Process for the preparation of sevelamer

a technology of sevelamer and process, which is applied in the field of process for the preparation of sevelamer, can solve the problems of laborious and laborious further reaction steps, entail substantial costs at industrial level, and produce a highly congealed and viscous reaction mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

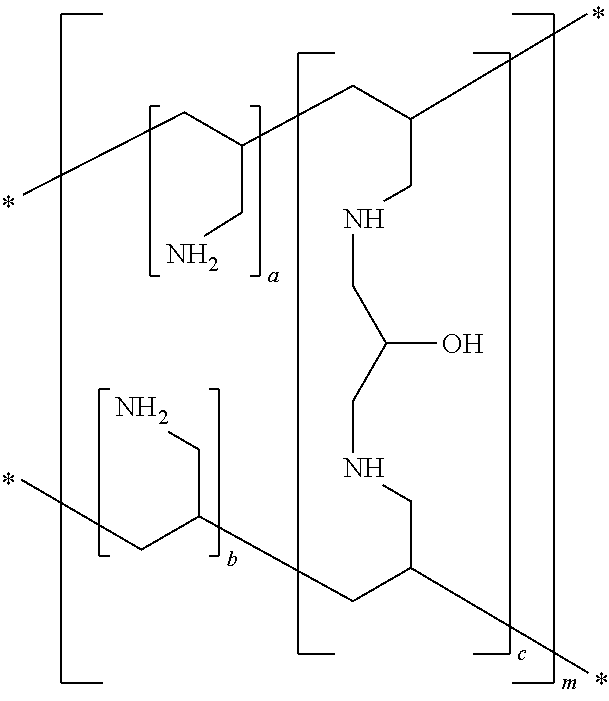

Image

Examples

example 1

Sevelamer Preparation

Loads

[0041]

PAASolutionPAAPAA (molHClwashing14.0%100%allylamineepichlorohydrinepichlorohydrinHCl38.2%isopropanol(g)(g)units)(mol)(g)(mol)(g)(g)16650234441.14.6426.511.9113714630

[0042]A conventional reactor, with blade stirrer, is used. HCl is added to the polyallylamine loaded into the reactor in two batches dosed at a distance of 15 minutes. When the temperature reaches around 25° C., dosing of epichlorohydrin begins and continues for around 10 minutes. After 45 minutes, heating to 78° C.-83° C. begins and continues for 3 hours, at the end of which the product, after cooling to room temperature, is washed with isopropanol. Washing is performed by maintaining the product under stirring with isopropanol for 1 hour, then the product is centrifuged and vacuum dried at 60° C. for 3 hours, finally obtaining 2.94 kg of product in the form of a whitish solid.

example 2

Sevelamer Preparation

[0043]The same procedure as described in example 1 is followed, but isopropanol is not added and the reaction mixture is instead maintained at 20-25° C. for three hours. The final product is isolated by filtration.

Properties of the Sevelamer Obtained

[0044]

Swell index12.5 Phosphate binding capacity (mmol / g) 5.8 Chloride content (weight / weight)18.5%Epichlorohydrinnot detectable (

[0045]The analytical evaluations are performed according to methods known in the art and conventionally used for sevelamer.

example 3

Sevelamer Carbonate / Bicarbonate Preparation

[0049]1.4 kg of water is loaded into a 2 litre glass reactor. The temperature is set to 35° C. and 100 g of sevelamer hydrochloride is added in portions, stirring the mixture. A solution of 30% sodium hydroxide is then added until pH 12 is reached (around 71 g) and gaseous carbon dioxide is bubbled through. The temperature is maintained at 35-37° C. until pH 7.2 is reached. The mixture is maintained at 35° C. under stirring for 2 hours and if necessary further carbon dioxide is bubbled through until the pH is stabilized at 7.2. The suspension is filtered, the solid washed repeatedly with water to eliminate as much of the residual chlorine as possible. The solid thus obtained is dried and ground.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar ratio | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com