Backwash assembly and method having a rotating backwash arm for cleaning cloth filter media

a technology of cloth filter media and backwash arm, which is applied in the direction of filtration separation, sedimentation settling tank, separation process, etc., can solve the problems of poor quality effluent, chambers that had to be dewatered before maintenance could be carried out, and the filtration process at the stationary cloth media suffered a number of problems, so as to achieve high solids, high quality effluent, and high effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0110]Set forth below is a description of what is currently believed to be the preferred embodiments or best representative examples of the inventions claimed. Future and present alternatives and modifications to the preferred embodiments are contemplated. Any alternatives or modifications which make insubstantial changes in function, purpose, structure, use or result are intended to be covered by the claims of this patent.

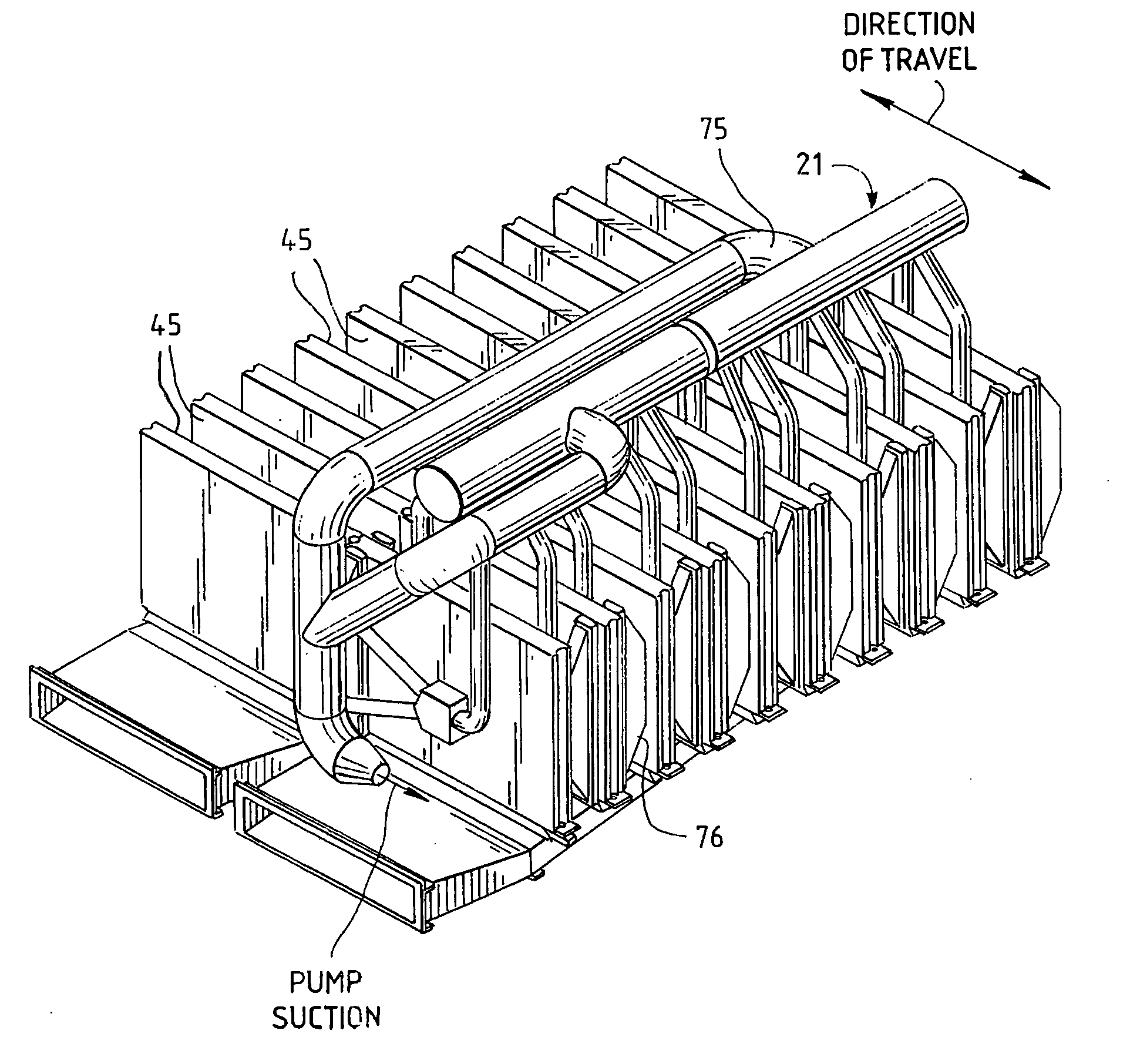

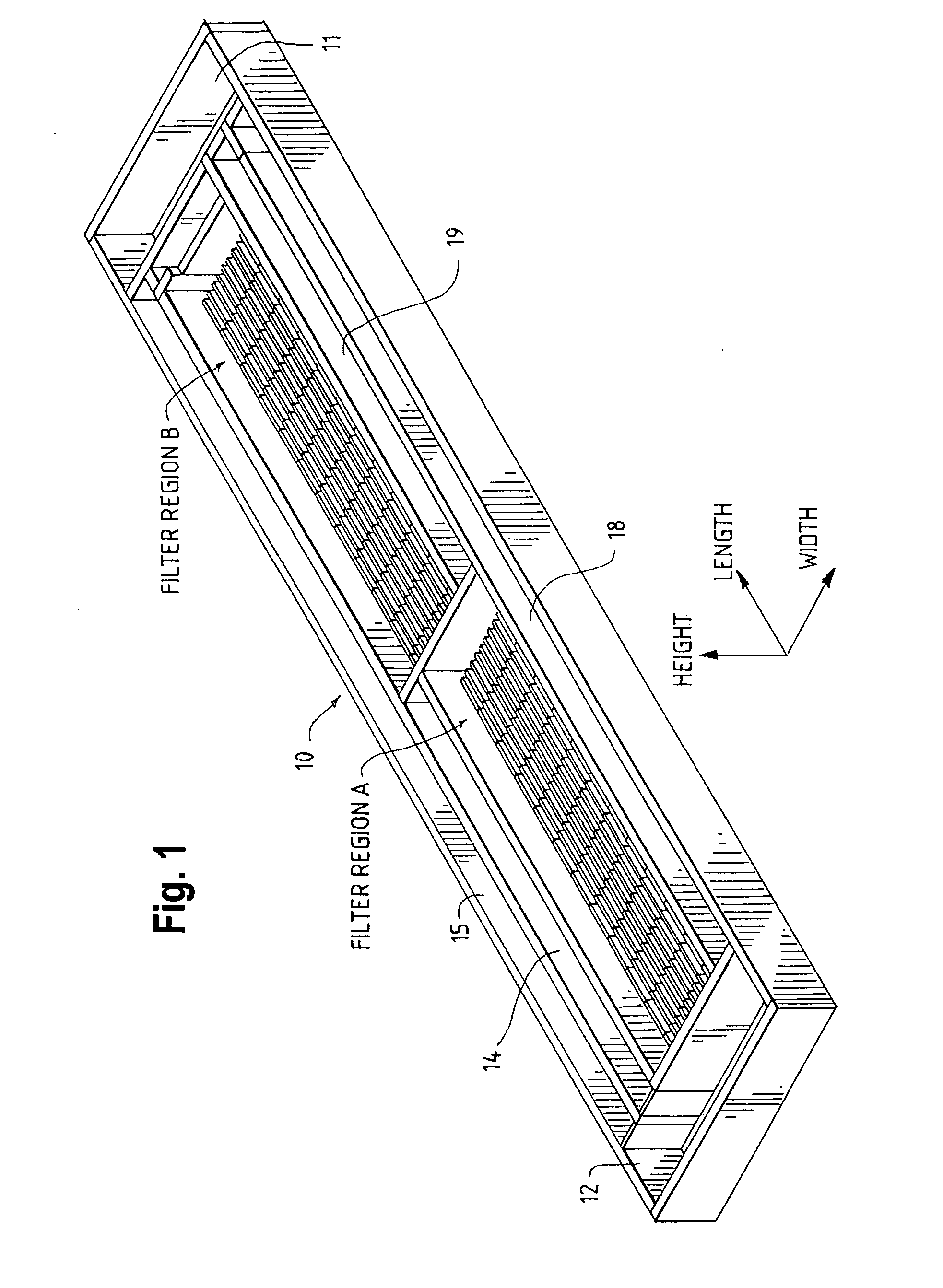

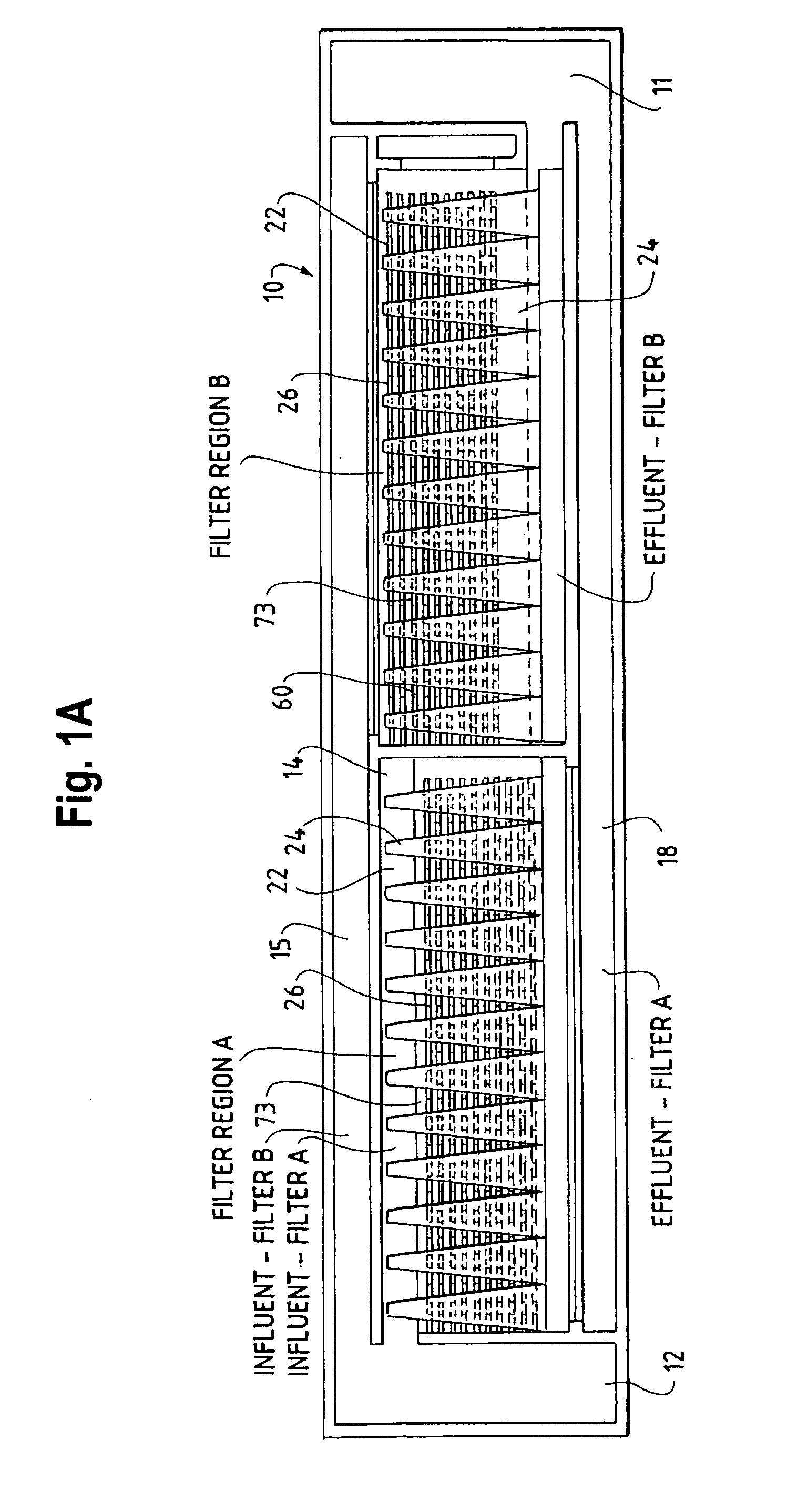

[0111]The general layout of a typical configuration of one embodiment of the present invention may be seen by reference to FIGS. 1 and 1A. The present invention may be designed to fit into the footprint of an existing filtration basin to replace, for example, a granular media gravity filtration system. It may also be designed for a completely new facility, or installed in a tank arrangement similar to conventional disk filtration. Moreover, many aspects of the present invention may be applicable to other water and wastewater treatment methods.

[0112]The present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cause selective rotation | aaaaa | aaaaa |

| suction | aaaaa | aaaaa |

| gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com