Lattice matchable alloy for solar cells

a technology of solar cells and alloys, applied in the field of multijunction solar cells, can solve the problems of preventing effective photocarrier collection, wasting extra current, and not optimally combining structures, and achieve the effect of improving the performance of the disclosed solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

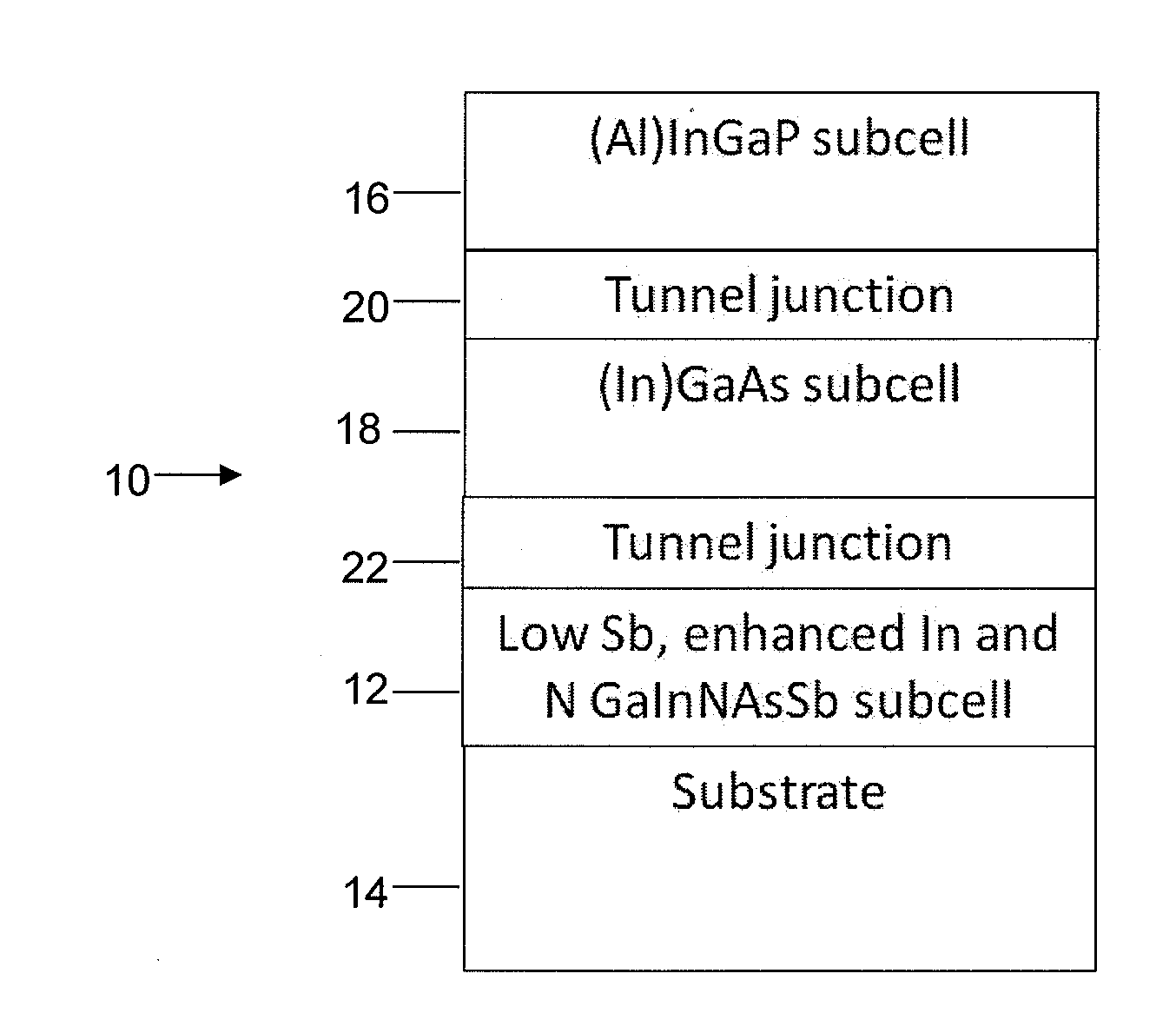

[0021]FIG. 1A is a schematic cross-section showing an example of a triple junction solar cell 10 according to the invention consisting essentially of a low Sb, enhanced In and N

[0022]GaInNAsSb subcell 12 adjacent the Ge, GaAs or otherwise compatible substrate 14 with a top subcell 16 of (Al)InGaP and a middle subcell 18 using (In)GaAs. Tunnel junction 20 is between subcells 16 and 18, while tunnel junction 22 is between subcells 18 and 12. Each of the subcells 12, 16, 18 comprises several associated layers, including front and back surface fields, an emitter and a base. The named subcell material (e.g., (In)GaAs) forms the base layer, and may or may not form the other layers.

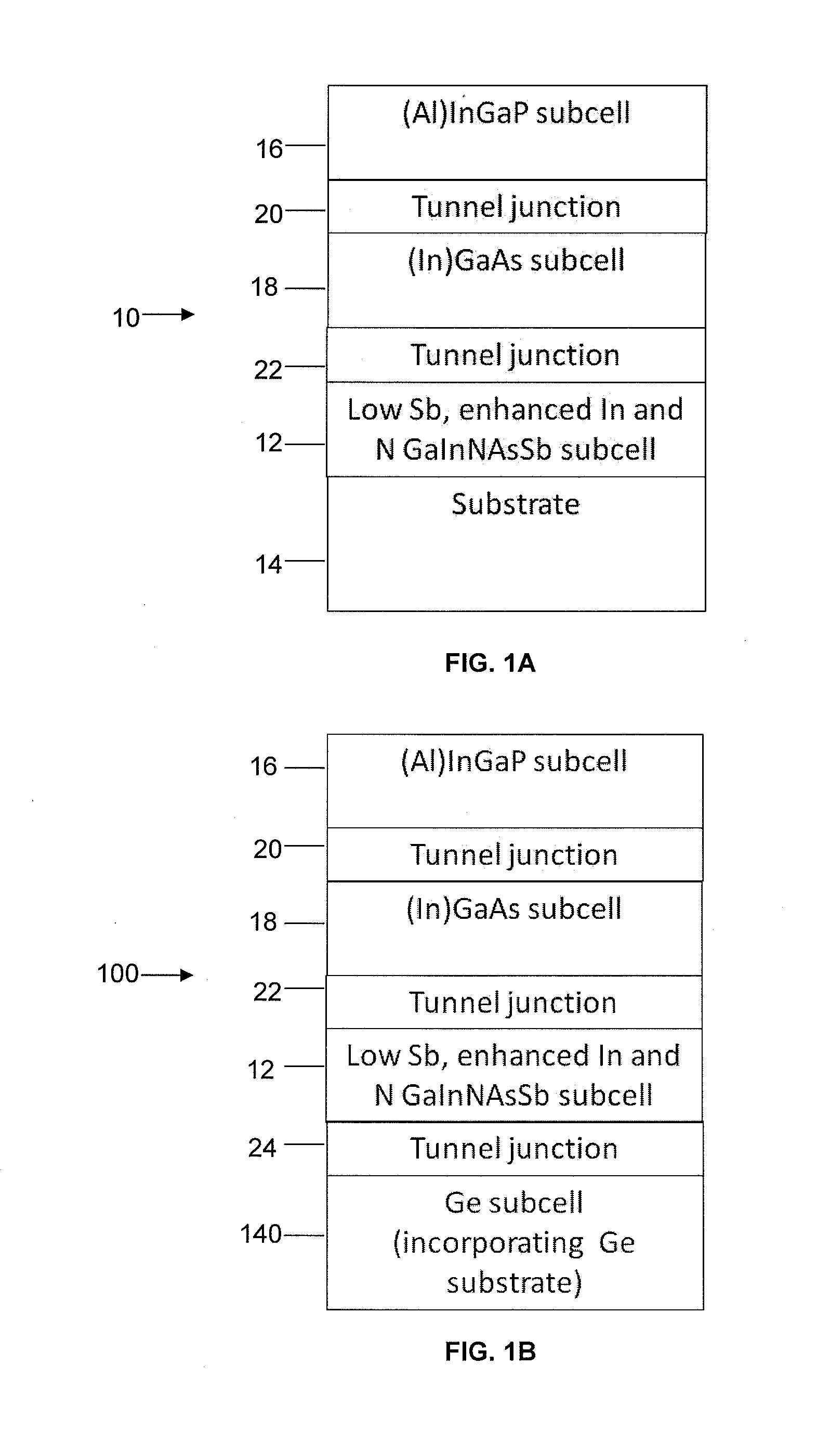

[0023]Low Sb, enhanced In and N GaInNAsSb subcells may also be incorporated into multijunction solar cells with four or more junctions without departing from the spirit and scope of the invention. FIG. 1B shows one such four-junction solar cell 100 with a specific low Sb, enhanced In and N GaInNAsSb subcell 12 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy | aaaaa | aaaaa |

| Lattice constant | aaaaa | aaaaa |

| Composition | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com