Colored curable composition, color filter, and method for producing color filter

a color curable and composition technology, applied in the field of color curable composition, color filter, and method for producing color filter, can solve problems such as fastness problems of dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

1-1. Preparation of Green Pigment Dispersion Liquid

[0232]—Preparation of green pigment dispersion liquid P1—

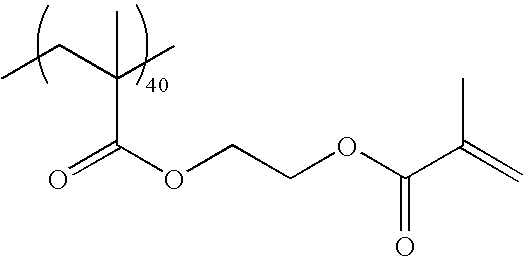

[0233]A mixed liquid containing 12.6 parts of a pigment mixture of C. I. Pigment Green 58 and C. I. Pigment Yellow 139 (mixed in a mass ratio of 100 / 55), 5.2 parts of a dispersant DISPERBYK 2001 (trade name, manufactured by BYK-Chemie (BYK), solid content 45.1% by mass), 2.7 parts of a dispersing resin P-1, and 78.3 parts of propylene glycol monomethyl ether acetate as a solvent was stirred and dispersed in a bead mill for 15 hours, thereby preparing a green pigment dispersion liquid.

1-2. Preparation of Red Pigment Dispersion Liquid

[0234]—Preparation of Red Pigment Dispersion Liquid P2—

[0235]A mixed liquid containing 12.1 parts of a pigment mixture of C. I. Pigment Red 254 and C. I. Pigment Yellow 139 (mixed in a mass ratio of 100 / 45), 10.4 parts of a dispersant DISPERBYK 2001 (trade name, manufactured by BYK-Chemie (BYK), solid content 45.1% by mass), 3.8 parts of a dispersin...

examples 2 to 19

Comparative Example 1

[0257]Evaluations were made in the same manner as in Example 1, except that the type and proportion of pigments used for the preparation of pigment dispersion liquids, the type and amount of the epoxy compound, the type of the initiator, and the proportions of these components were changed as listed in Table 1. The addition amount change of the epoxy resin was adjusted by changing the addition amount of the alkali soluble resin. The evaluation results are shown in Table 1.

TABLE 1Yellow pigmentEpoxy compoundEvaluation resultsRatio ofAverageViscosityPigmentnumber ofPhotopolym-Poly-AlkalichangeGreen 58functionalerizationmerizablesolubleNeedleoverYPigment nametheretoCompoundgroupsContentinitiatorcompoundresinmattertimevalueExample 1Pigment Yellow 139100 / 55EHPE-3150About 155.0%OXE-01M-1 / M-305P-1A+0.361.1Example 2Pigment Yellow 139100 / 55EHPE-3150About 150.9%OXE-01M-1 / M-305P-1C+0.361.1Example 3Pigment Yellow 139100 / 55EHPE-3150About 151.0%OXE-01M-1 / M-305P-1B+0.361.1Exam...

example 20

Making of Solid-State Image Pickup Device

[0260]As described in the following example, using the method of the invention for producing a color filter, a solid-state image pickup device was made using the colored curable composition for a solid-state image pickup device.

[0261]2-1. Preparation of Resist Liquid

[0262]The following composition were mixed and dissolved to prepare a resist liquid.

[0263]

Solvent: propylene glycol monomethyl ether acetate19.20 partsSolvent: ethyl lactate36.67 partsAlkali soluble resin: 40% PGMEA solution of benzyl30.51 partsmethacrylate / methacrylic acid / 2-hydroxyethylmethacrylate copolymer (molar ratio: 60 / 22 / 18,weight average molecular weight: 15,000)Compound containing an ethylenically unsaturated12.20 partsdouble bond: dipentaerythritol hexaacrylatePolymerization inhibitor: p-methoxyphenol0.0061 parts Fluorine surfactant: F-475, manufactured by 0.83 partsDainippon Ink And Chemicals, IncorporatedPhotopolymerization initiator: trihalomethyltriazine0.586 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| average primary particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| average primary particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com