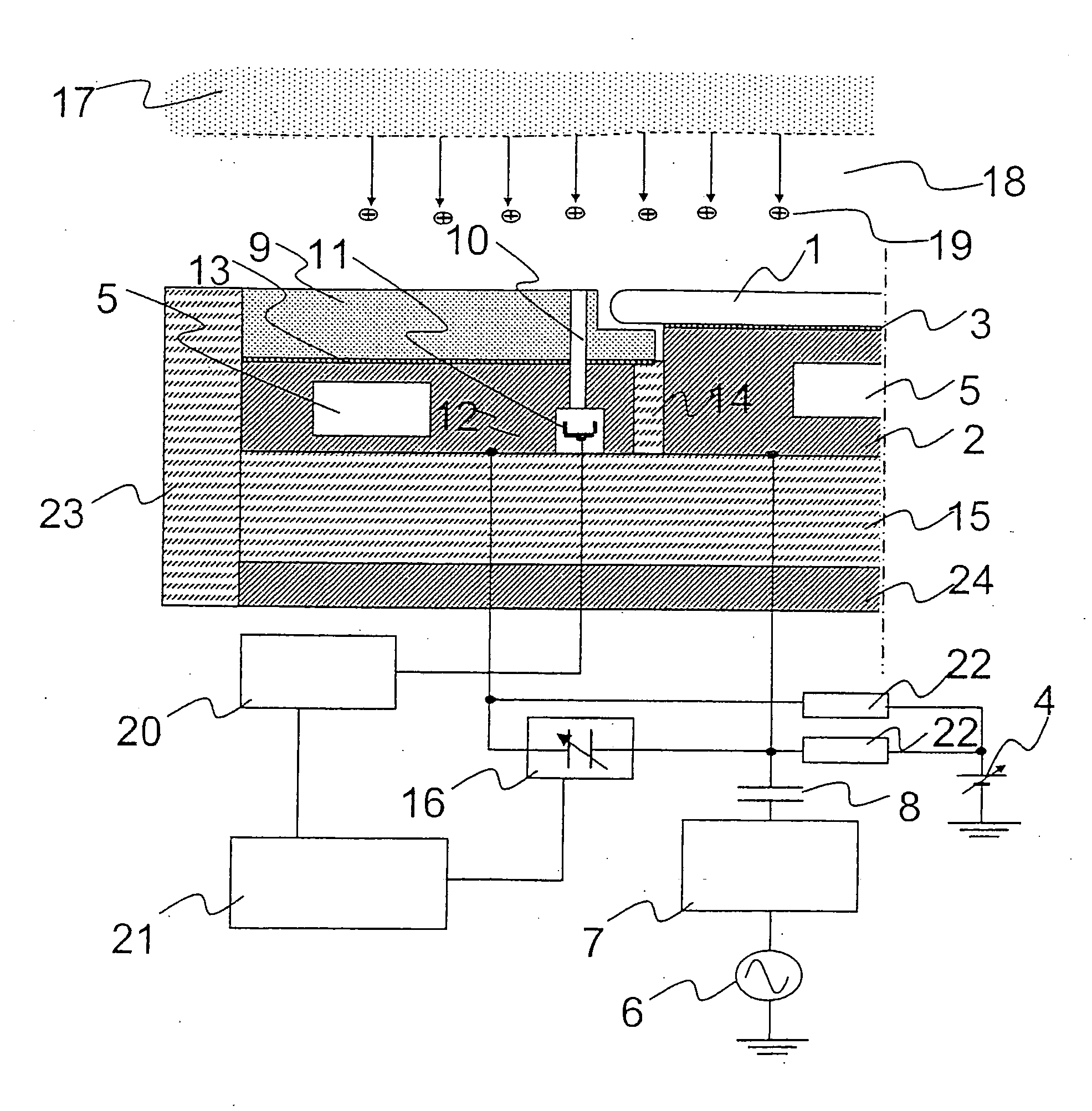

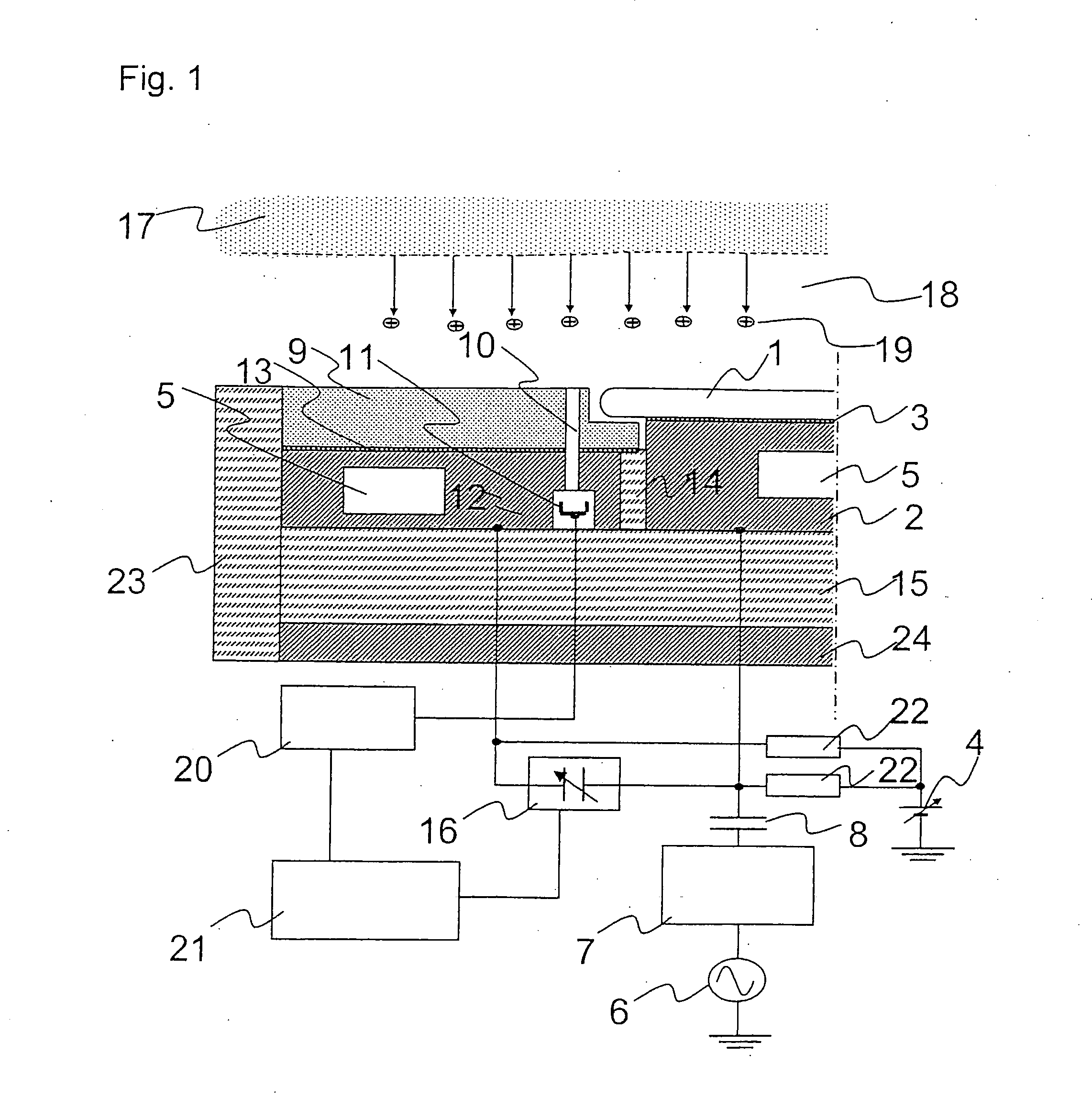

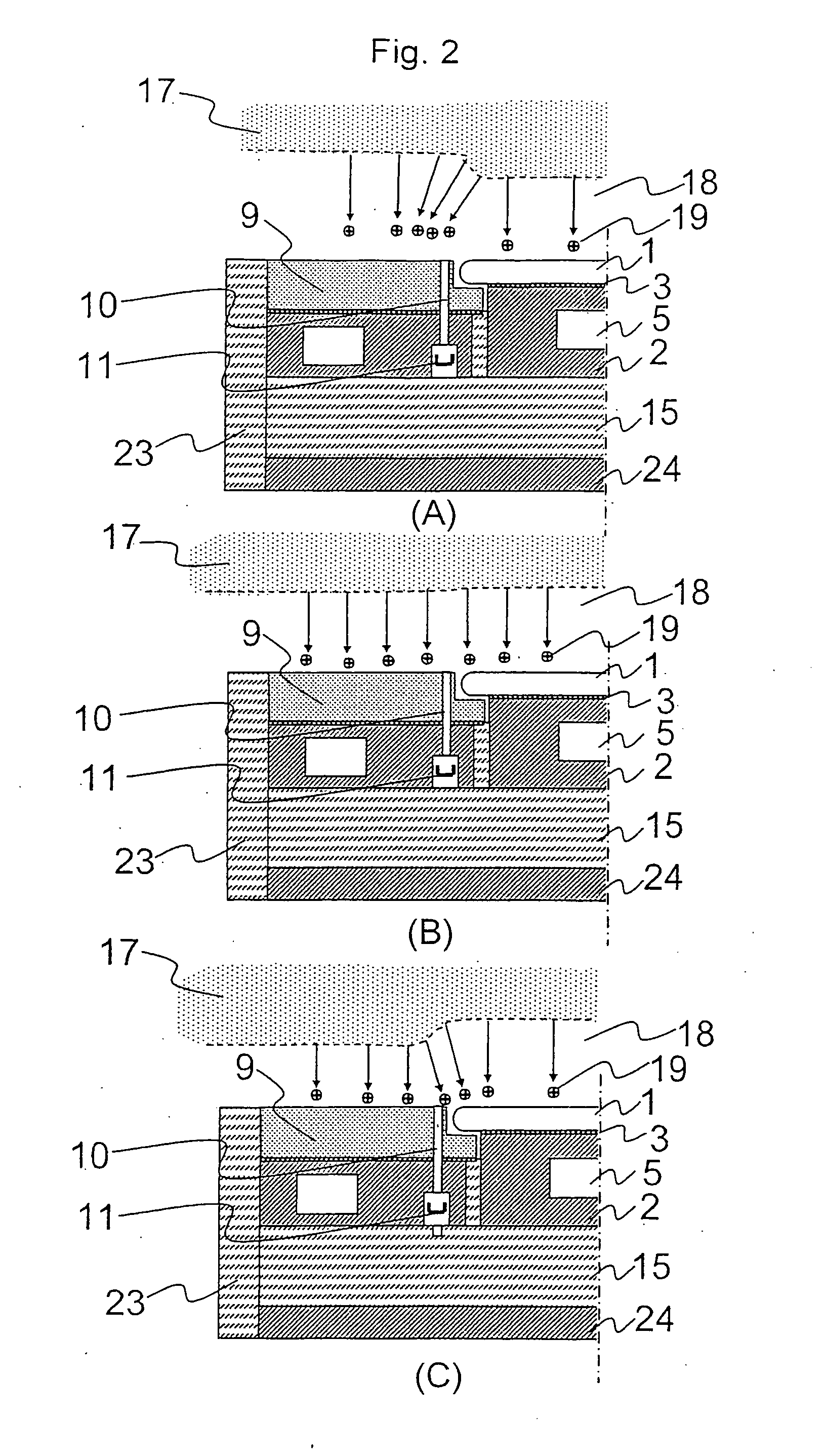

[0018]A first embodiment according to the present invention will be described with reference to FIG. 1. FIG. 1 is an enlarged view of a wafer end portion of a lower electrode 2 in a plasma processing apparatus, on which lower electrode a silicon wafer 1 as a sample to be processed is mounted. In the plasma processing apparatus according to the present invention, the silicon wafer 1 is attracted to the lower electrode 2 via an insulating film for electrostatic chuck 3. Further, the electrostatic chuck force is controlled by a DC power source 4. The lower electrode 2 is cooled by a liquid or gas refrigerant which is made to flow through a refrigerant passage 5. A high-frequency voltage for drawing ions to the wafer is supplied to the lower electrode 2 from a high-frequency power supply 6 via a matching circuit 7 and a blocking capacitor 8.

[0019]At the periphery of the silicon wafer 1, an annular conductor member, for example, a focus ring 9 made of silicon is arranged concentrically w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com