C+n austenitic stainless steel having high strength and excellent corrosion resistance, and fabrication method thereof

a technology high strength, applied in the field of c + n austenitic stainless steel, can solve the problems of difficult improvement of mechanical properties of austenitic stainless steel using heat treatment methods, adverse effects of nickel (ni) on human health and environment, and high-nitrogen stainless steel has not been commercialized, so as to reduce the content of nickel (ni) and avoid the effect of high alloying element cost and harmful to the environment and human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 8

Fabrication of Austenitic Stainless Steel According to the Present Invention

[0050]In the fabrication of an austenitic stainless steel according to an embodiment of the present invention, a ferrochromium master alloy (e.g., Fe-60% Cr master alloy) was used as a chromium (Cr) source which hardly melts due to the high melting point, and a ferromanganese master alloy (e.g., Fe-50% Mn master alloy) was used as a manganese (Mn) source to prevent a generation of manganese (Mn) fume and a segregation in molten metal due to the low vapor pressure.

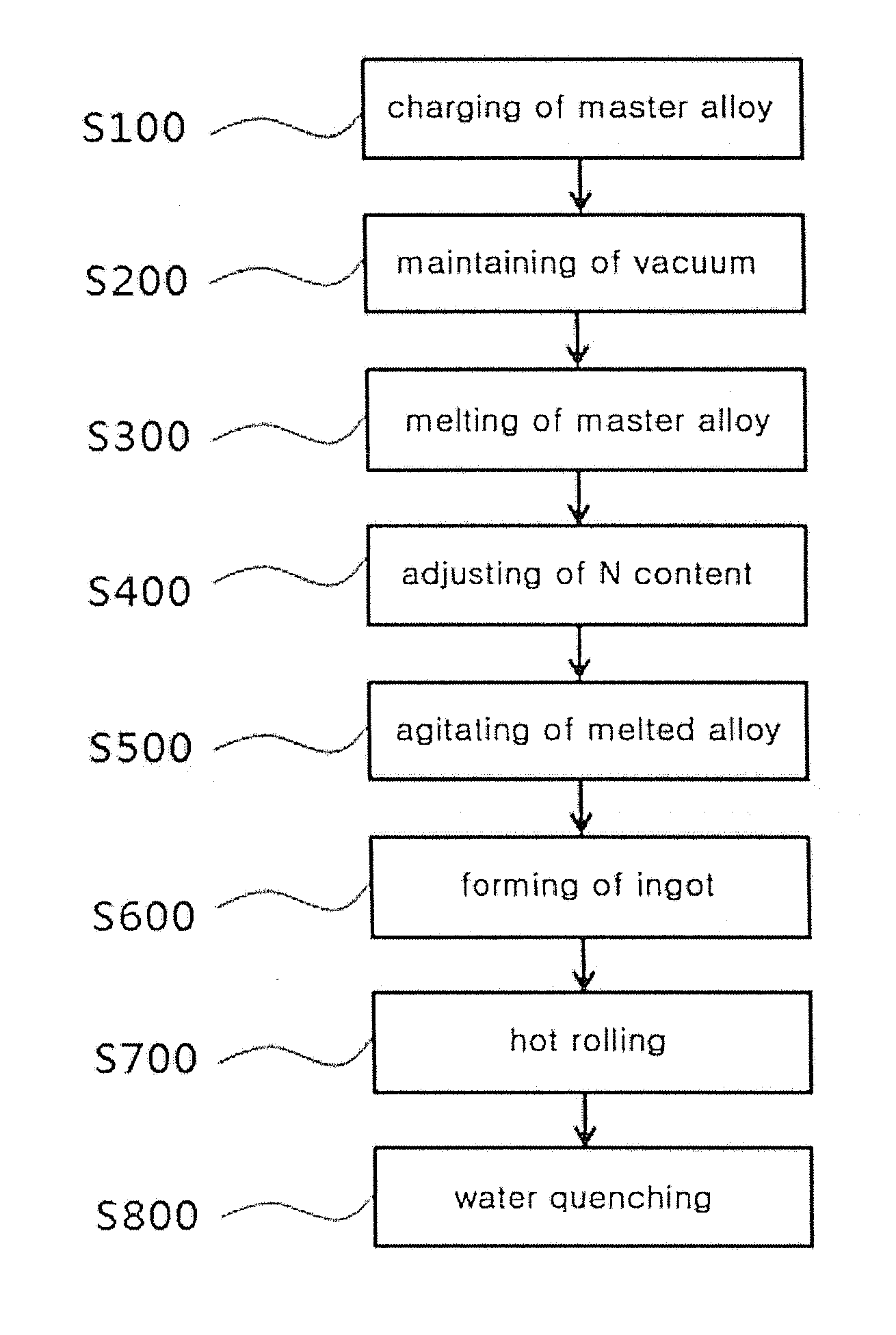

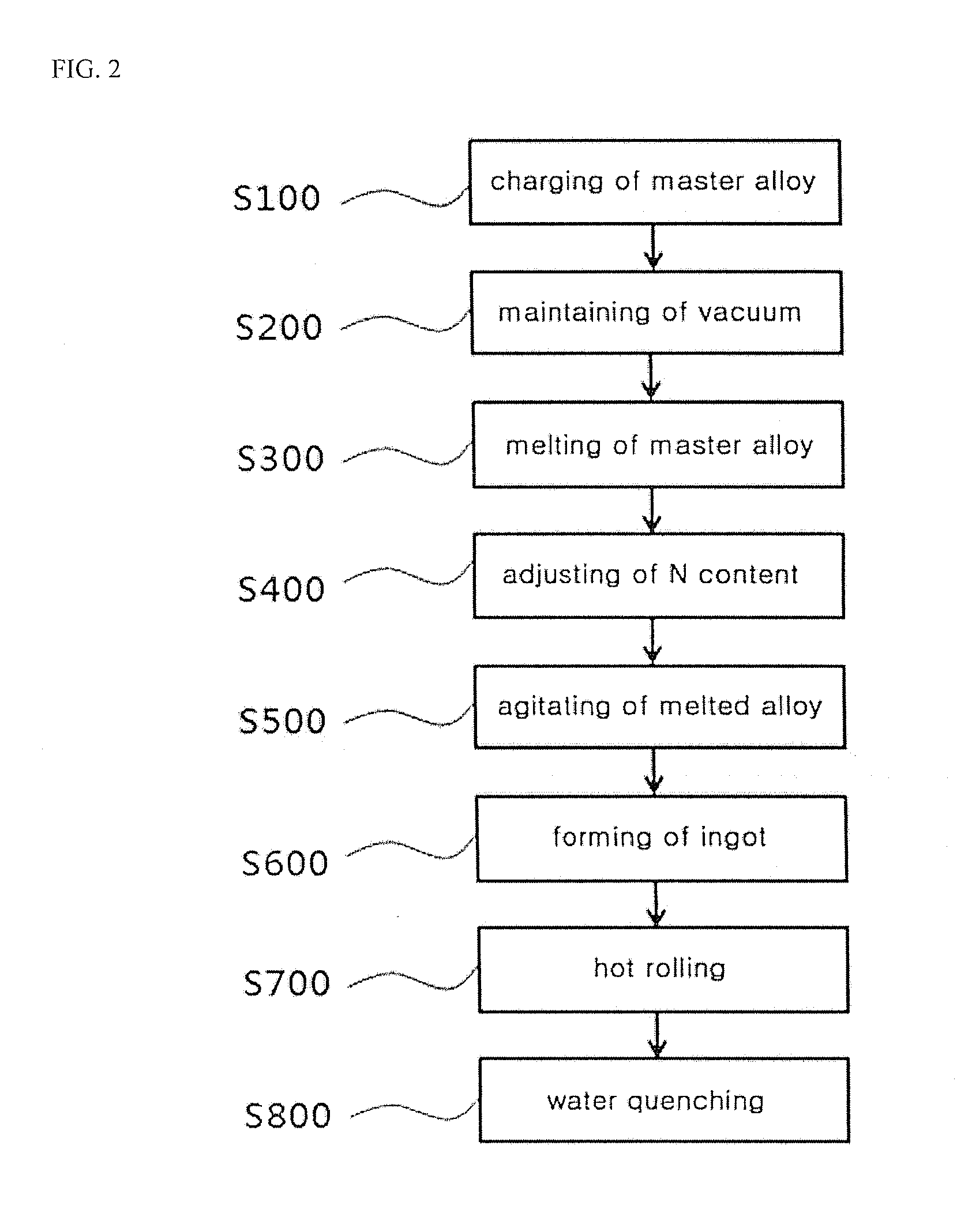

[0051]Referring to FIGS. 2 and 3, at the step of 5100, a master alloy consisting of Fe-50% Mn, Fe-60% Cr, pure iron, Fe-58.8% Cr-6.6% N for controlling the nitrogen (N) content, 75.1% Mn-17.4% Fe-6.8% C for controlling the carbon (C) content, tungsten (W) and / or molybdenum (Mo), was charged into a vacuum melting furnace. At the step of S200, the vacuum melting furnace was degassed until the vacuum level became 10−3 torr or below, and the vacuum leve...

experiment 1

Measurement of Tensile Properties

[0055]The tensile properties of the examples and the comparative examples fabricated according to the embodiments of the present invention are listed in table 2.

TABLE 2Yield strength Tensile strengthUniform Alloy(MPa)(Mpa)elongation (%)Ex. 152998062.1Ex. 255997346.3Ex. 353796052.3Ex. 449390359.3Ex. 552389951.1Ex. 652892749.4Ex. 747686855.7Ex. 853293050.8Comp. 120551540.0 (total elongation)Comp. 2205515 40.0 (total elongation)Comp. 3170480 40.4 (total elongation)Comp. 4533101962.8Comp. 550094059.0

[0056]As table 2 illustrates, compared to the commercial austenitic stainless steels of comparative examples 1 to 3 which exhibited the yield strength of 170˜205 MPa, the tensile strength of 480˜515 MPa, and the elongation of 40%, the examples fabricated according to the present invention exhibited superior mechanical properties, which were 476˜559 MPa of yield strength, 868˜980 MPa of tensile strength, and 46.3˜62.1% of uniform elongation.

[0057]Furthermore, ...

experiment 2

Measurement of Corrosion Resistance

[0059]In order to measure the corrosion resistance of the austenitic stainless steels according to the present invention, anodic polarization behavior of the sample was observed, as a result, the pitting potential was measured. Samples of austenitic stainless steels according to the examples of the present invention and comparative examples were immersed in a 1M NaCl solution at a room temperature, and the potential was increased at a potential scan rate (dV / dt) of 2 mV / s. The polarization responses are represented in FIG. 4 and the measured pitting potentials are listed in table 3.

TABLE 3AlloyPitting potentials (Epit), VSCE Ex 1No pitting (1.0 or above)Ex. 2No pitting (1.0 or above)Ex. 3No pitting (1.0 or above)Ex. 4No pitting (1.0 or above)Ex. 5No pitting (1.0 or above)Ex. 6No pitting (1.0 or above)Ex. 7No pitting (1.0 or above)Ex. 8No pitting (1.0 or above)Comp. 10.311Comp. 2 0.417Comp. 30.496Comp. 40.557Comp. 50.692

[0060]As illustrated in FIG. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Partial pressure | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com