Apparatus for Charging Dry Air or Nitrogen Gas into a Container for Storing Semiconductor Wafers and an Apparatus for Thereby Removing Static Electricity from the Wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

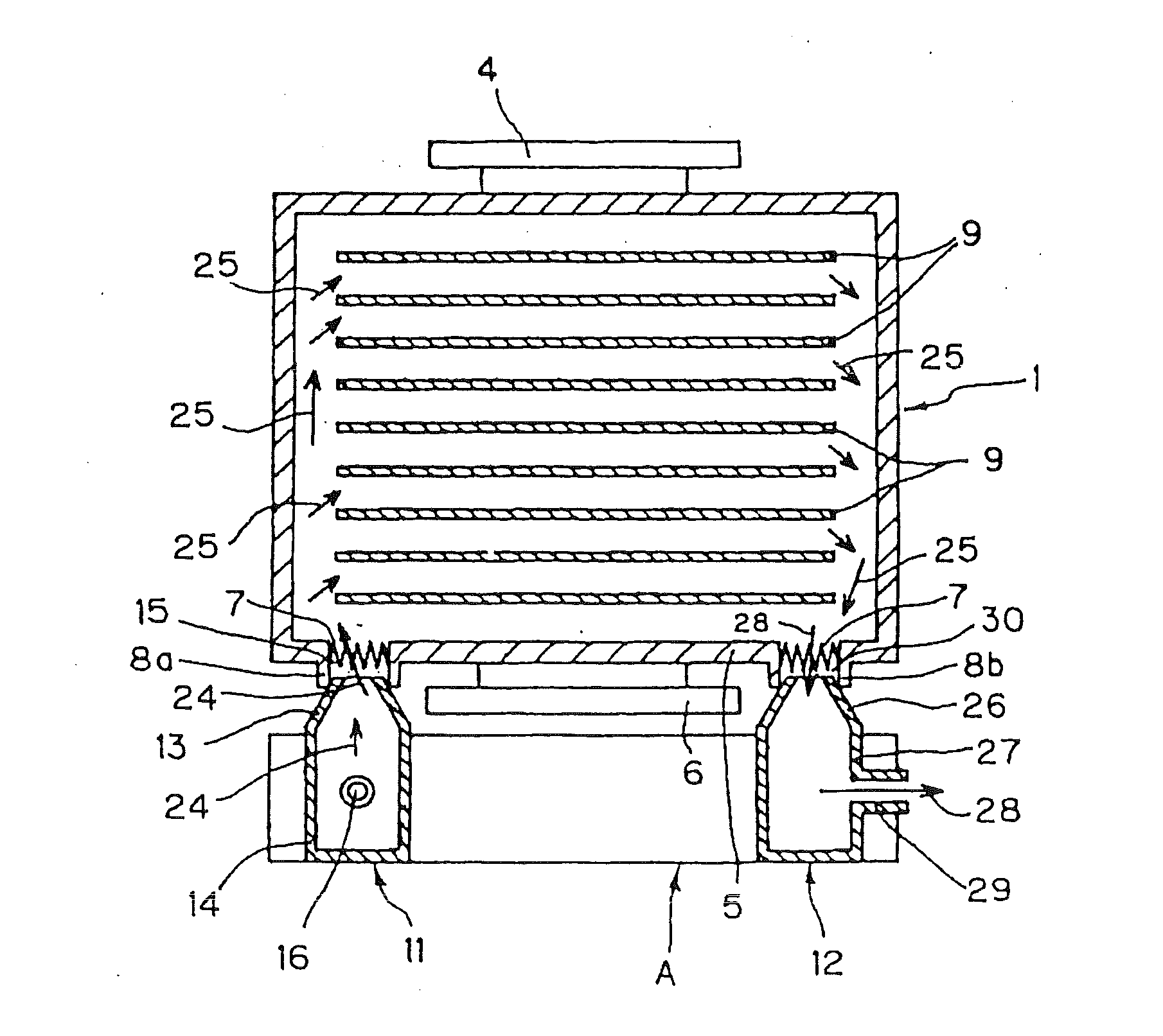

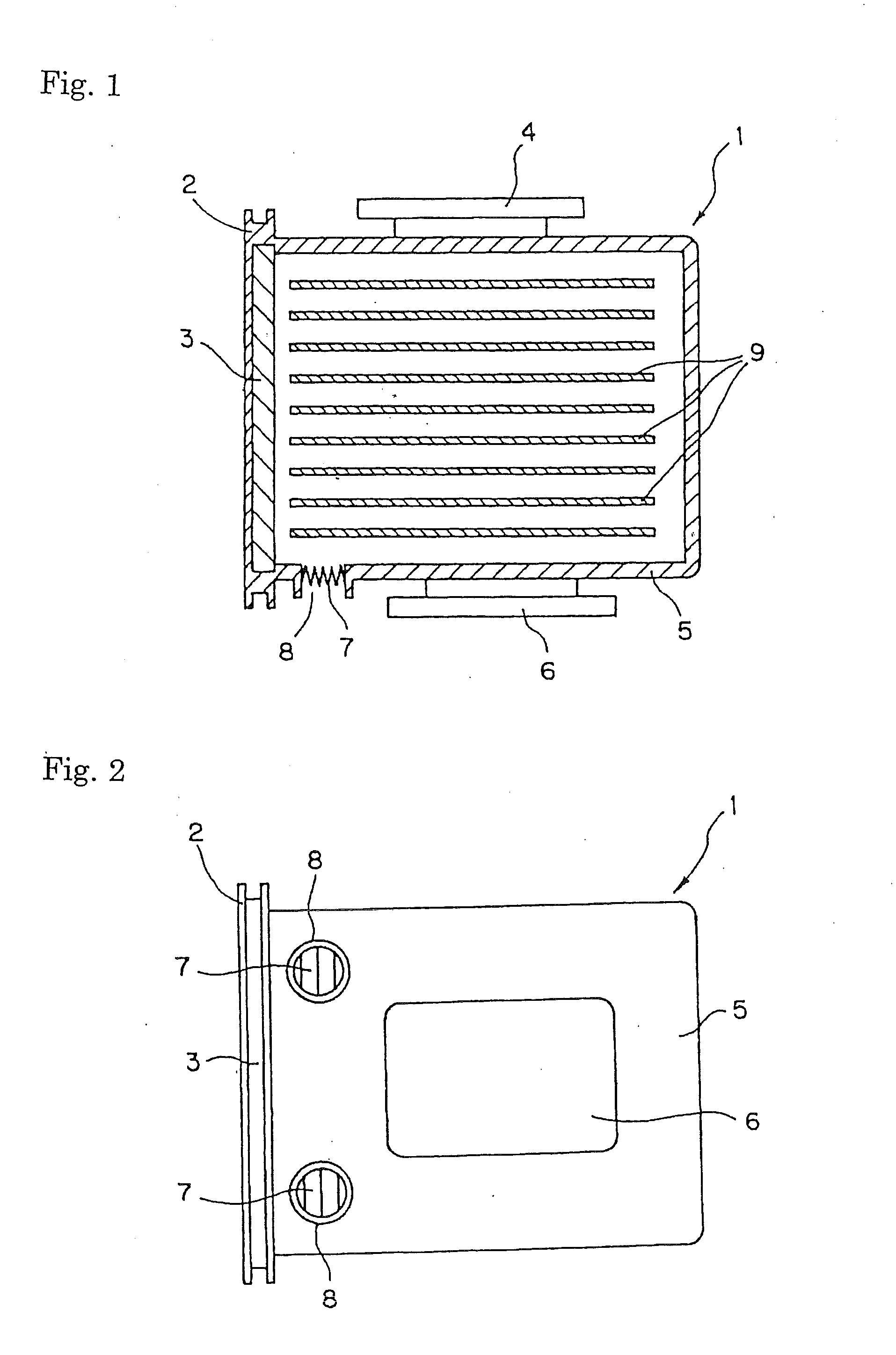

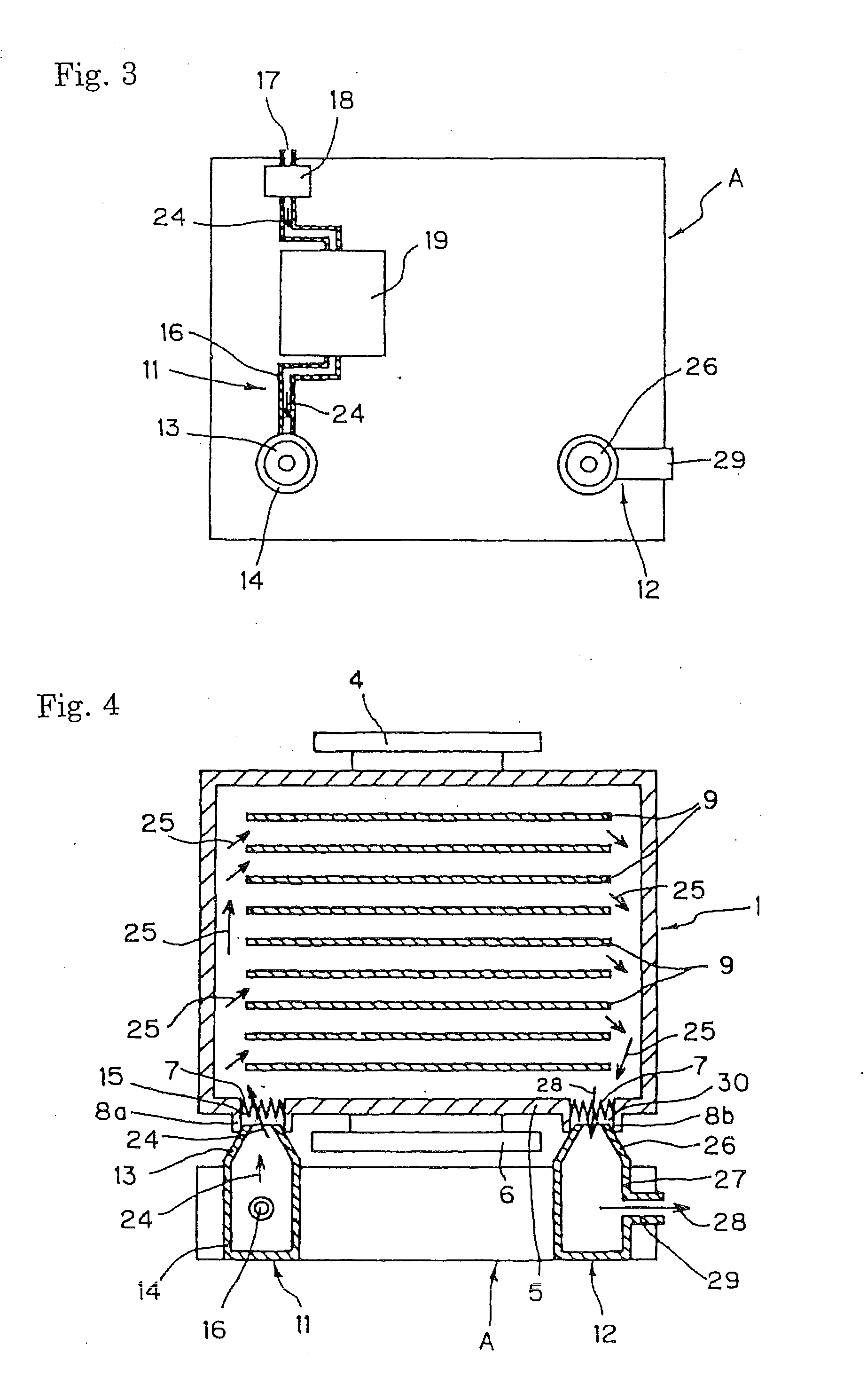

[0077]Embodiment 1 of the present inventions, the apparatus for charging dry air or nitrogen gas, is now explained in detail based on the figures. FIG. 1 shows a vertical and sectional view of the container for storing semiconductor wafers that is used for the present inventions. FIG. 2 shows a bottom plane view of the container. As shown in FIGS. 1 and 2, the container 1 for storing semiconductor wafers comprises an openable and closable lid 3 that is disposed at the front of the container. and the container 1 has a flange 2, a hook 4, for being suspended, disposed at its top plate, a leg 6 for being mounted on the table (not shown) disposed at its bottom plate 5, and a plurality of openings 8 having a PTFE filter 7.

[0078]The semiconductor wafers 9 are stored in the container 1. Except when the wafers 9 are being processed in an apparatus (not shown), since the wafers 9 are stored in the container 1, chemical gas is prevented from contacting the surfaces of the wafers 9.

[0079]FIG. ...

embodiment 2

[0094]As Embodiment 2, an apparatus for removing static electricity using the above apparatus for charging dry air or nitrogen gas, is below explained based on the figures.

[0095]FIG. 8 shows a plane view of the apparatus for removing static electricity using the apparatus for charging dry air or nitrogen gas, of this invention. FIG. 9 shows a vertical and sectional view of the apparatus for removing static electricity that is attached to the container for storing the semiconductor wafers, which is shown by FIGS. 1 and 2. As shown in FIGS. 8 and 9, the apparatus B for removing static electricity, which is used for removing the static electricity charged on the wafers 9 in the container 1, comprises:

[0096]a portion 11a for providing ionized dry air or nitrogen gas to charge the ionized dry air or nitrogen gas into the container 1, which portion 11a uses a portion 11 for providing the dry air or nitrogen gas of the apparatus A,

[0097]a portion 12a for exhausting the used ionized dry air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com