Fine fibrous cellulosic material and process for producing the same

a cellulosic material and fibrous technology, applied in the direction of glucose production, transportation and packaging, multi-stage pulping process, etc., can solve the problems of insufficient yield of saccharides and inability to undo lignin-hemicellulose entanglement, so as to improve the hydrolysis rate and yield of saccharines , the effect of improving the yield of saccharines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

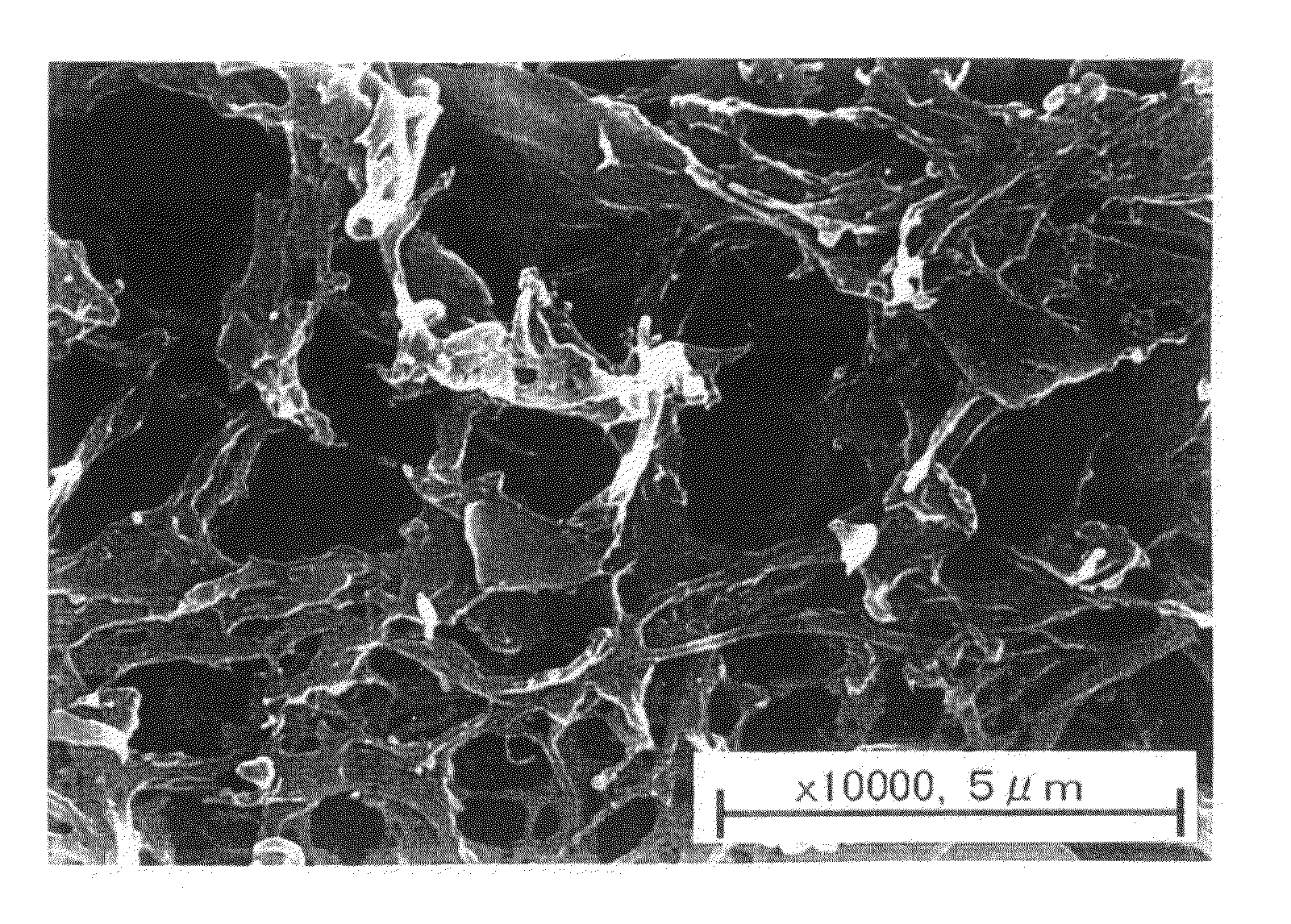

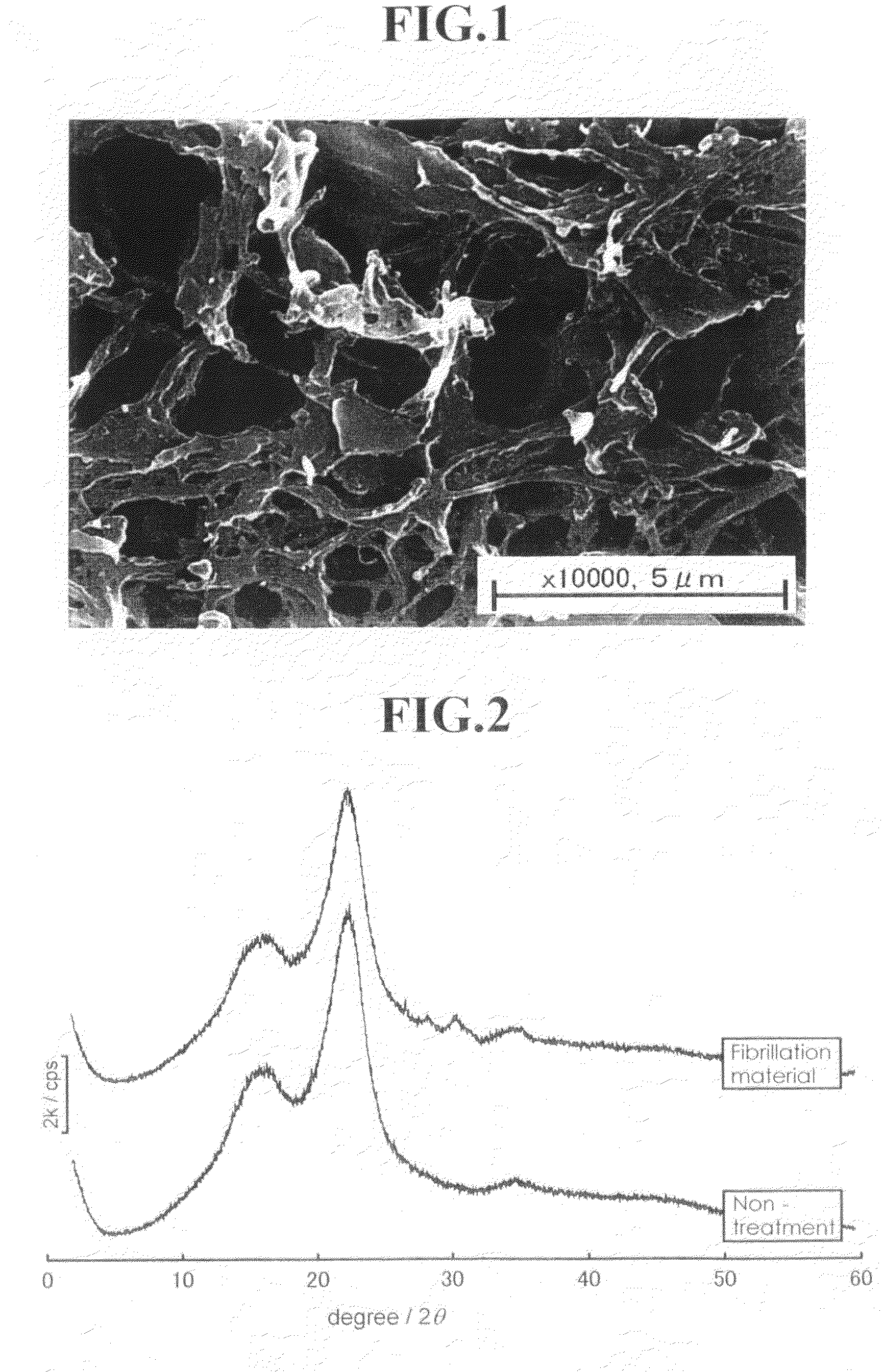

[0192]An example using a eucalyptus which is a broad-leaved tree as a raw material for a cellulosic material and a planetary ball mill for mechanical pulverization is shown.

[0193]The rough pulverization of eucalyptus chips for making paper used as the eucalyptus was performed to make 0.2 mm-pass eucalyptus wood flour by a cutter mill. The resultant eucalyptus wood flour (20 g) was charged into a planetary ball mill pot made of zirconia (internal capacity: 500 ml; P-5 type; manufactured by Fritsch Corporation (Germany)), and 25 zirconia balls having a diameter of 20 mm were filled thereinto.

[0194]Subsequently, 200 ml of water (fibrillation material) was added as a medium (eucalyptus wood flour in ten times the amount of water), and a lid was put on the planetary ball mill pot made of zirconia. In ball mill treatment, a cycle of treatment at an autorotation speed of 120 rpm for 20 minutes and stop for 10 minutes was repeated 100 times, and mechanical pulverization (hereinafter also re...

example 2

[0196]A sample 2 (fine fibrous cellulosic material; average width of 0.04 μm and average length of 7 μm) was obtained by the same method as in Example 1 except that eucalyptus wood flour was 13.5 g. The amount of water was 15 times that of the eucalyptus wood flour. As a result of fibrillation treatment, the obtained mixture had low viscosity and was brown and slurry.

example 3

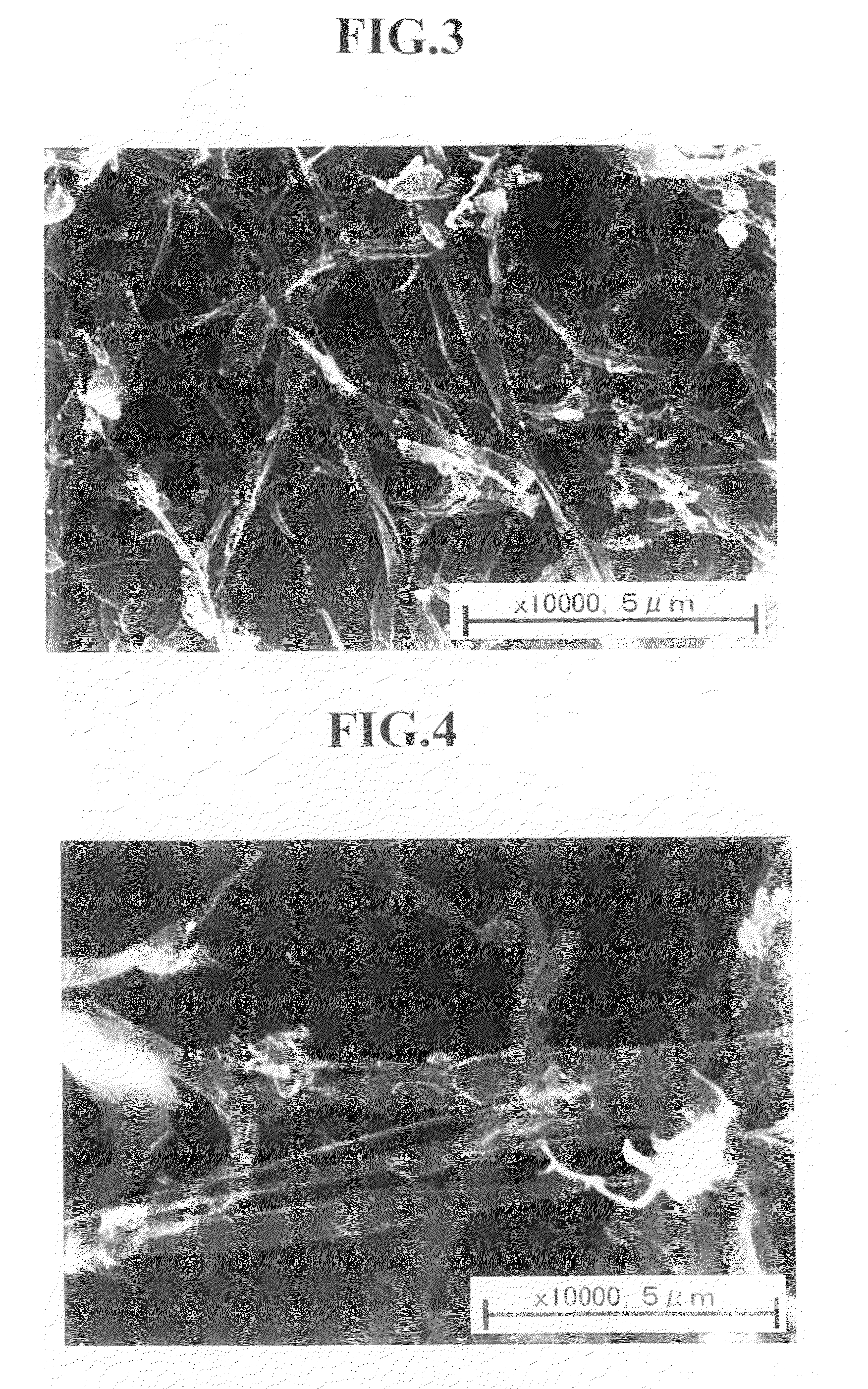

[0216]An example of using chips for making paper, of Oregon pine which is an acicular tree, as a raw material for a cellulosic material, and using a planetary ball mill for mechanical pulverization is shown.

[0217]The rough pulverization of the Oregon pine chips for making paper was performed to make 0.2 mm-pass Oregon pine wood flour by a cutter mill. The resultant Oregon pine wood flour (2.3 g) was charged into a planetary ball mill pot made of zirconia (internal capacity: 45 ml; P-7 type; manufactured by Fritsch Corporation (Germany)), and seven zirconia balls having a diameter of 10 mm were filled thereinto.

[0218]Subsequently, 23 ml of water (fibrillation material) was added as a medium (Oregon pine wood flour in ten times the amount of water), and a lid was put on the planetary ball mill pot made of zirconia. In ball mill treatment, a cycle of treatment at an autorotation speed of 200 rpm for 20 minutes and stop for 10 minutes was repeated 100 times, and fibrillation treatment w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com