System and Method for Full Combustion Optimization For Pulverized Coal-Fired Steam Boilers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

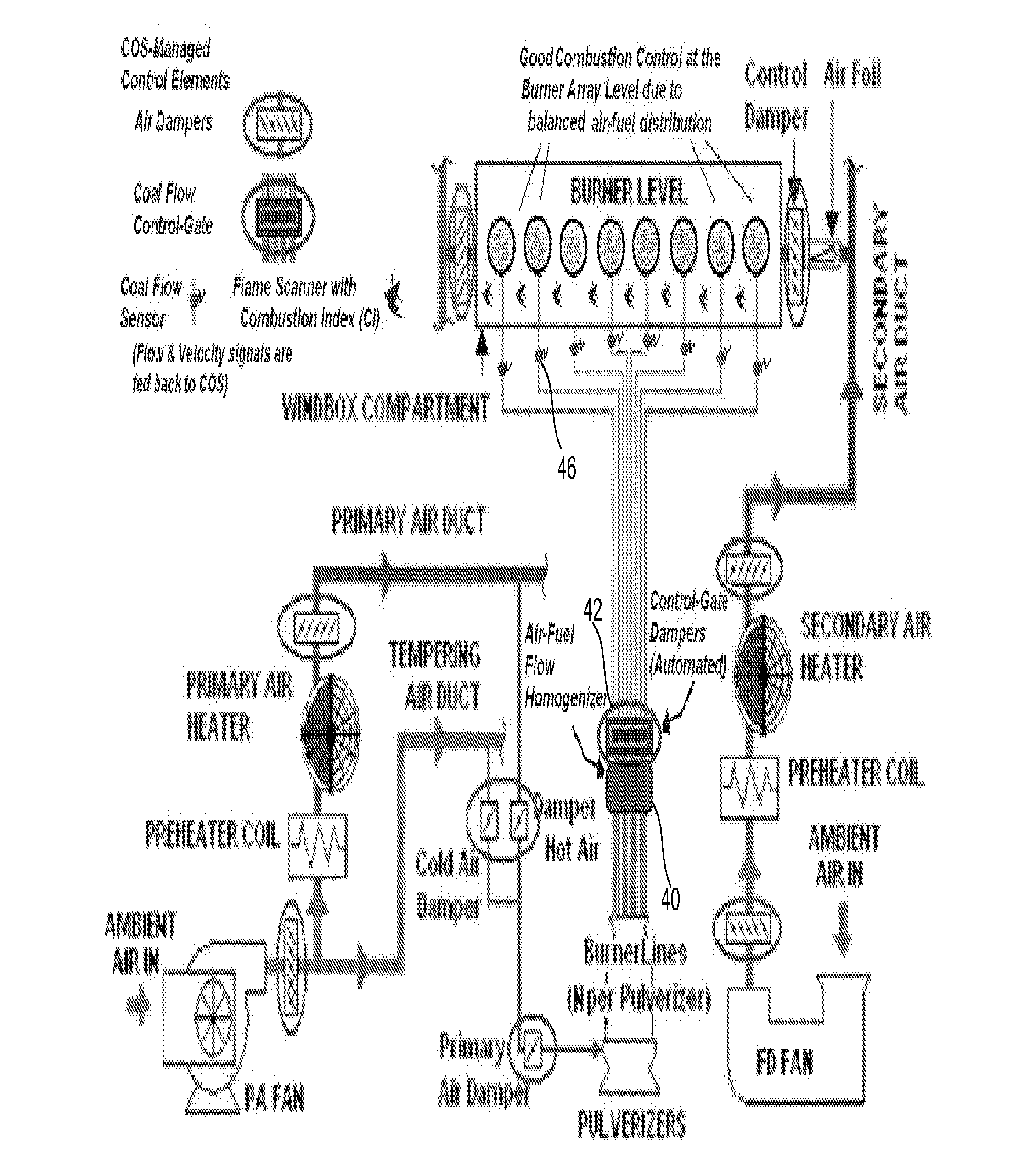

Embodiment Construction

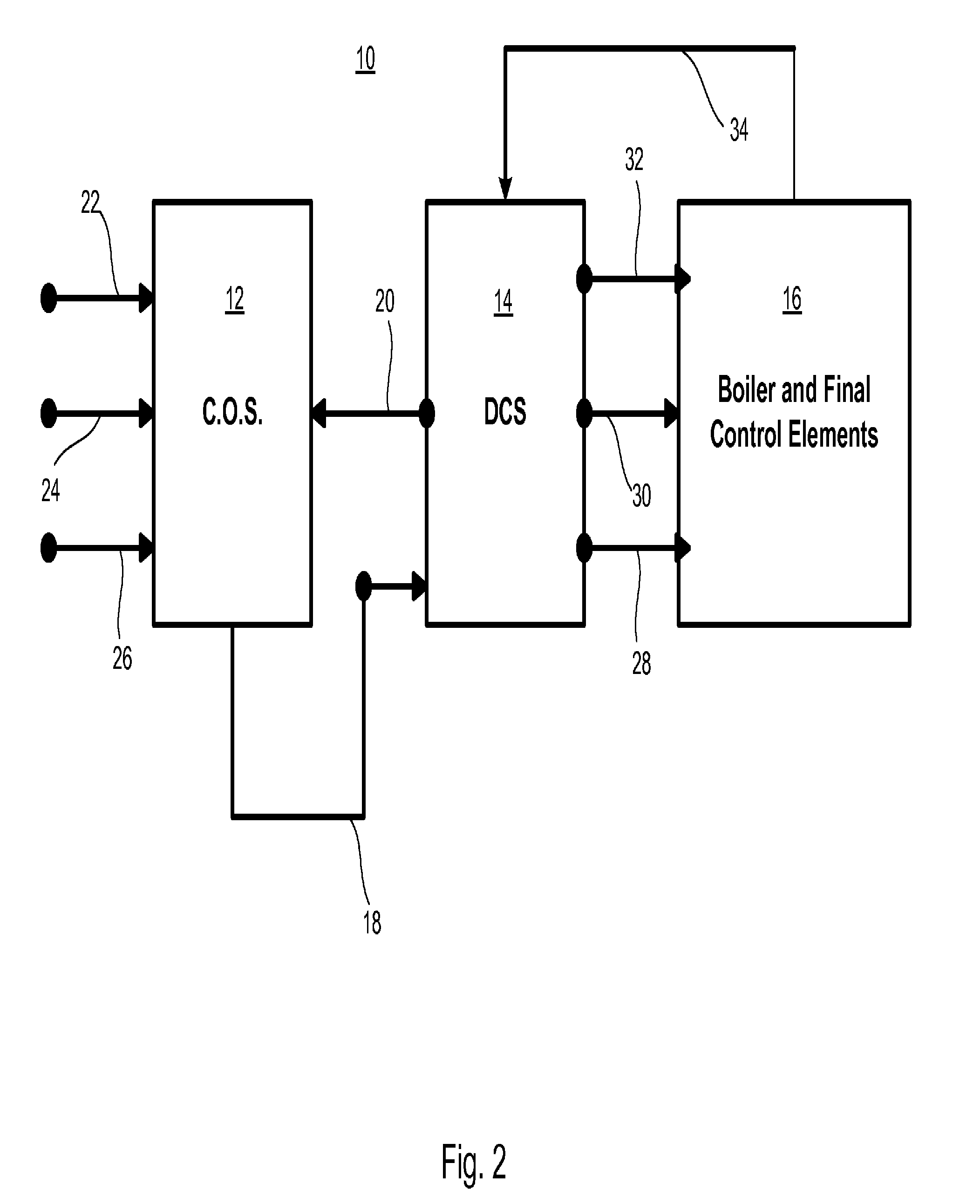

[0016]Referring now to FIG. 2, there is shown a block diagram for one embodiment of the system 10 of the present invention. System 10 includes an advanced Combustion Control and Optimization System (COS) 12. COS 12, models the multivariable nonlinear relationships of the combustion process. The relationships between signals / parameters are identified by analyzing their historical data. COS 12 is based on advanced model predictive control techniques and uses the combustion model and a cost function that describes the weighted customer optimization targets to provide setpoint and setpoint bias values 18 to the distributed control system (DCS) 14 of system 10. DCS 14 includes operator setpoints and provides process values 20 to COS 12. COS 12 has a model of the process and has as inputs the constraint variable limits 22, the controlled variable targets 24 and the manipulated variable targets and limits 26. One example of COS 12 is the Optimax Combustion Optimizer System, available from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com