Power factor correction and driver circuits

a driver circuit and power factor technology, applied in the direction of efficient power electronics conversion, electric lighting sources, electric light sources, etc., can solve the problems of increased power loss through transmission and distribution lines, increased operating costs, and additional costs for power companies, so as to increase and uniformize power and current regulation, the effect of high voltag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

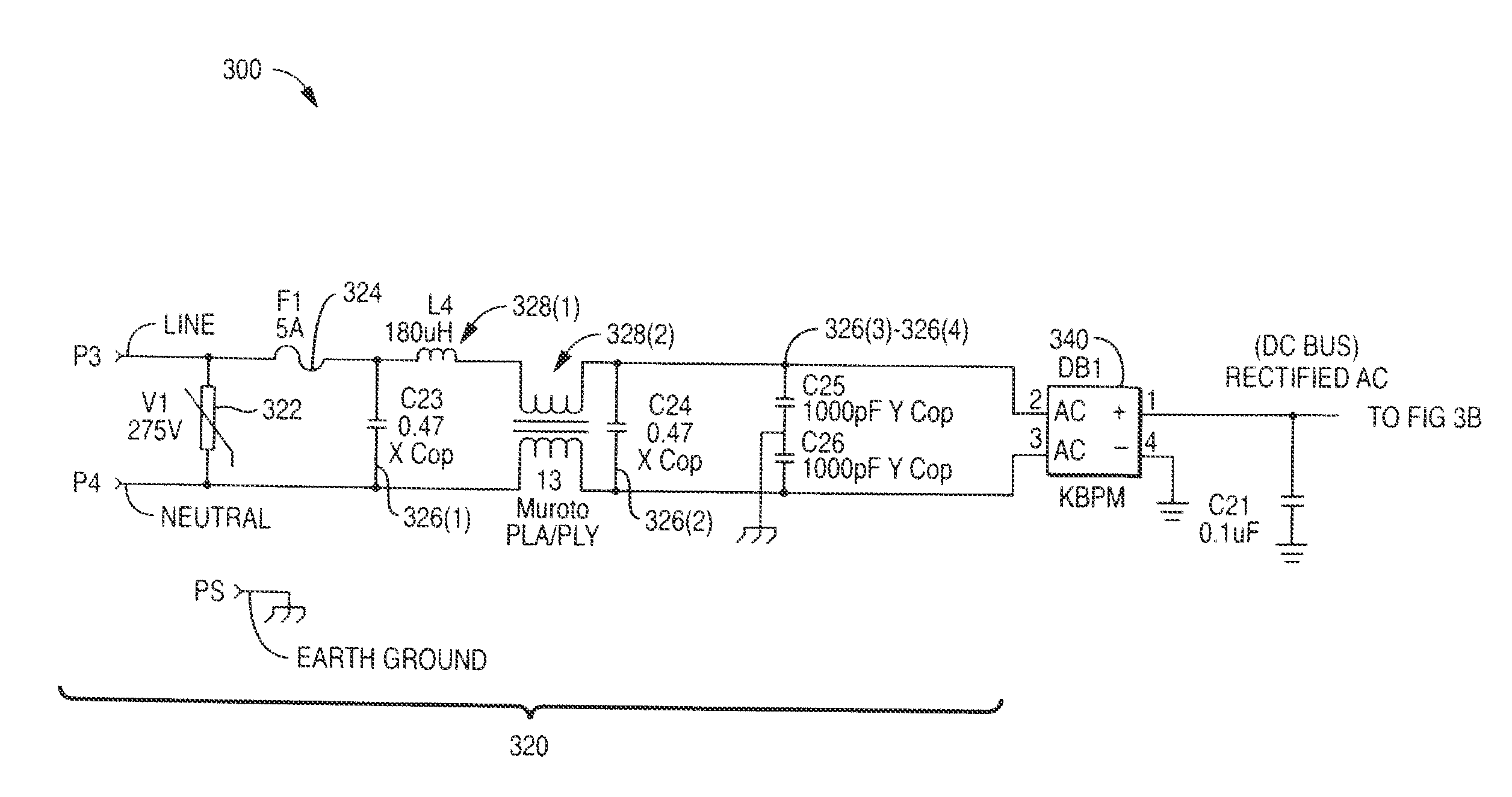

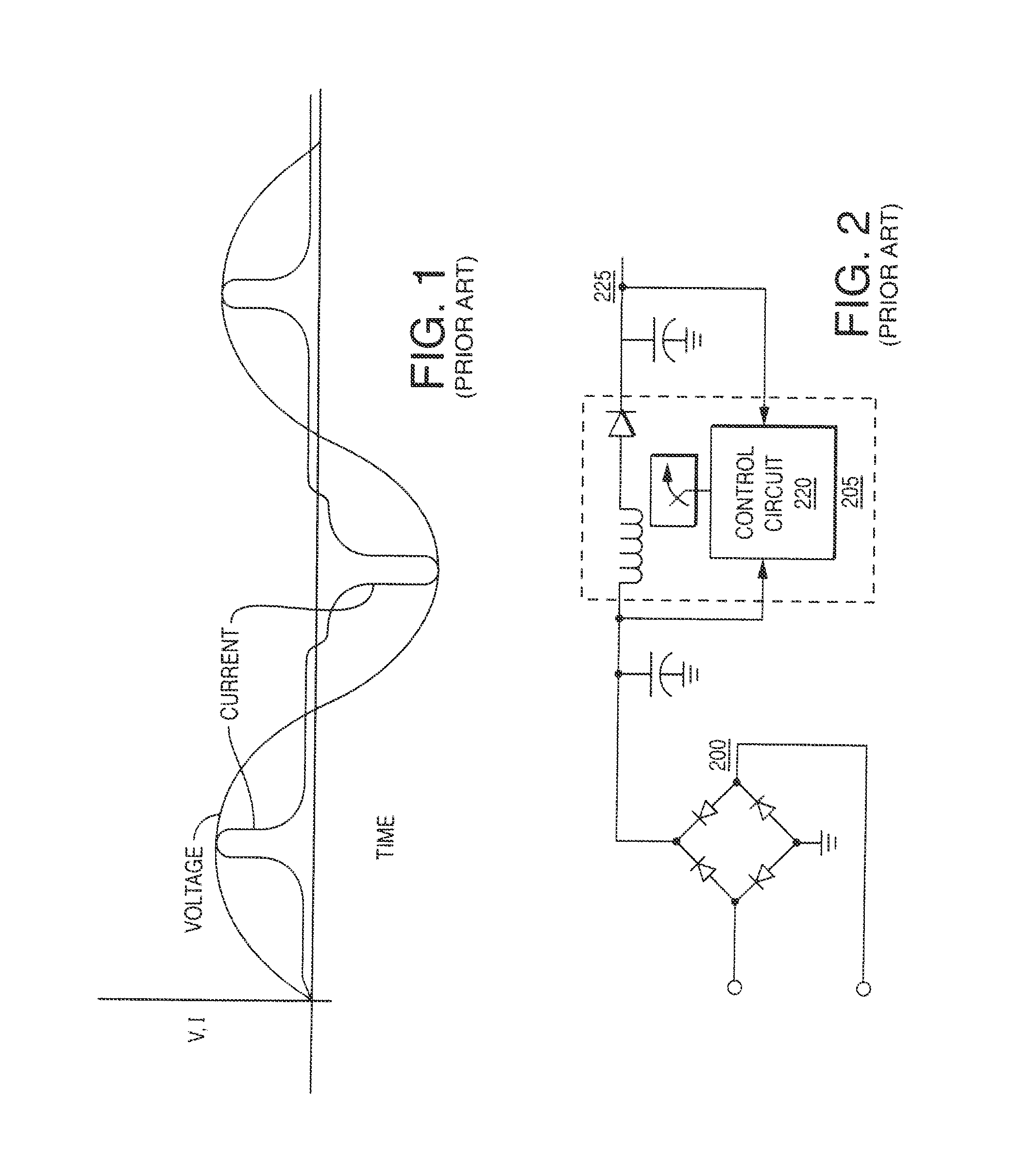

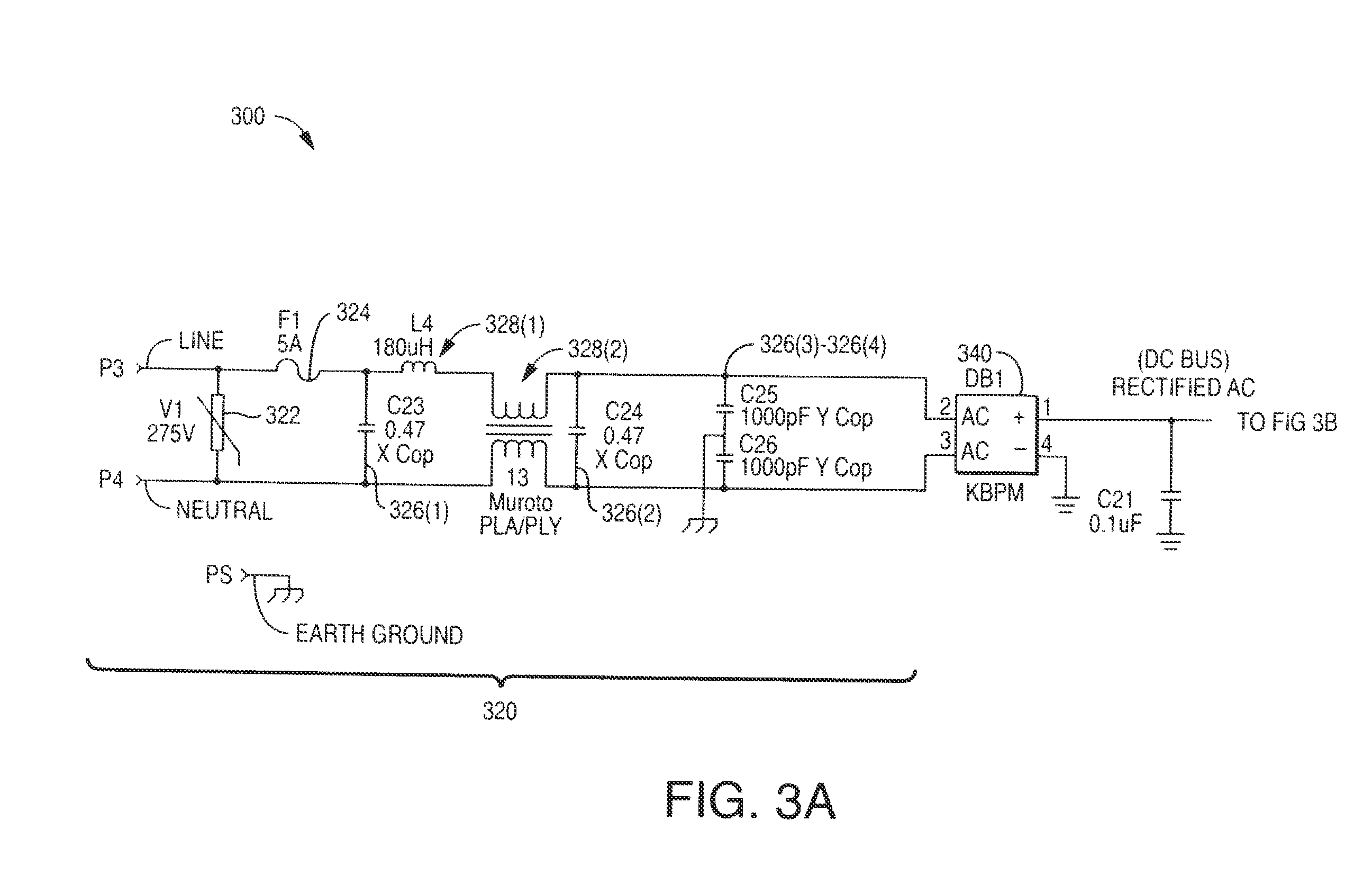

[0038]Aspects and embodiments of the present disclosure provide circuits / stages that can be utilized for power factor correction and / or electric device / component driver functionality. Such stages or circuits can be used to increase power factor correction and / or power regulation and improve service life of electrical loads. e.g., series configurations of LEDs and related components, as well as reduce thermal losses and costs related to such.

[0039]A further aspect of the present disclosure relates high-voltage driver circuits configured for electrical loads such as series arrangements of light emitting diodes. An exemplary embodiment of a drive circuit can implement a comparator and / or a voltage regulator to allow for improved output current uniformity for high-voltage applications and loads, such as series configurations of LEDs.

[0040]Aspects and embodiments of the present disclosure may be more fully understood from the description herein when read together with the accompanying dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com