Temperature and low water monitoring for boiler systems

a technology for low water monitoring and boiler systems, applied in the field of safety devices, can solve the problems of not being able to replace the sensor of an existing aquastat, providing high temperature limit without provision to turn the burner, and reluctance to accommodate multiple tappings for water cutoff probes and temperature sensor probes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

[0036]In describing the preferred embodiment of the present invention, reference will be made herein to FIGS. 1-9 of the drawings in which like numerals refer to like features of the invention.

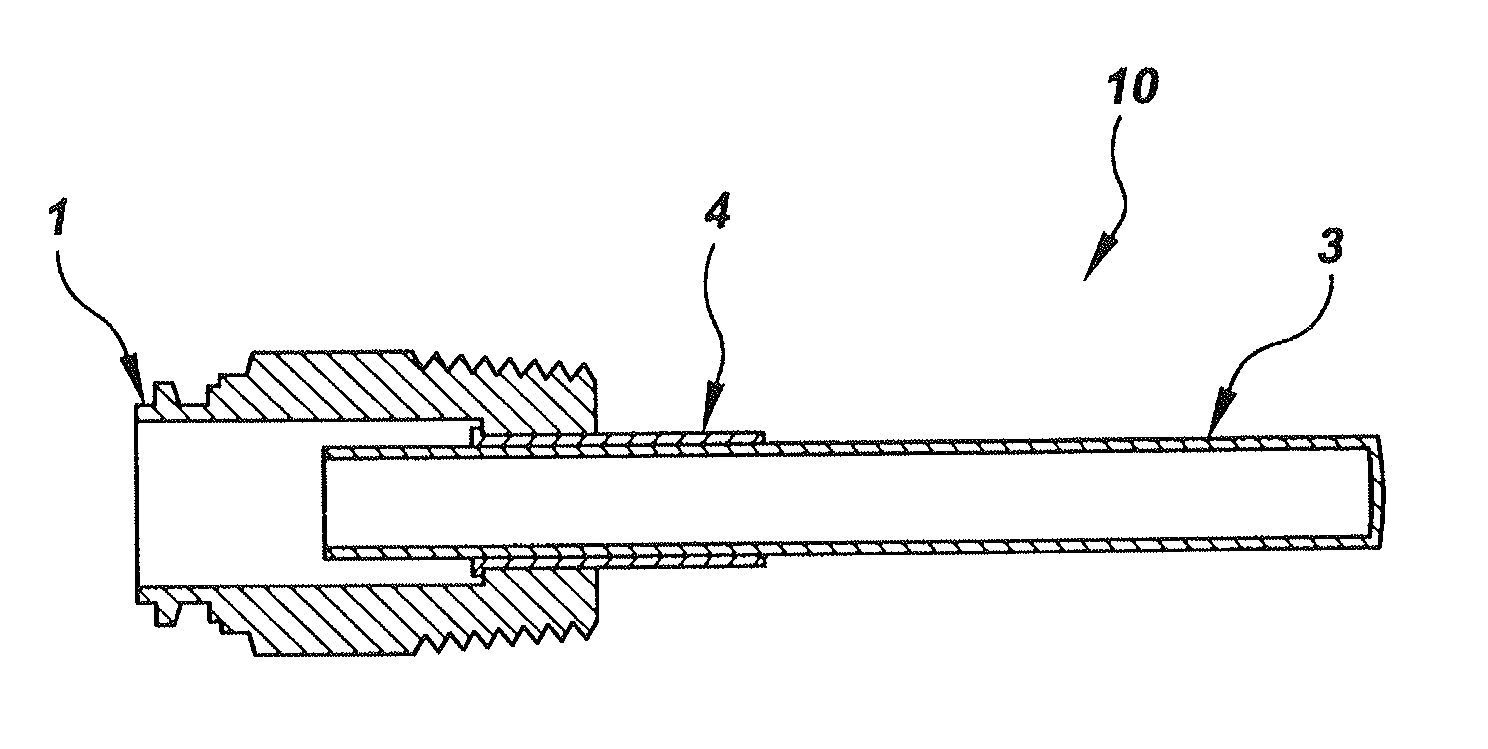

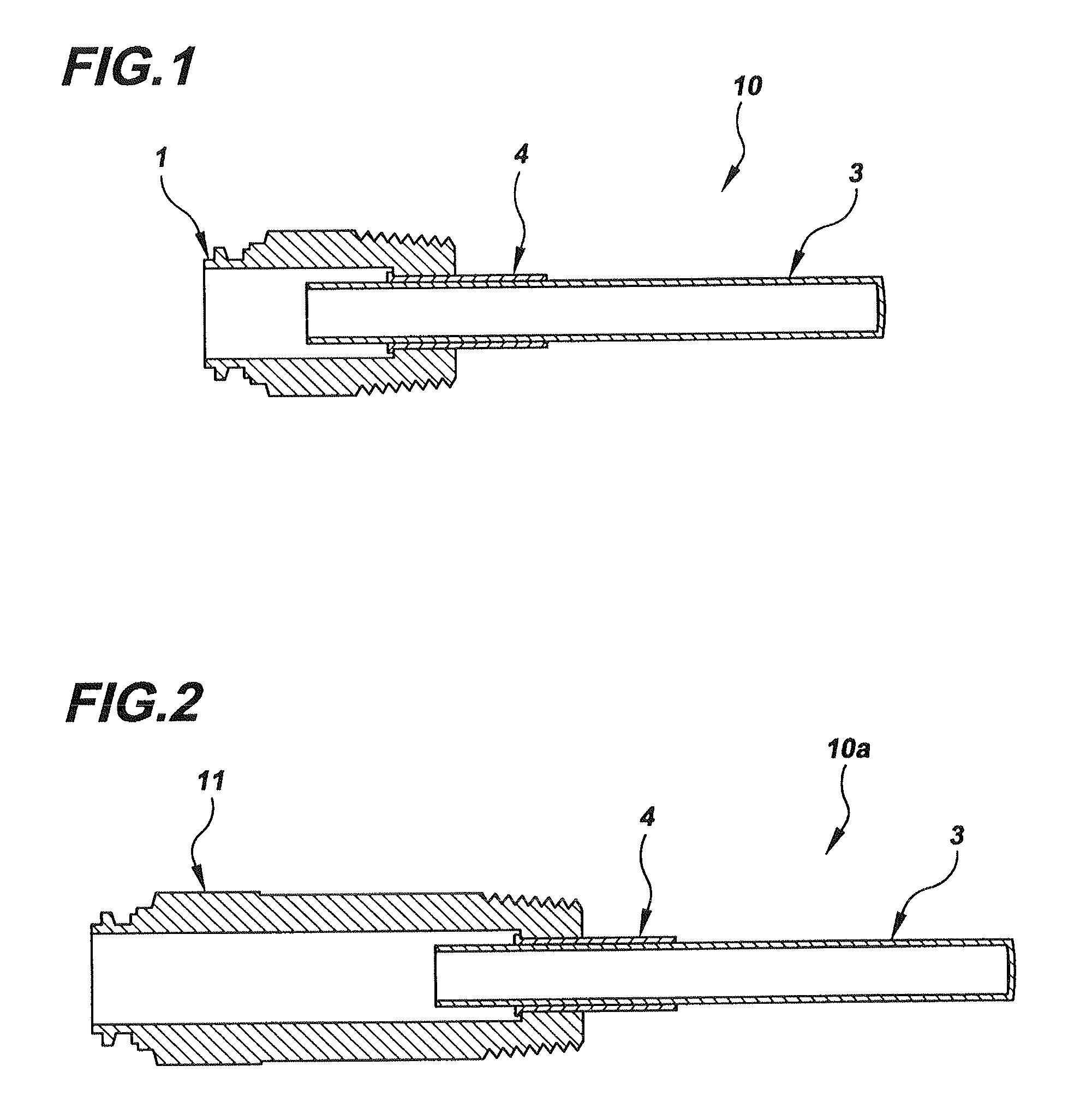

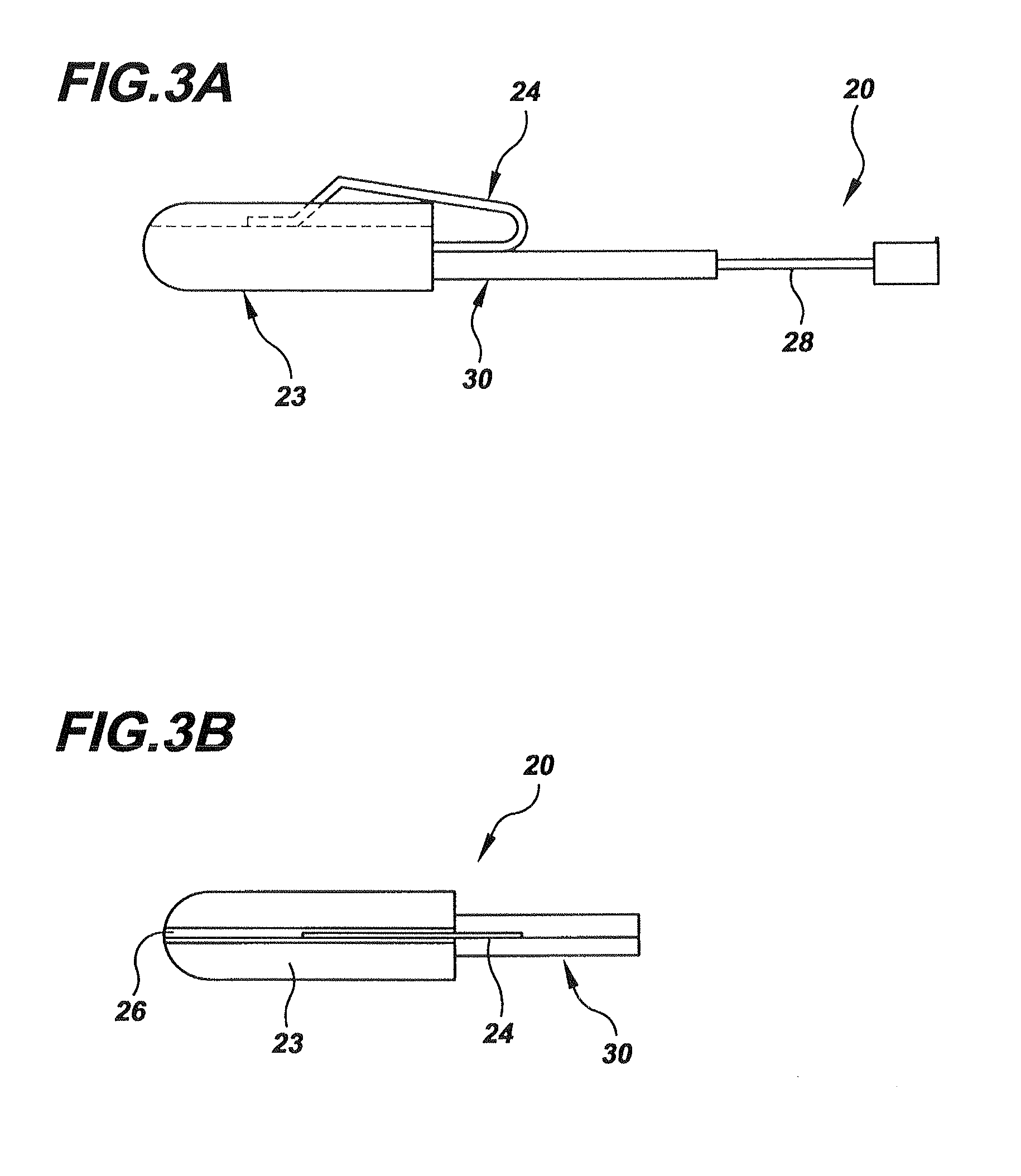

[0037]The present invention teaches a dual functionality of temperature control measurement and low water cut-off measurement within a single tapping in a boiler. This dual functionality combines a low water cut-off and temperature sensor into one control utilizing a sensing element suitable for use in an existing ¾″ tapping for typical boilers. The tappings generally comprise a threaded brass nut for insertion in a boiler housing wall, a hollow, cylindrical temperature / low water cut-off well for protecting and securing the sensors, and an insulator (dielectric), which electrically separates the brass nut from the cylindrical well. The sensor well allows a user to insert the temperature sensor and low water cutoff sensor without draining the system. Importantly, the sensor well may be used fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistance | aaaaa | aaaaa |

| operating temperature | aaaaa | aaaaa |

| operating temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com