Tri-color white light LED lamp

a white light led lamp and tri-color technology, applied in the field of tri-color lamps, can solve the problems of low lifetime, low efficiency, and reduced led efficiency, and achieve the effect of high efficiency and high quenching temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of (Ba0.49Sr0.49)2SiO4:Eu0.02

[0058]15.00 9 (76.01 mmol) BaCO3, 11.22 (76.01 mmol) SrCO3, 0.546 (1.55 mmol) EU203, and 4.80 9 (79.90 mmol) SiO2 are suspended in ethanol. The solvent is slowly evaporated under stirring and NH4Cl is subsequently added to the dried powder. After the material has been thoroughly ground in an agate mortar, the material is filled into alumina crucibles and fired at 600° C. for 0.5 h. The powder is ground again and the obtained powder is annealed at 1100 to 1200° C. for 4 h under N2 / H2. Cooling down to room temperature occurs under N2 / H2. Finally, the powder is milled and sieved through a 36 μm sieve.

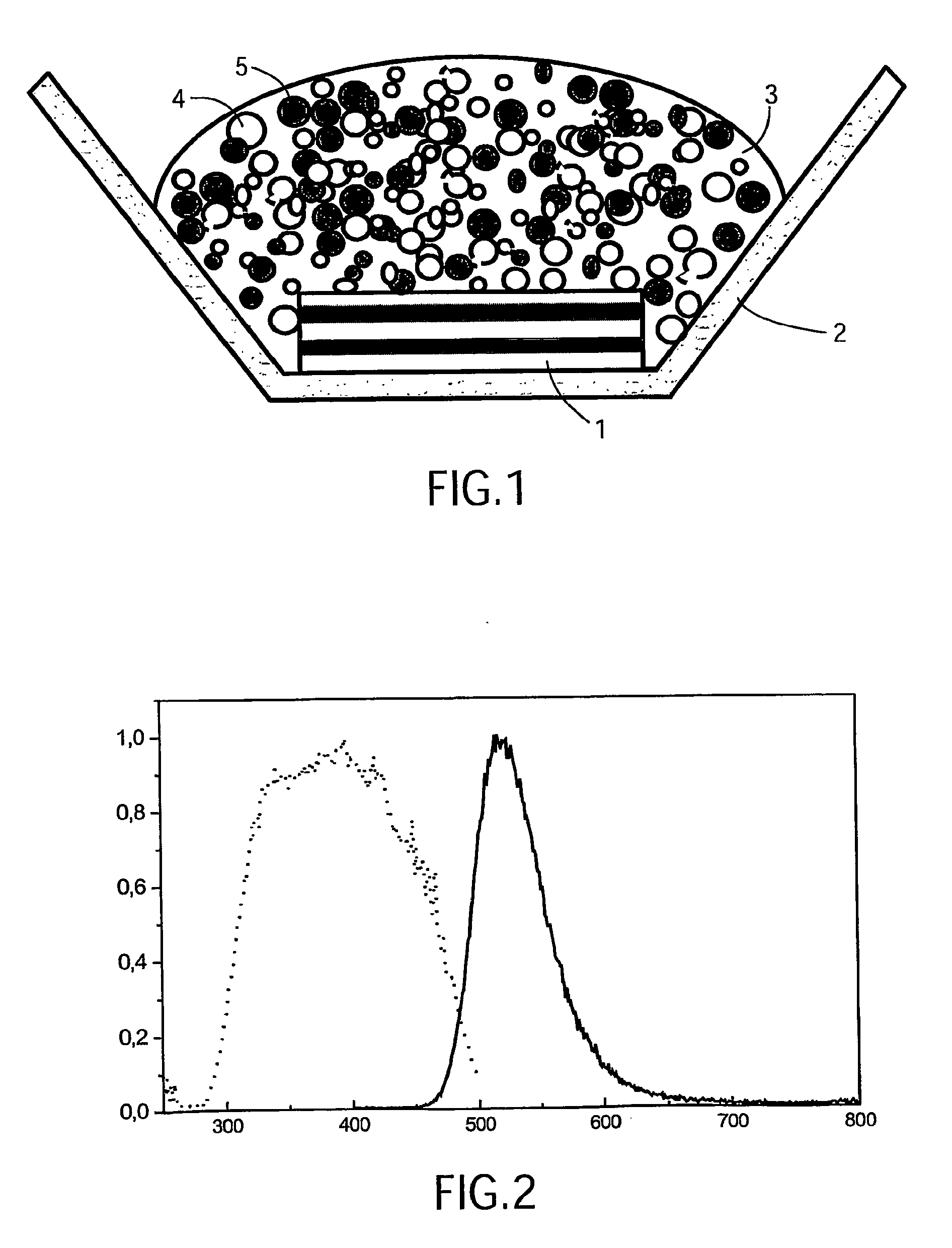

[0059]The spectroscopic properties of (Ba0.49Sr0.49)2SiO4:Eu0.02, prepared this way, are: QE460nm of 70%, Abs460nm of 80%, LE of 483 [lm / W] and colour point x=0.24, y=0.65.

example 2

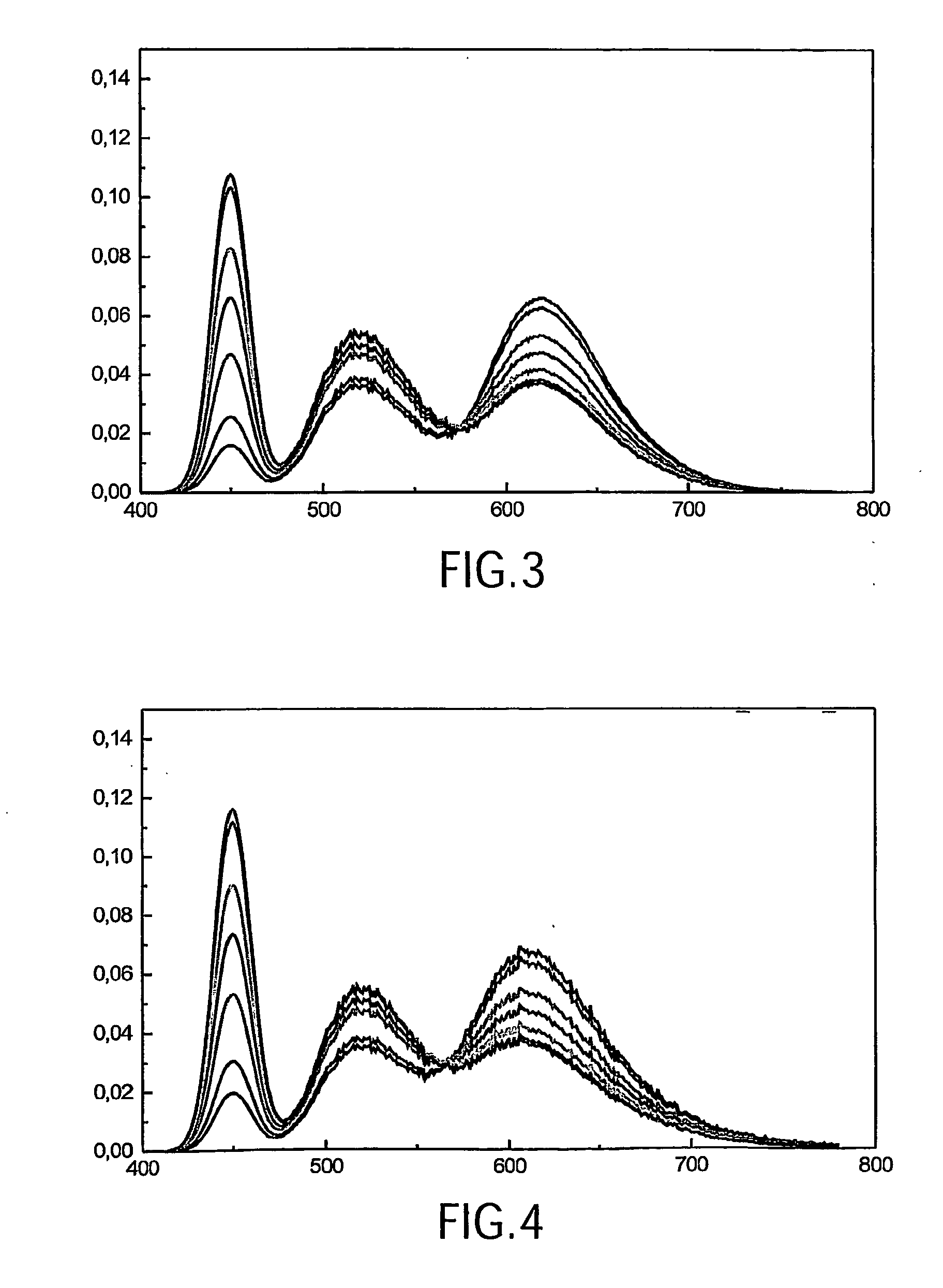

White LED Comprising (Ba0.49Sr0.49)2SiO4:Eu0.02 and Sr2Si5N8:Eu

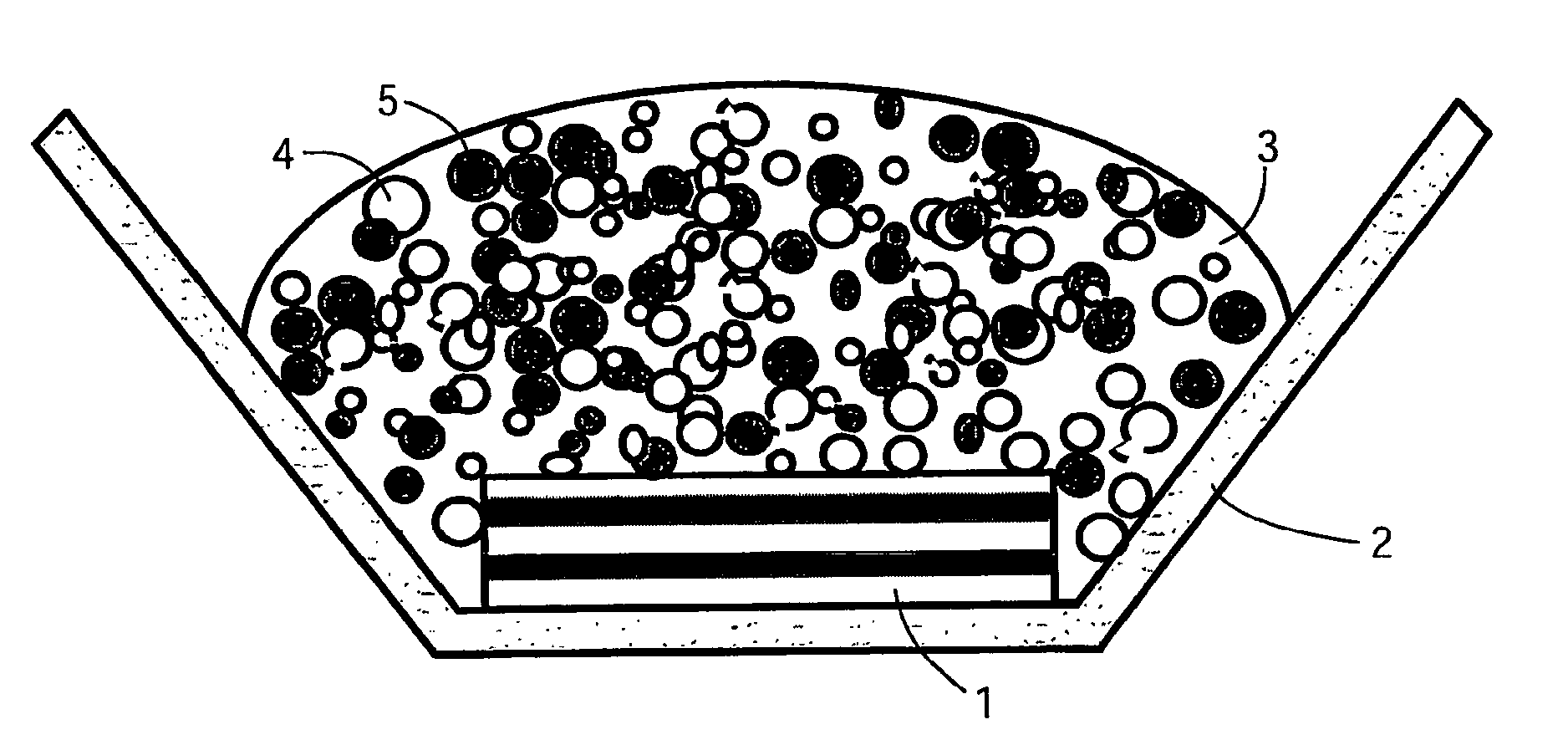

[0060]A phosphor blend comprising (Ba0.49Sr0.49)2SiO4:Eu0.02 and Sr2Si5N8:Eu is suspended in silicone monomer oil and a droplet of the suspension is deposited onto an InGaN die. A catalyst is added to the silicone monomer to start the polymerization process, resulting in hardening of the silicone. Finally, the LED is sealed with a plastic cap.

example 3

White LED Comprising (Ba0.49Sr0.49)2SiO4:Eu0.02 and SrS:Eu

[0061]A phosphor blend comprising (Ba0.49Sr0.49)2SiO4:Eu0.02 and SrS:Eu is suspended in silicone monomer oil and a droplet of the suspension is deposited onto an InGaN die. A catalyst is added to the silicone monomer to start the polymerization process, resulting in hardening of the silicone. Finally, the LED is sealed with a plastic cap.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| quenching temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com