Multifunctional Periodic Cellular Solids and the Method of Making the Same

a multifunctional, periodic cellular solid technology, applied in the direction of hollow wall articles, other domestic articles, transportation and packaging, etc., can solve the problems of reducing relative density, degrading shear yield strength, and reducing the utility of load bearing structures, so as to improve improve the effect of structural properties and multifunctional design, and improve the repeatability of cell geometry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0118]Practice of the invention will be still more fully understood from the following examples, which are present herein for illustration only and should not be construed as limiting the invention in anyway.

Example

Truss and Core Sandwich Panel

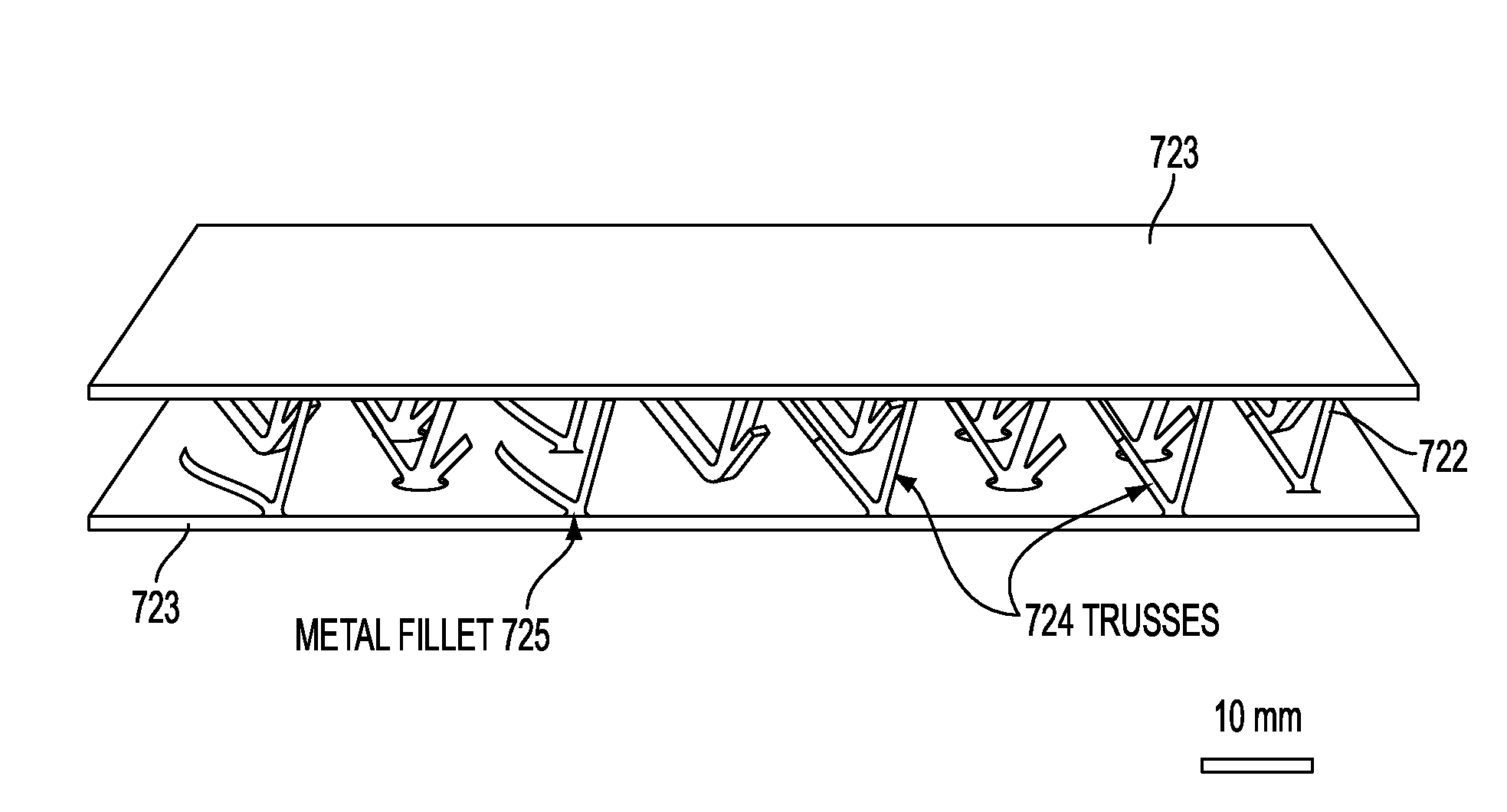

[0119]FIGS. 19(A) and 19 (B) shows the apparatus 720 for an exemplary process to be used to fabricate sheets 720 of miniature wrought metal trusses from a perforated metal sheet (hexagonal perforations). The hexagonal perforated 304 stainless steel sheet was obtained (Woven Metal Products, Alvin, Tex.). It was 0.028″ thick and contained 7 / 16″ hexagonal perforations of ½″ staggered centers spacing. The open area percentage was approximately 81%. The perforated sheet was first annealed in vacuum at 1100° C. and then stretched at its intersections using dowel pins within a die of the apparatus 720.

[0120]FIGS. 20(A)-(D) are photographic depictions of the resultant three dimensional layer 722, showing the side view, first perspective view, second p...

example

Honeycomb Versus Tetrahedral

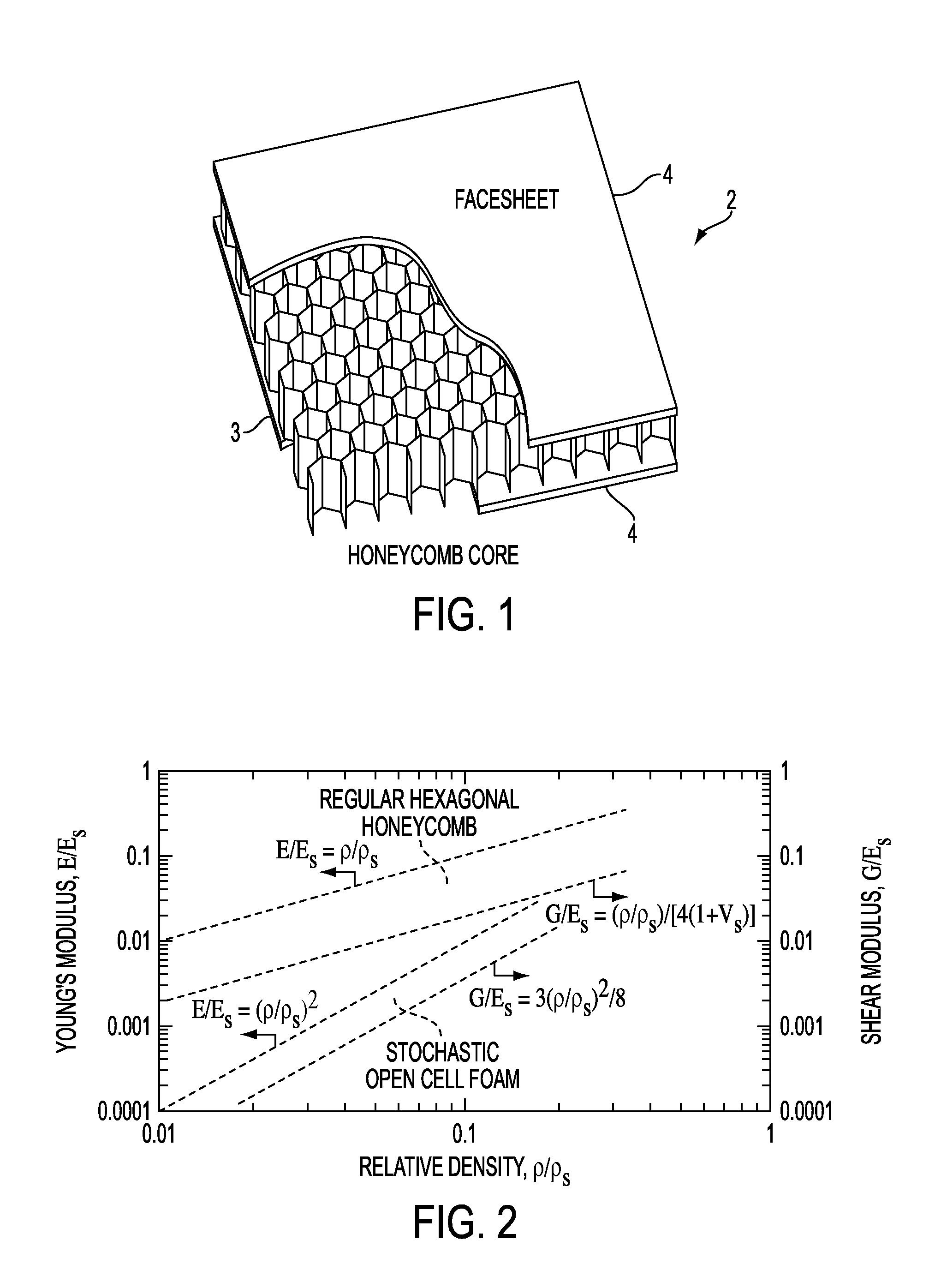

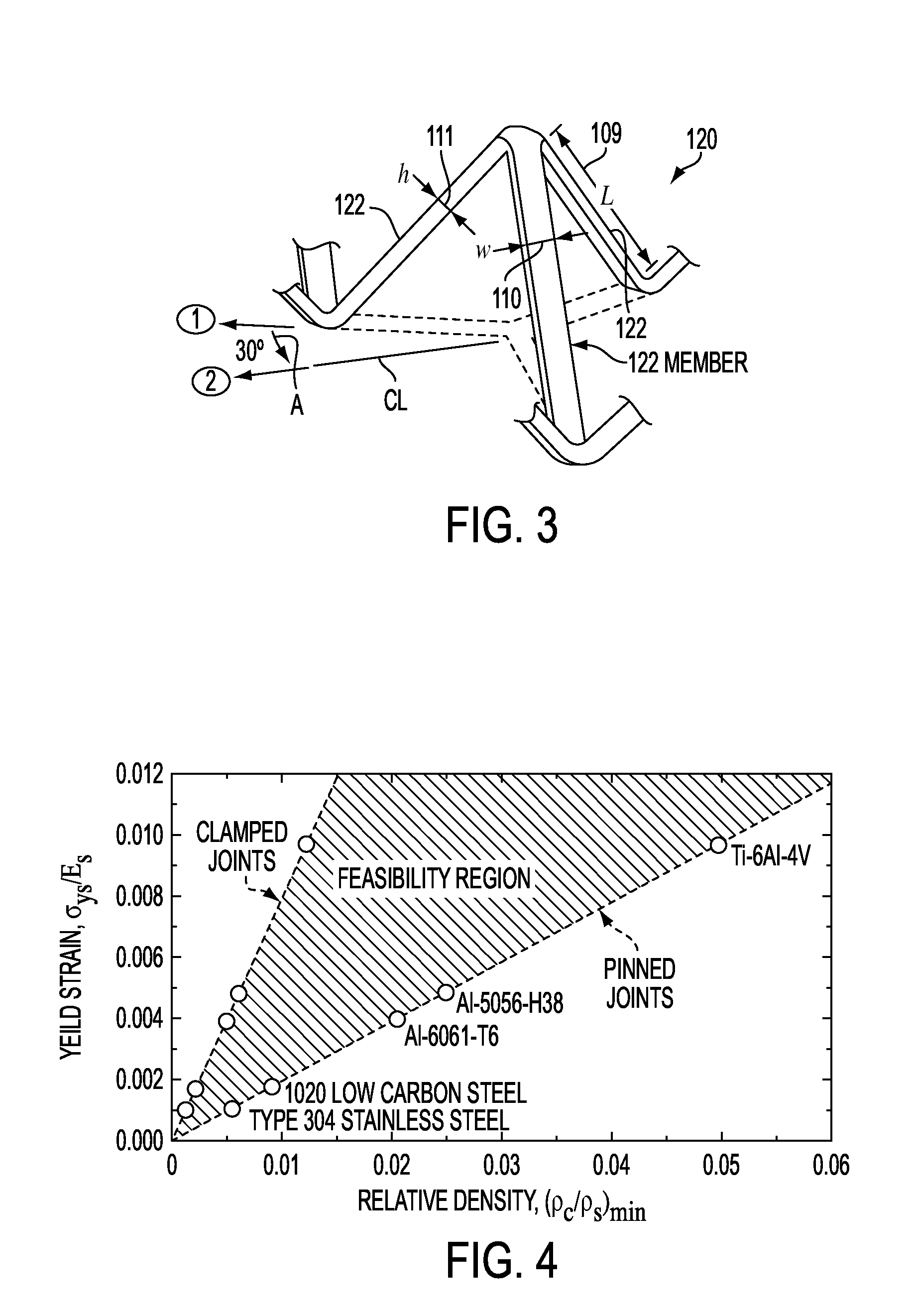

[0138]As graphically shown in FIG. 9, Hexcel Composites (Pleasanton, Calif.) 5056-H39 aluminum honeycomb shear properties (plate shear test data) [2] are compared with measurements for the type 304 stainless steel tetrahedral truss core and model predictions, Eqs. (3) and (5). The honeycomb is normally made from rolled alloy 5056-H191 aluminum sheet (Es=71 GPa, σys=435 MPa and ρs=2.6 g / cm3) onto which adhesive lines are drawn. This is followed by stacking, curing to form HOBE®(Honeycomb Before Expansion) block and then expansion into honeycomb [2]. There is a doubling of wall thickness in the “L” direction as opposed to the other “W” direction and the mechanical properties are affected. In FIG. 9, it can be seen that the measured and predicted relative shear modulus and strength of the tetrahedral truss core compare favorably with those of similar relative density honeycomb. Note however, that predictions for the truss core shear modulus are based upon pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com