Biopharmaceutical plant in a column

a biopharmaceutical plant and column technology, applied in the field of biopharmaceutical plants in columns, can solve the problems of not being available on the market or described in the patent literatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

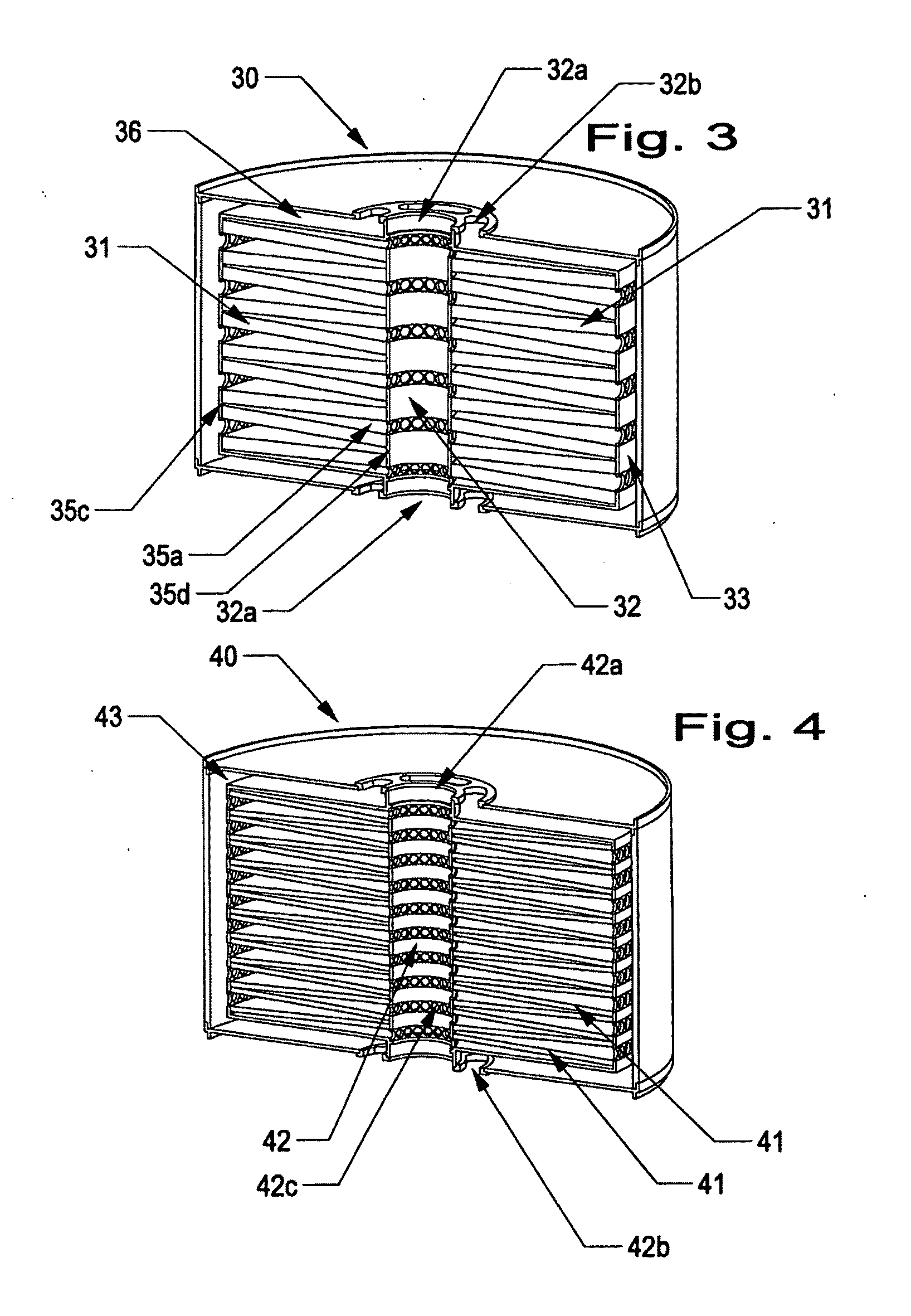

[0020]The present invention solves the problem of how to improve the flexibility of a bioreactor by providing a number of capsules serving different purposes for the bio-reaction taken place in the bioreactor. The capsules are easily assembled in a stack. By selecting a particular combination of different capsules stacked in a predetermined sequence, a bioreactor providing the optimal solution for producing a particular chemical compound is easily developed.

[0021]The present invention also solves the problem of how to optimize the size of the bioreactor by providing a reactor with increased “compactness”, which reduces the cost of manufacturing production facilities needed for industrial scale bio-fermentation.

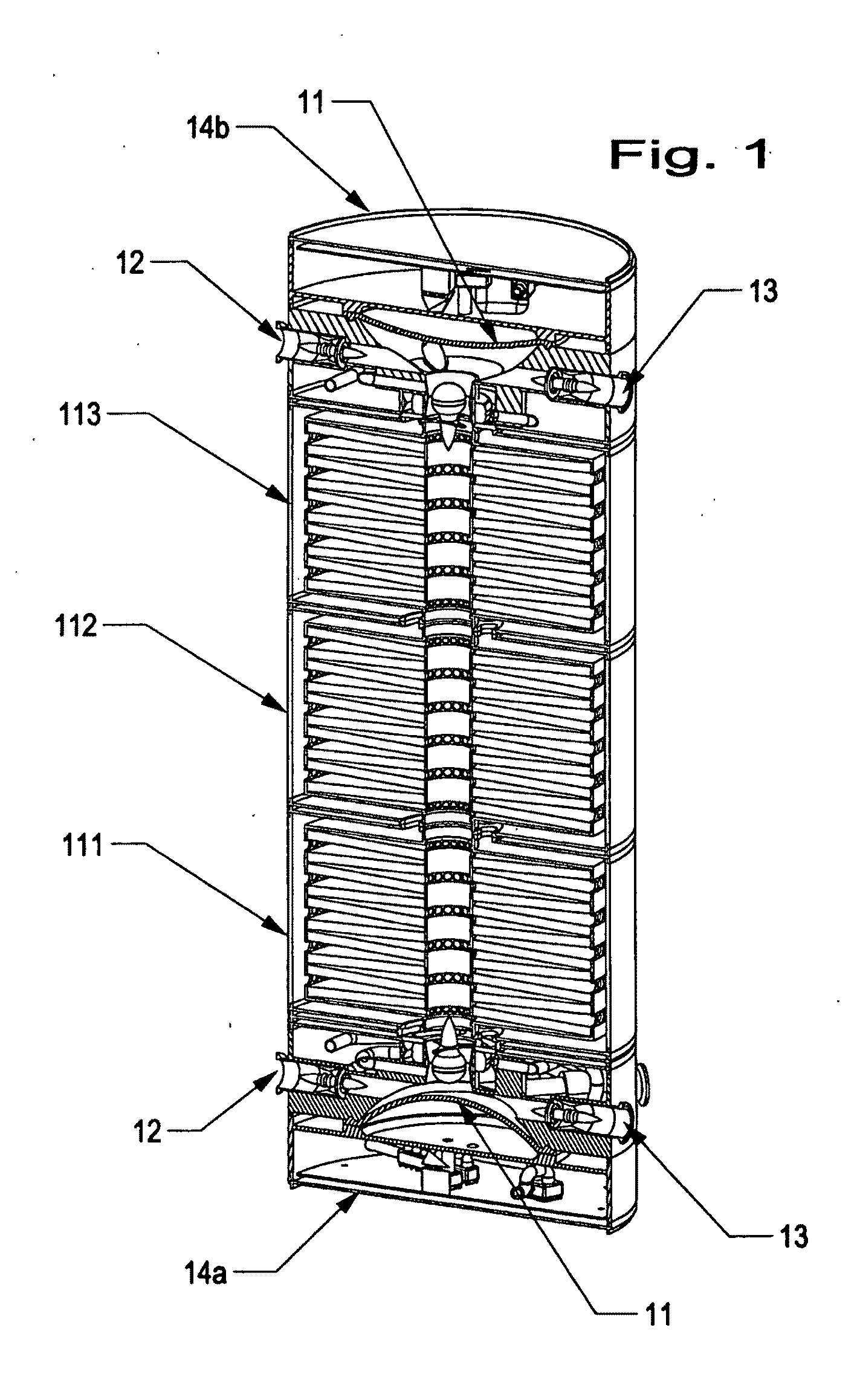

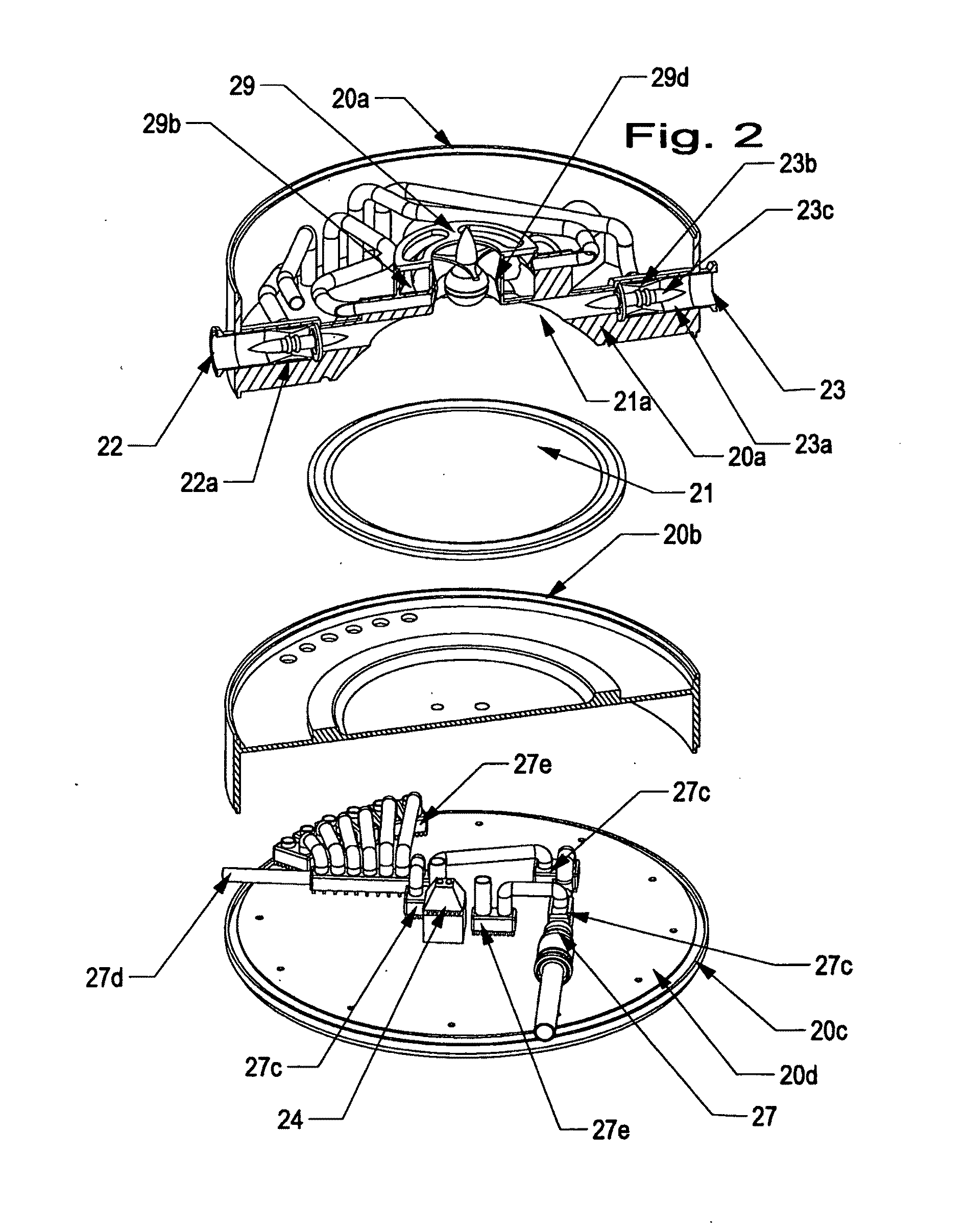

[0022]The invention is a single-use Biopharmaceutical Plant or bio factory assembled from a number of individual capsules and stacked into a column. The column operate on continues basis with in lifetime strictly opposite to the batch process. Such column comprises individual ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com