Transparent Conducting Components and Related Electro-Optic Modulator Devices

a transparent conducting component and modulator technology, applied in optics, instruments, nanotechnology, etc., can solve the problems of limited low-voltage operation of prior high-speed electro-optic device structures, limited metal absorption, and limited metal electrode closeness, etc., to achieve high modulation speed, not limited, and high eo coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0062]For a device structure of such embodiments, the waveguide core layer can be any EO material, such as a poled polymer, self-assembled polymer, LiNbO3, BaTiO3, a semiconductor (e.g., GaAs, AlAs, AlGaAs, InP, InGaAs, InGaAsP) or others. PEPCOOH (e.g., a self-assembled polymer; that is, Pyridine-Ethene-Pyrrole-Carboxylic Acid) is used as an example (refractive index n=1.9 at 1.55 μM wavelength). The TC cladding can be any known TC or TCO, such as but not limited to the polymeric materials described herein, as well as ZnO, ZIO, GIO, GITO, ZITO, ITO, CdO or others. Here, ZITO can be used for purpose of example (refractive index n=1.7 at 1.55 μM wavelength). For a device structure, the ridge etching can stop anywhere from the top TCO to the bottom metal, which will give a different mode size of waveguide, single mode or multi mode. Three examples are presented: a 1st example with etching to the bottom TCO after the EO material, a 2nd example with etching to the bottom metal, and a 3r...

example 1a

1st Example with Etching to Bottom of TCO after EO Material

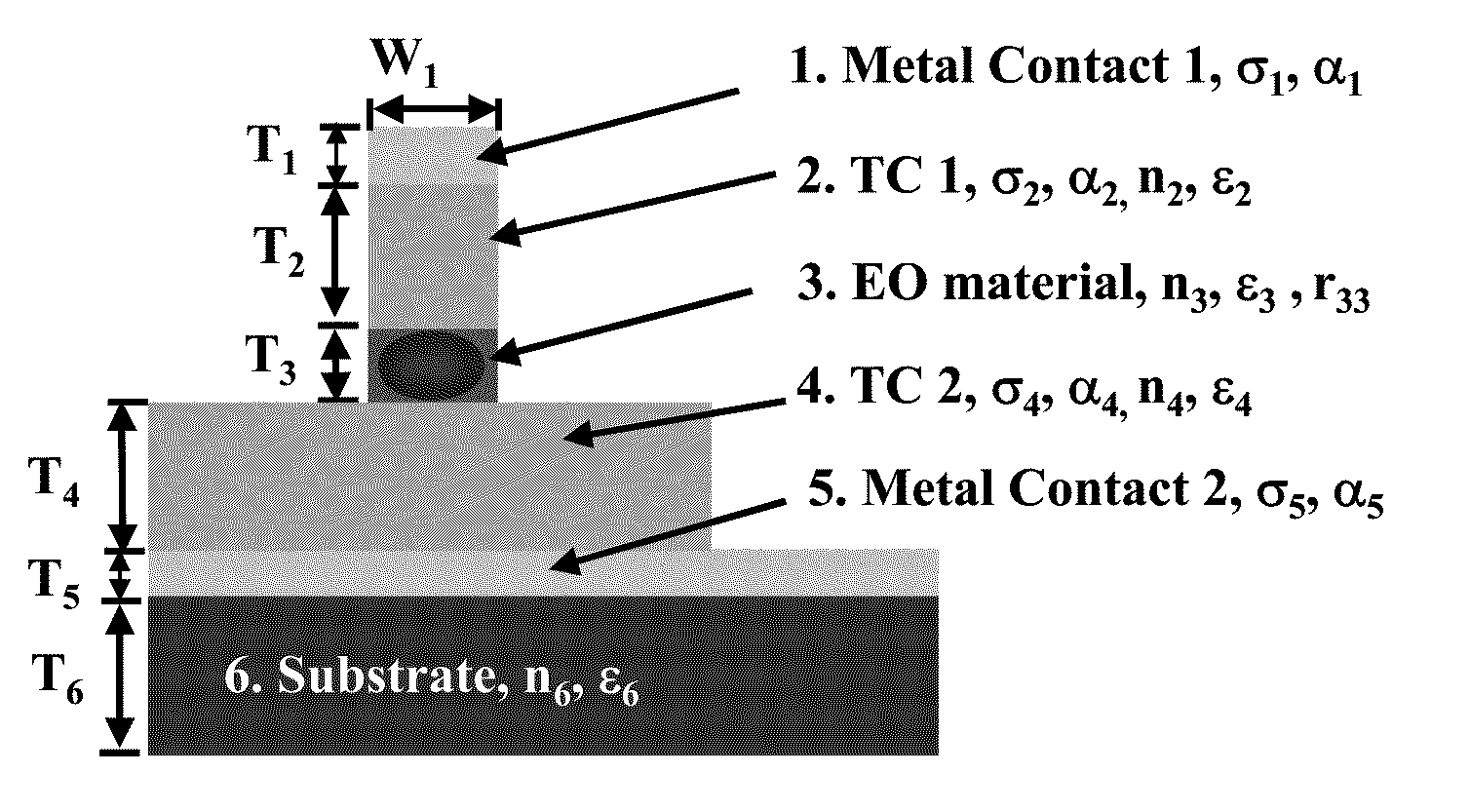

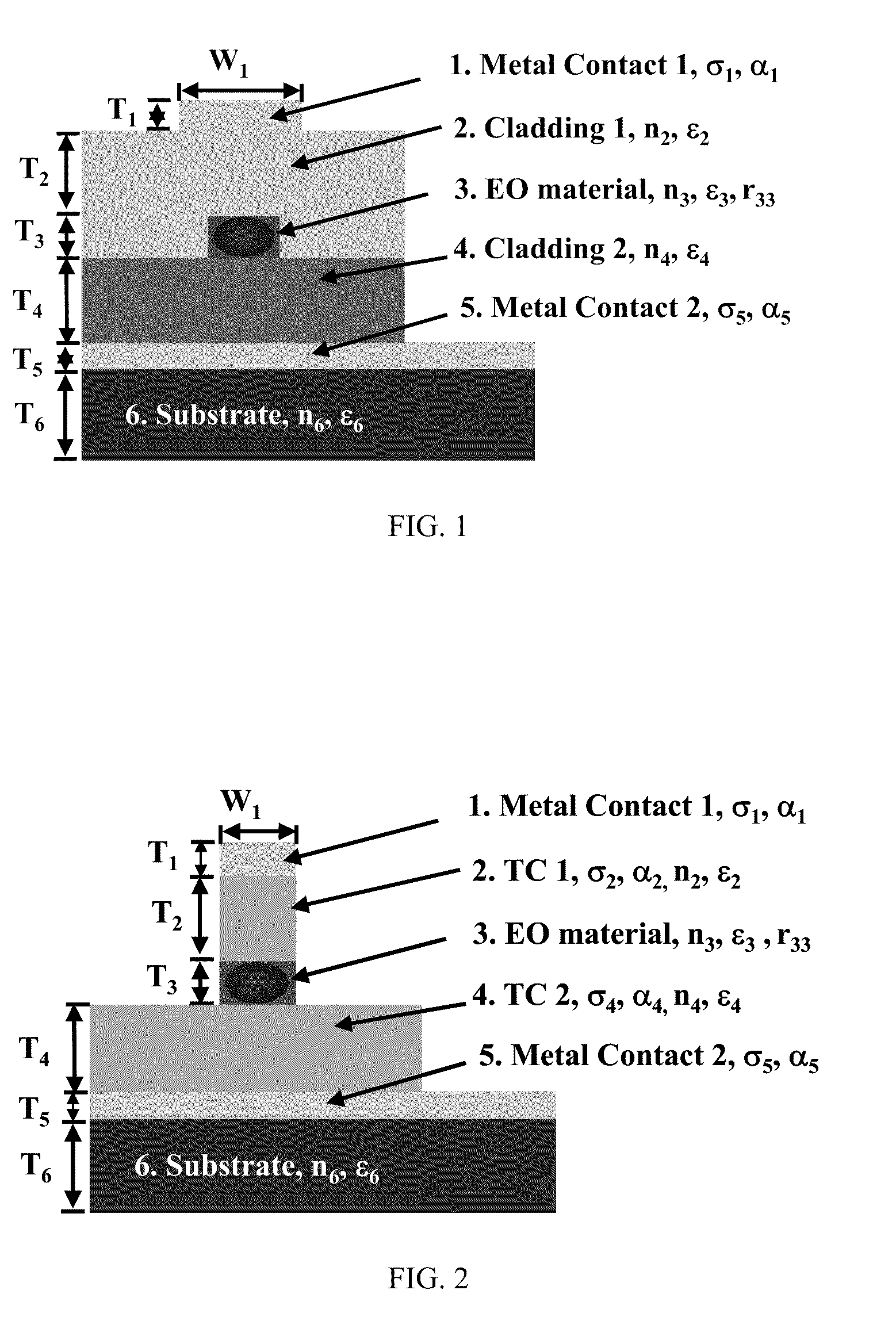

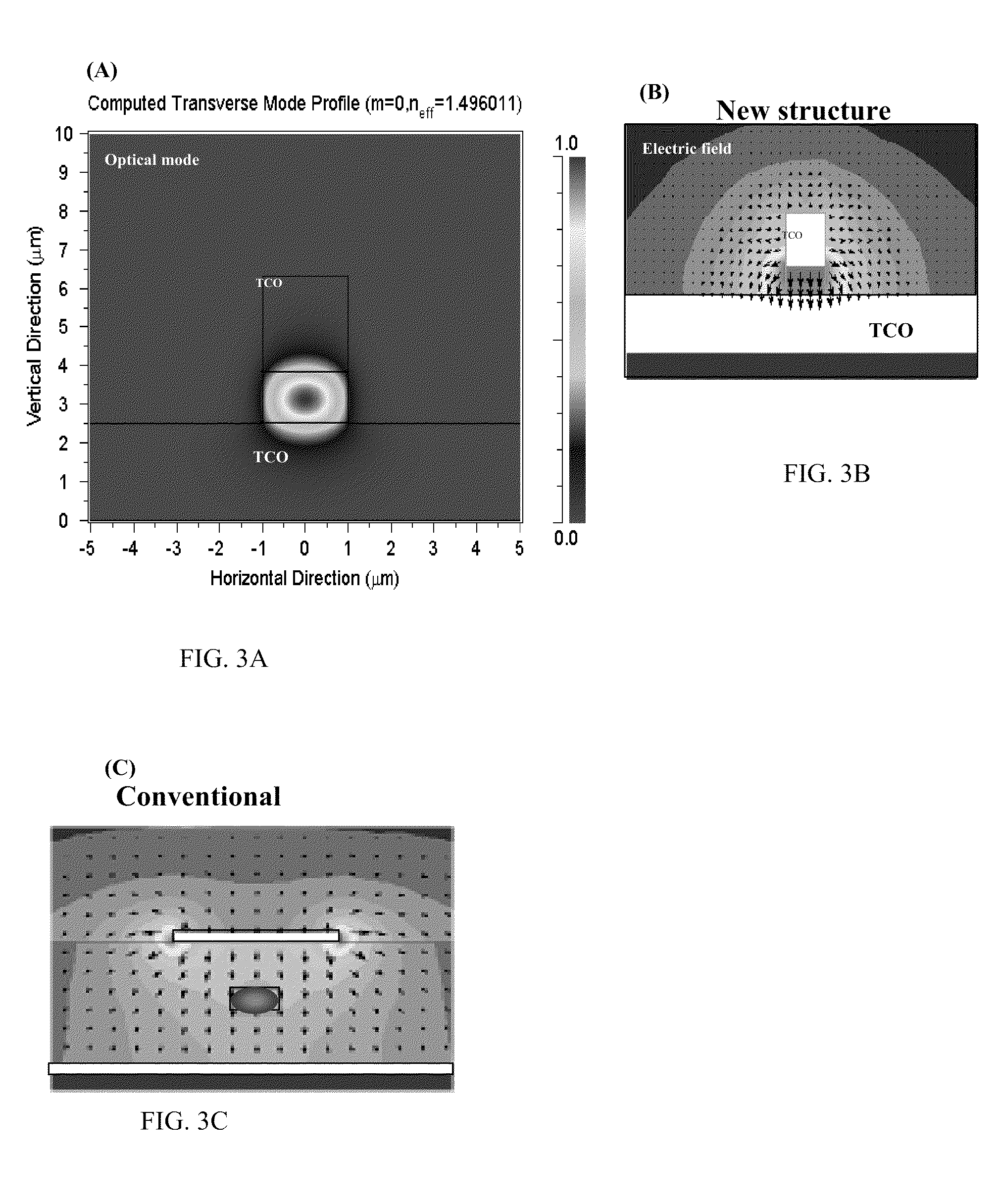

[0063]With reference to the device structure shown in FIG. 2, a TCO thickness is 2 μM (e.g., thick enough to reduce metal loss αL<0.3d) and core layer is 1 μM; waveguide width is 2 μM. As shown in FIG. 3, simulation results clearly show good optical confinement and much stronger electric field (FIG. 3B) cross the EO material compared to a conventional structure (FIG. 3C).

[0064]A planar structure as the bottom TCO instead of a ridge structure will give a smaller resistance due to the larger area, ˜2× different (R top=2.19R bottom for this example). The top and bottom TCO can be single layer or multi-layer with the same or different electric conductivity.

[0065]To illustrate a single layer TC electrode, a waveguide core layer is PEPCOOH with an EO coefficient r33=120 pm / V and a refractive index n=1.9. The cladding layer is ZITO with a refractive index n=1.7. With three refractive indices, the core thickness and cladding thickne...

example 1b

2nd Example with Etching to Bottom Metal after TCO

[0074]Another device structure is shown in FIG. 4. With this structure, optical confinement is stronger than that available using the structure of Example 1a. The waveguide can be narrower for nano-scale application. TC parameter calculations for a target Vπ and frequency responses are based on the principles discussed in Example 1a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequencies | aaaaa | aaaaa |

| modulation voltage | aaaaa | aaaaa |

| switching voltages | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com