Antiwear hydraulic fluid composition with useful emulsifying and rust prevention properties

a technology of hydraulic fluid and anti-wear, applied in the field of anti-wear hydraulic fluid composition, can solve problems such as poor lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0040]An antiwear hydraulic fluid composition was prepared consisting of the baseline formulation above with the addition of 0.225 wt. % of an overbased calcium alkyl-substituted hydroxybenzoate detergent wherein at least 90% of the alkyl groups are C20 or greater and 0.06 wt. % of the succinate ester dispersant. The overbased calcium alkyl-substituted hydroxybenzoate detergent was prepared according to the method described in Example 1 of US Patent Application 2007 / 0027043 and has a calcium content of 5.35 wt. %, a TBN of 150 and a CI of 56.

example 2

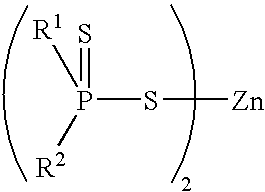

[0041]An antiwear hydraulic fluid composition was prepared in accordance with the formulation of Example 1 except that 0.01 wt. % of a linear alcohol ethoxylate emulsifier and 0.16 wt % zinc dialkyl dithiophosphate was added.

example 3

[0049]An antiwear hydraulic fluid composition was prepared consisting of the baseline formulation above with the addition of 0.075 wt. % of the 56 CI overbased calcium alkyl-substituted hydroxybenzoate detergent as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| lubricating viscosity | aaaaa | aaaaa |

| total weight | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com