Drilling unit, method for slot drilling and slotting device

a drilling unit and slotting technology, applied in drilling pipes, directional drilling, cutting machines, etc., can solve the problems of serious damage to the body and the guide increased fluid pressure, and shorten etc., to achieve the effect of increasing fluid pressure, easy connection and disconnection, and prolonging the operating life of the slotting devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

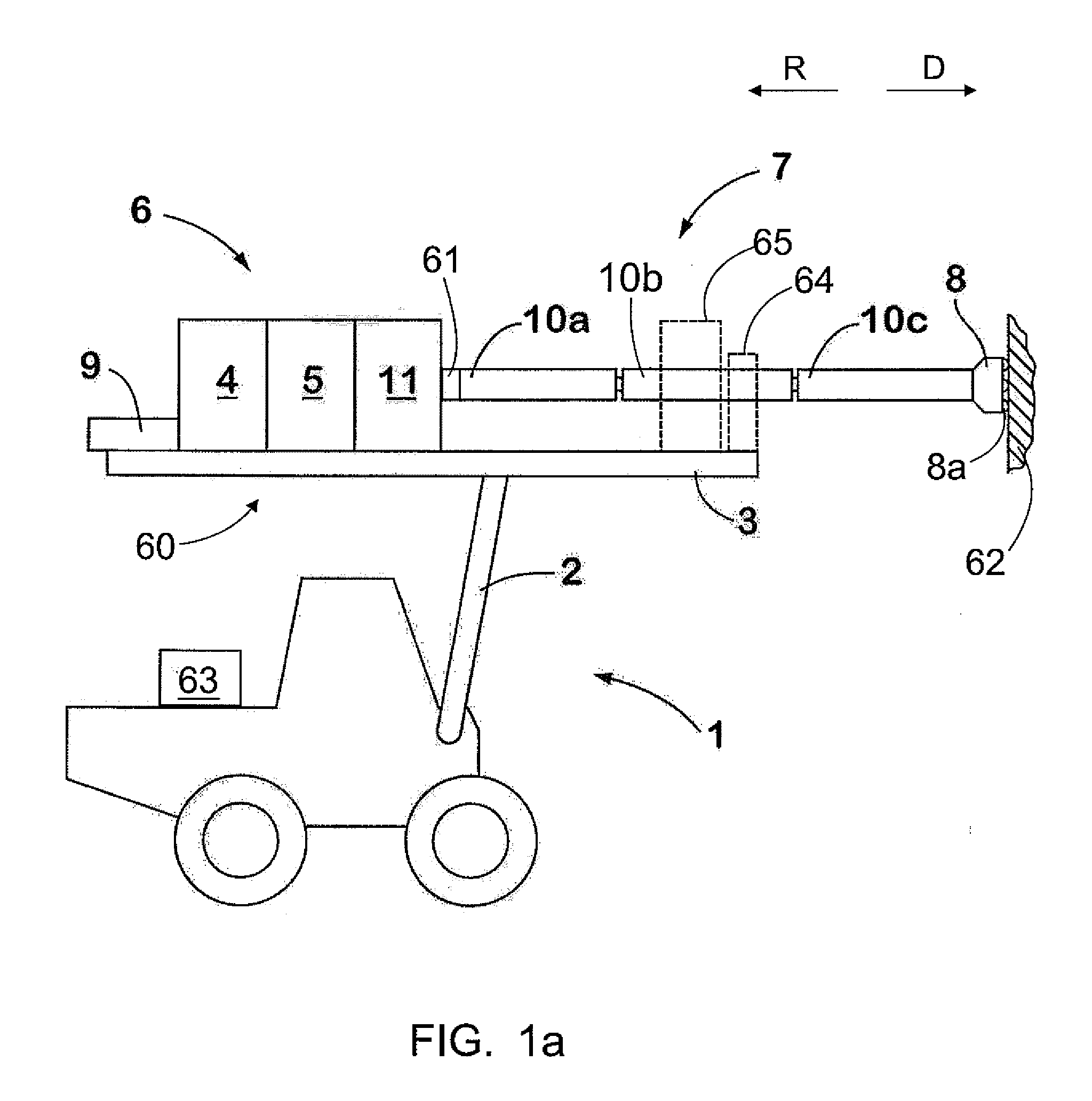

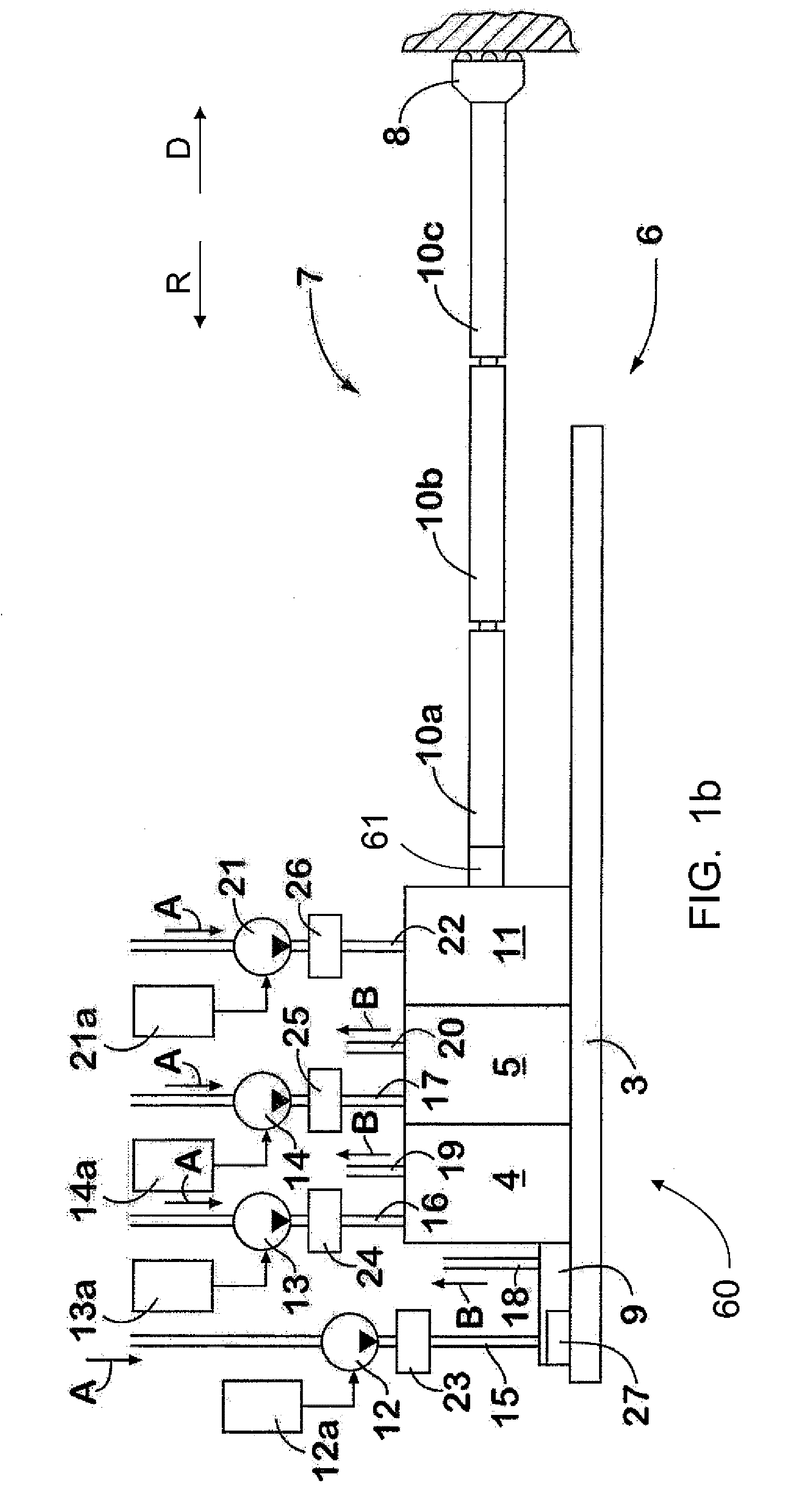

[0034]FIG. 1a is a schematic illustration of a rock drilling rig 1, that includes a boom 2, at the end of which there is a rock drilling unit 60. The rock drilling unit 60, which is shown more detailed in FIG. 1b, comprises a feed beam 3 with a rock drilling machine 6 including a percussion device 4 and possibly a rotating device 5. In general, the percussion device 4 comprises a percussion piston that is operated by a pressure medium, and strikes the upper end of a tool 7 or a connecting piece arranged between the tool 7 and the percussion device 4, such as a drill shank 61. Naturally, it is possible to generate impact pulses in the percussion device 4 in some other manner, for example electrically or without a reciprocating striking piston. The proximal end of the tool 7 is connected to the rock drilling machine 6 by means of the shank 61, and at the distal end of the tool 7 there is a fixed or detachable bit 8 for breaking rock. Typically, the bit 8 is a drill bit with buttons 8a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com