Lubricious microfludic flow path system

a flow path and microfluidic technology, applied in the field of flow cytometers, can solve the problems of reducing the purity of collected populations, the flow rate, and the yield of analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

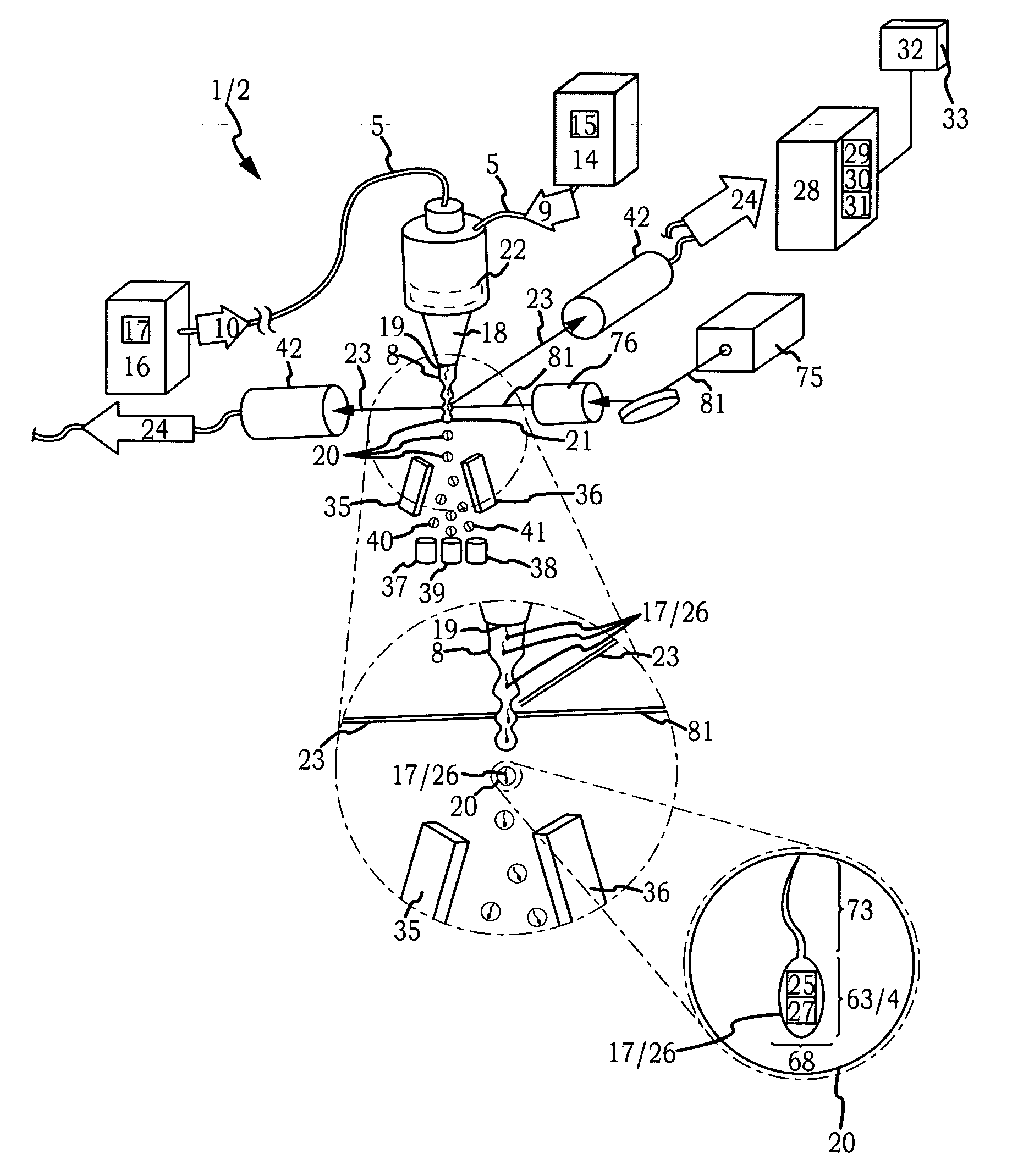

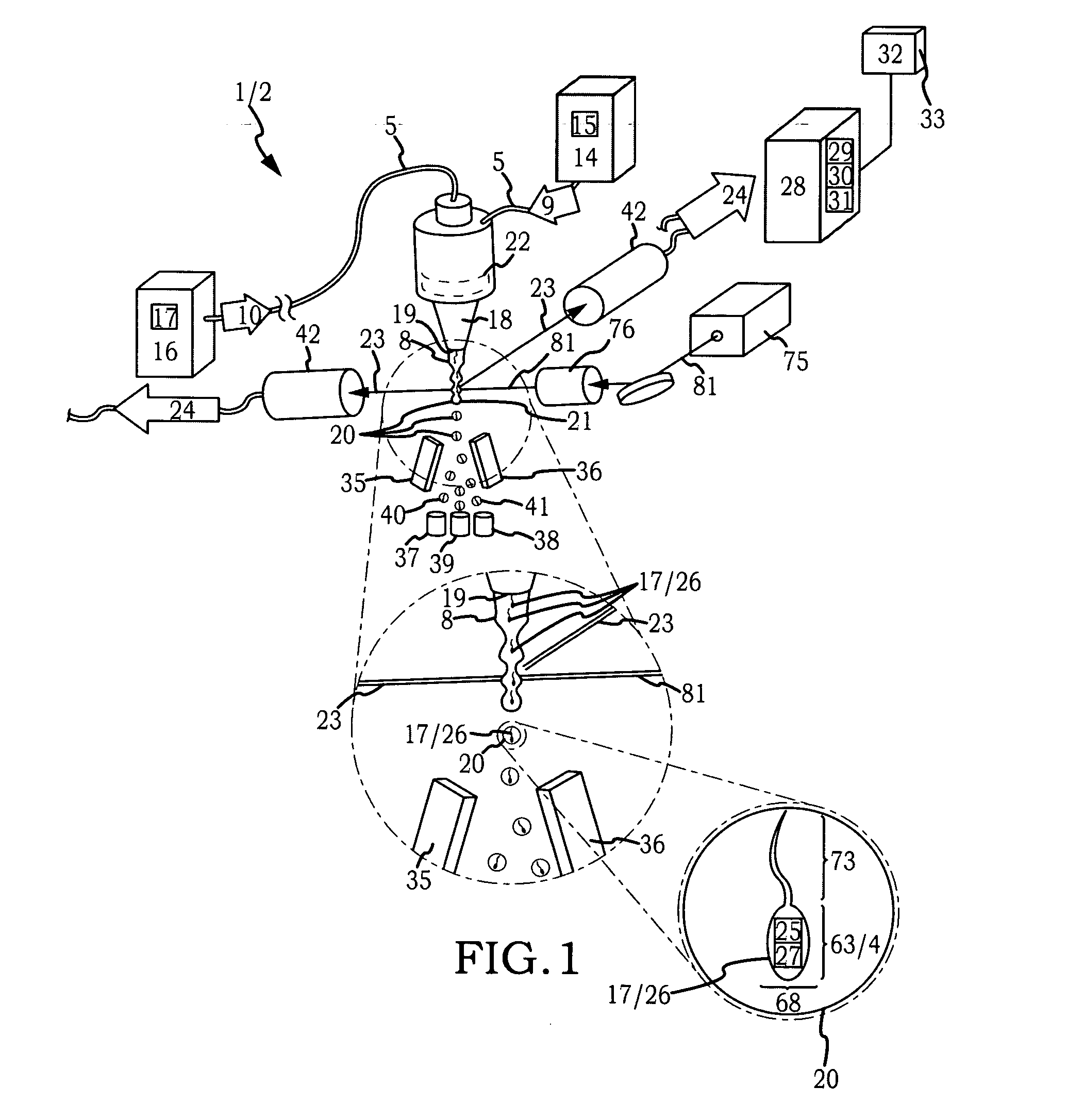

[0094]Modification of Flow Cytometer Nozzle Assemblies and Operation of Flow Cytometers. Four substantially identical conventional nozzle assemblies (43) for a MOFLO® SX flow cytometer manufactured by Beckman Coulter, Fort Collins, Colo. were utilized to provide the standard and experimental nozzle assemblies for comparative trials. A lubricious layer (7) of the hydrophilic polymer poly(vinyl pyrollidone) was applied to the internal substrate surface (6) of the sample fluid conduit (52) and the internal surface of the nozzle (18) of two of the four nozzle assemblies (43). All four of the nozzle assemblies provided a 70 μM diameter nozzle orifice (19). Each of the two standard nozzle assemblies (43) and each of the two experimental nozzle assemblies (43) having the lubricious layer (7) applied as above described were installed onto otherwise substantially identical MOFLO SX® flow cytometers and operated side by side.

Composition of Solutions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com