Electrostatic precipitator pre-filter for electrohydrodynamic fluid mover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

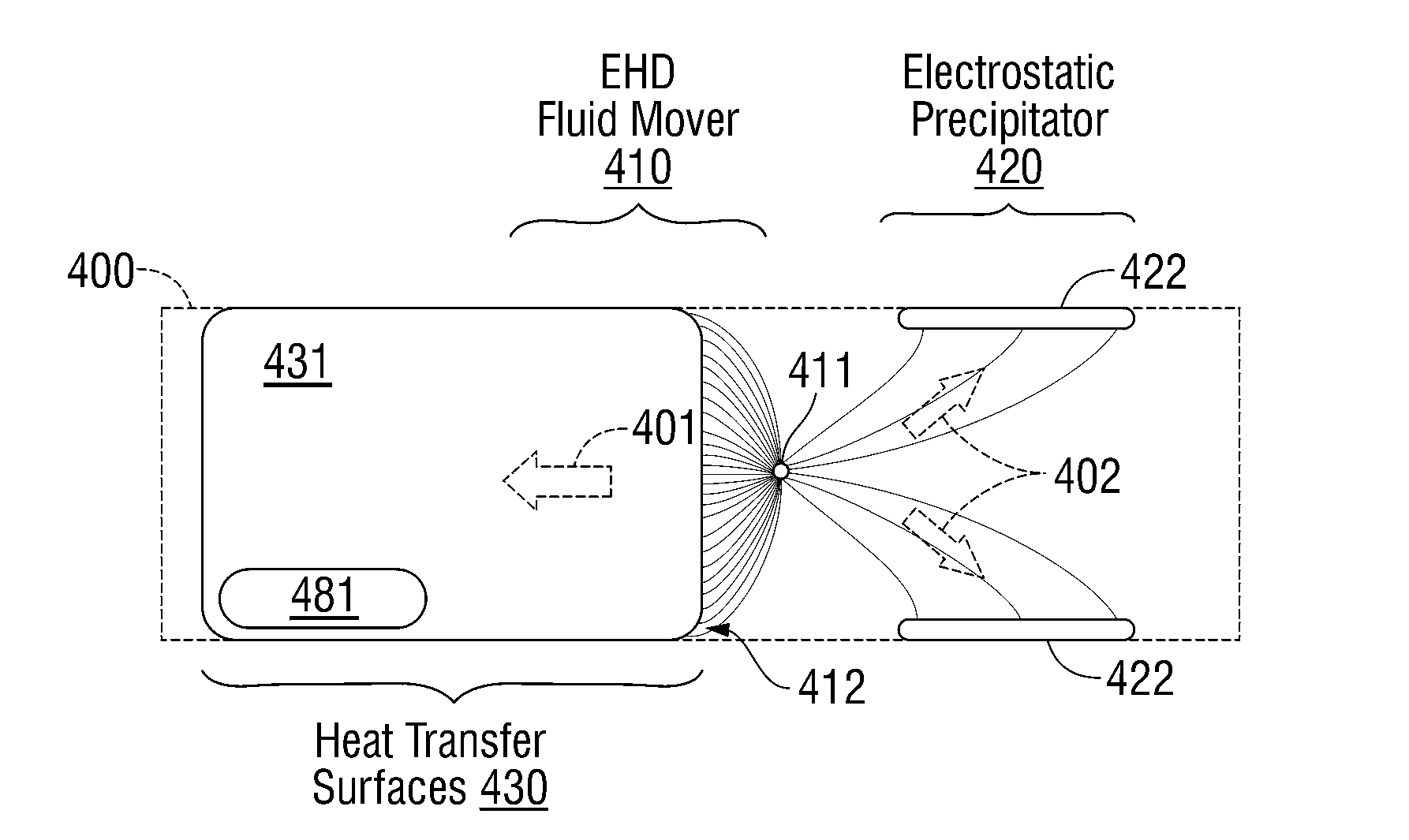

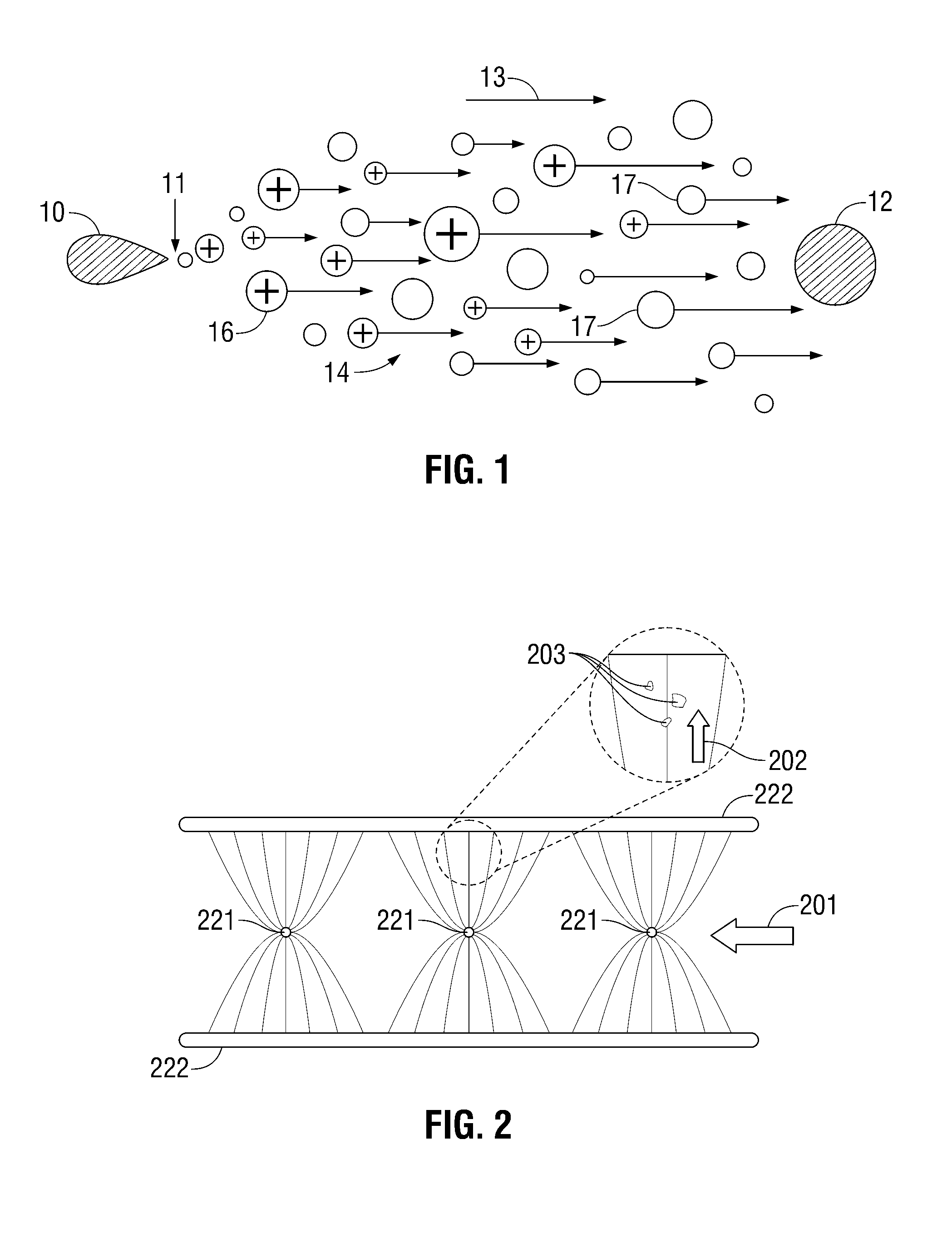

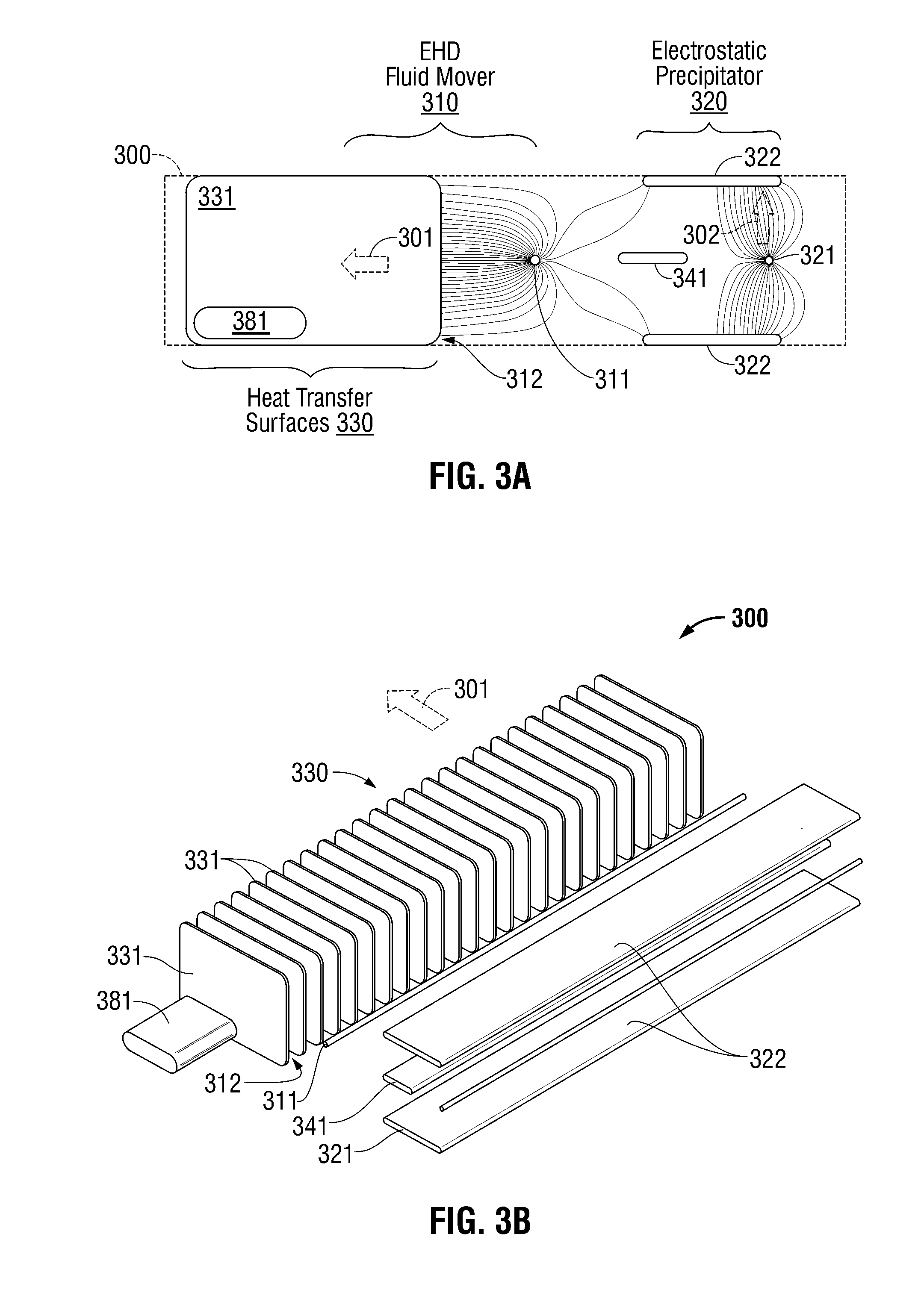

[0041]Some embodiments of thermal management systems described herein employ EHD fluid mover devices to motivate flow of a fluid, typically air, based on acceleration of ions generated as a result of corona discharge. Likewise, ions generated by corona discharge are also used in some embodiments to charge entrained particulates and electrostatically precipitate them from the fluid (e.g., air) flow. Other embodiments may employ other ion generation mechanisms for either or both of the EHD fluid motivation and electrostatic precipitation and will nonetheless be understood in the descriptive context herein which emphasizes corona discharge as an illustrative mechanism. In each case, electrostatic precipitation is performed upstream of collector electrode surfaces toward which a downstream EHD fluid mover accelerates fluid flow. In this way, the upstream electrostatic precipitator acts as a pre-filter (with low flow-impedance) and can at least reduce accumulation of otherwise detrimenta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com