Artificial Lift Mechanisms

a technology of lift mechanism and mechanism, which is applied in the direction of positive displacement liquid engine, borehole/well accessories, piston pump, etc., can solve the problems of high stress on parts, significant wear on bearings, and the prior art mechanism does not generally incorporate the ability within itself, so as to improve the efficiency of reciprocating mechanism, reduce the cost, and lighten the weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

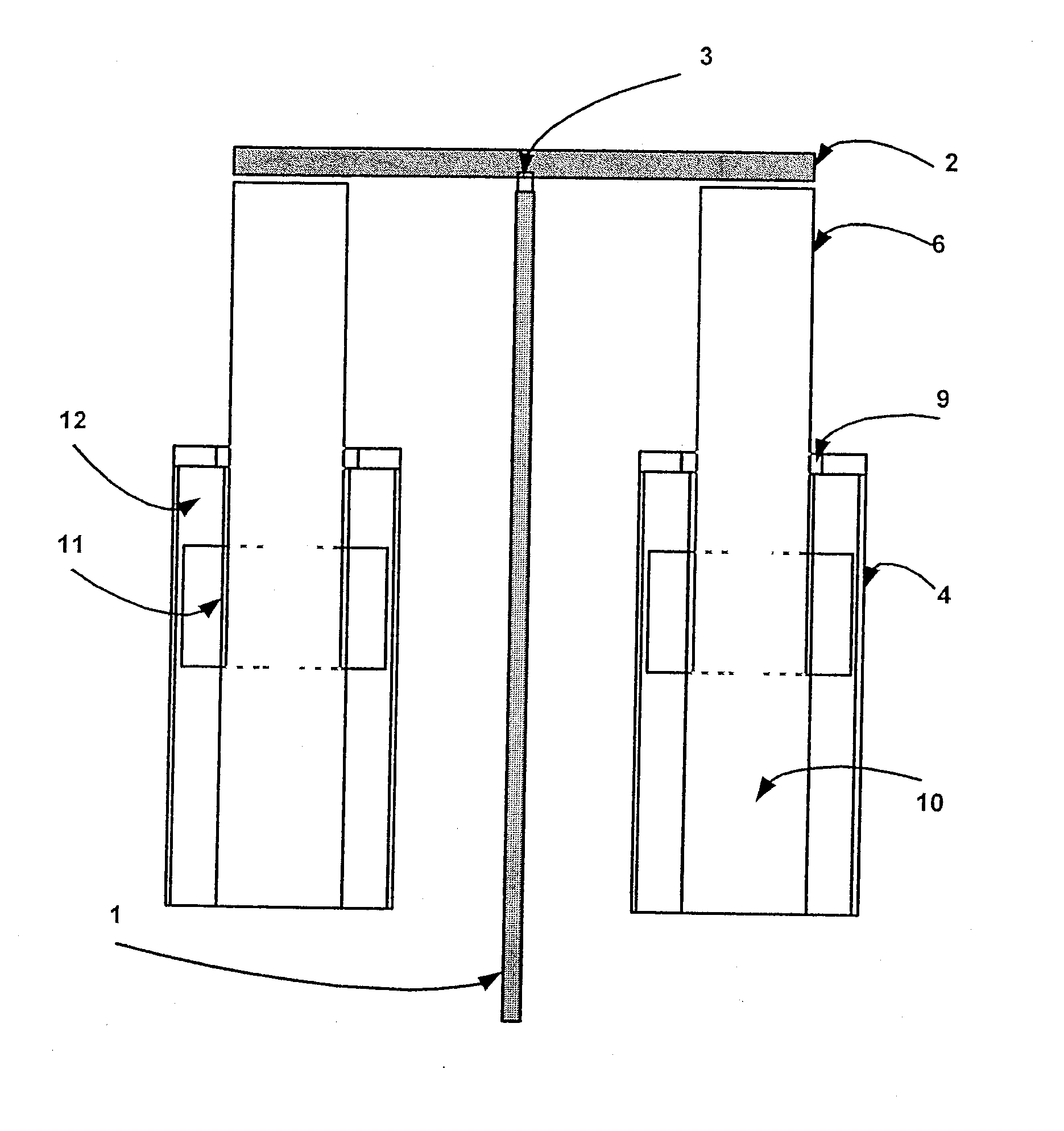

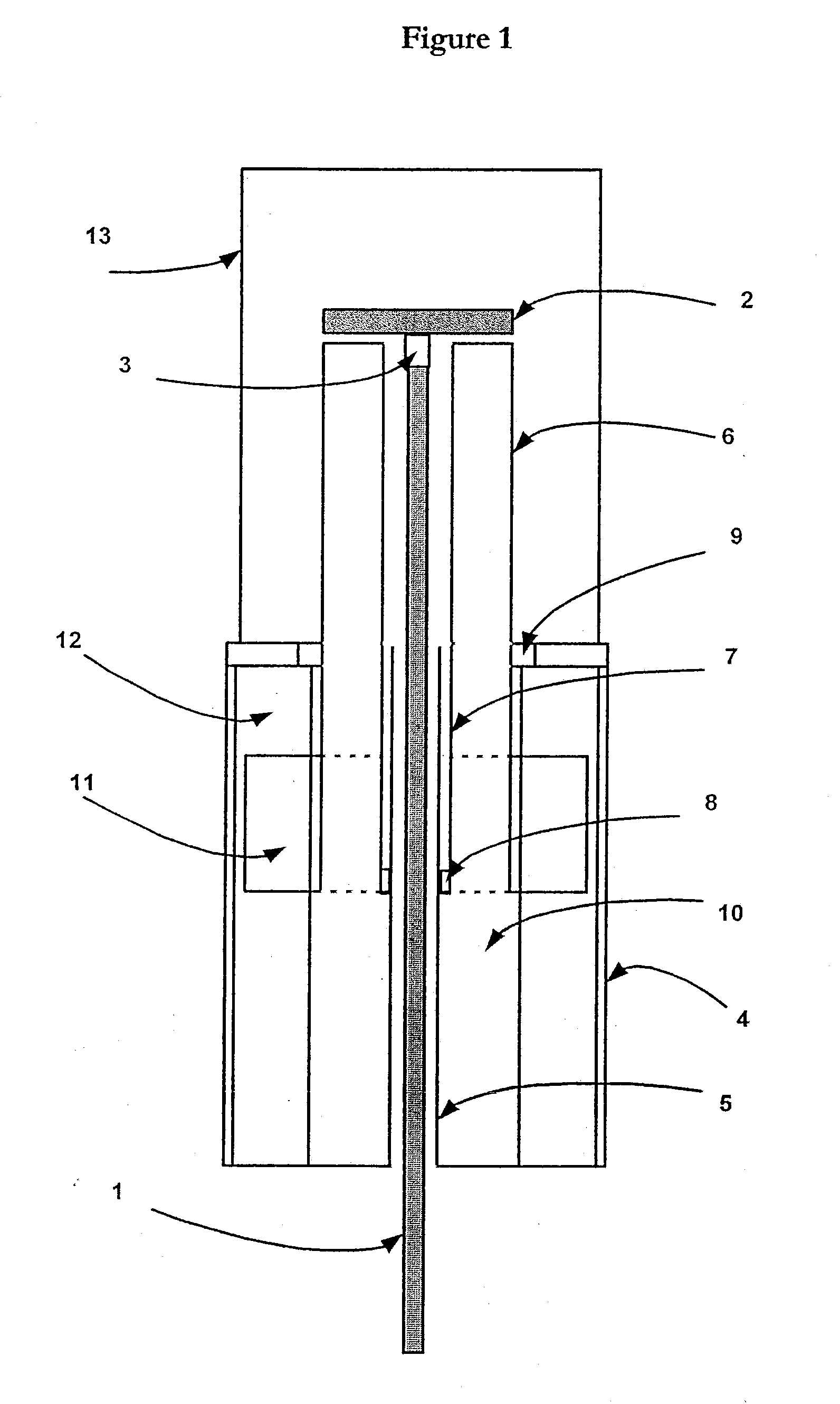

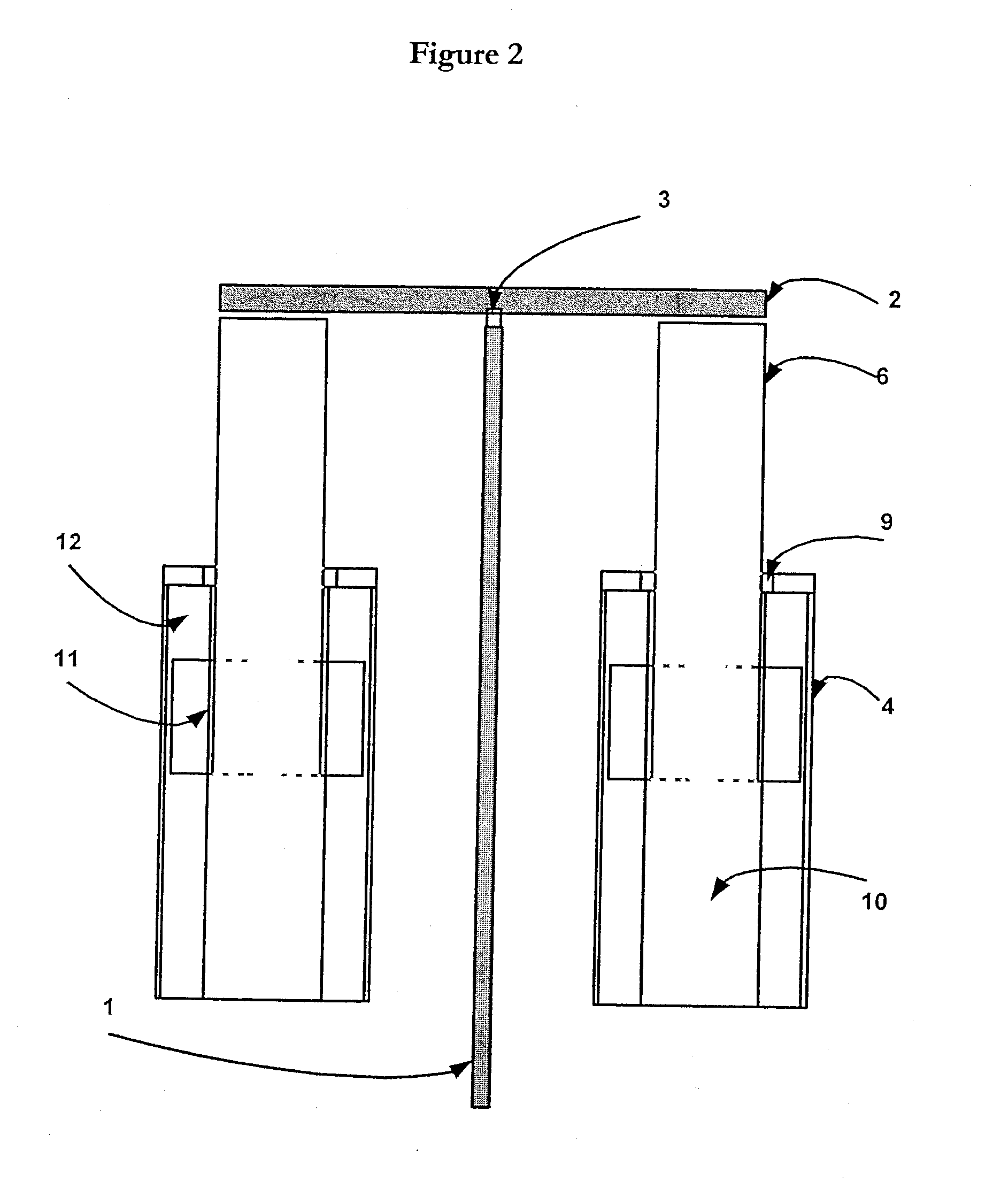

[0053]With reference to FIG. 1, shown is a diagrammatic vertical cross section of a basic cylindrical mechanism in which the polished rod of the pump string 1 is suspended from a disc 2 by means of a shackle or flexible coupling 3. The flexible coupling is necessary to accommodate the small tolerances in alignment that may exist or that may momentarily occur between the axis of the machine and the direction of the applied force. The rod 1 passes through a cylindrical channel or cavity in the body of the mechanism, the channel or cavity being bounded by the upper tube 7 and the lower tube 5. The interior of the mechanism is made gas-tight by means of the seal and bearing unit 8 between the coaxial tubes 5 and 7.

[0054]The rod string 1 is raised and lowered by means of the extendible cylinder 6 to which the disc 2 is affixed on its uppermost outer surface. The cylinder 6 extends variably from the body of the machine 4 through a second bearing and seal unit 9. The position of the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com