Miniaturized Spring Contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

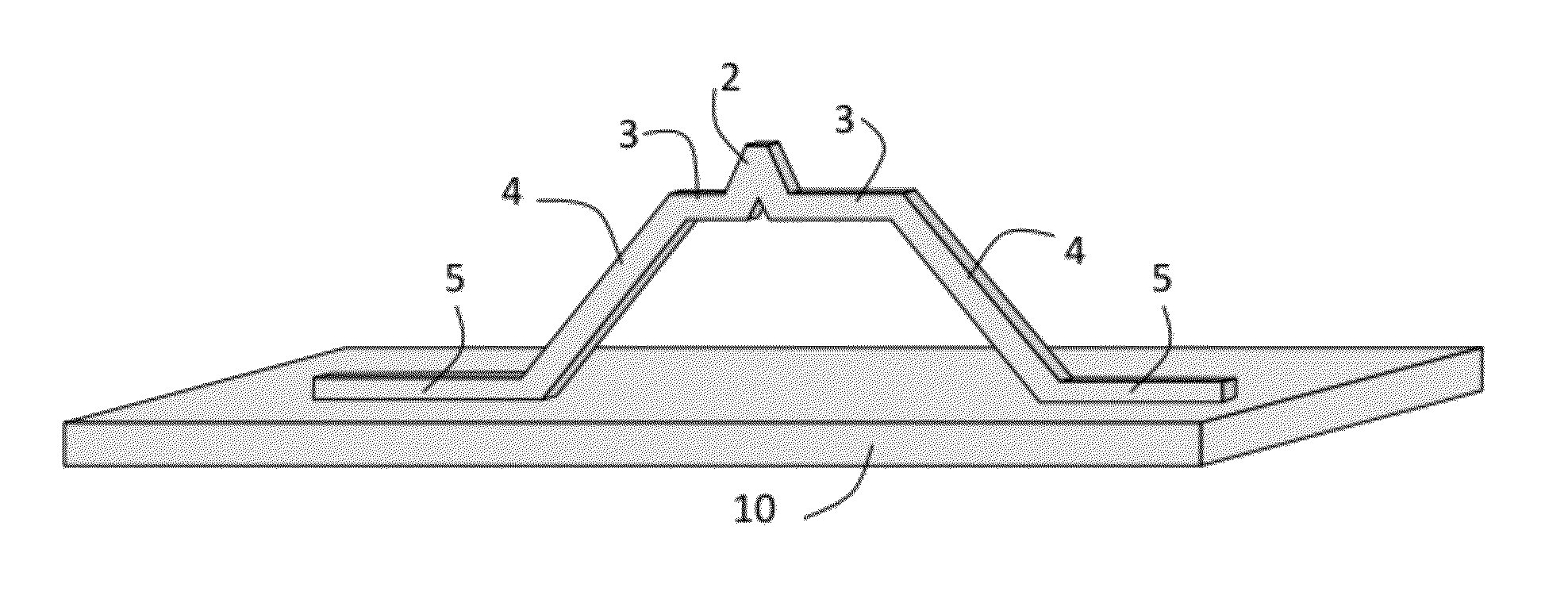

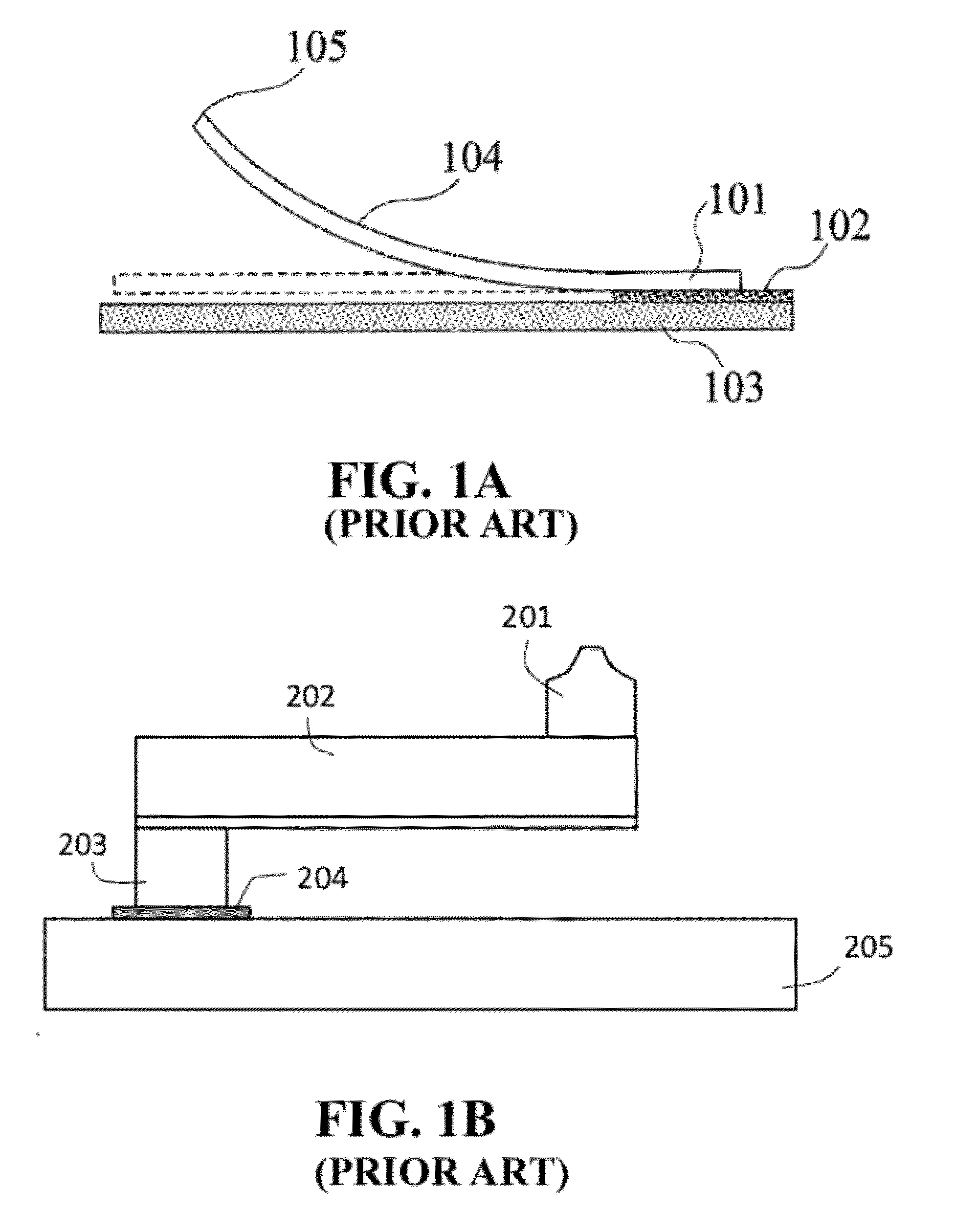

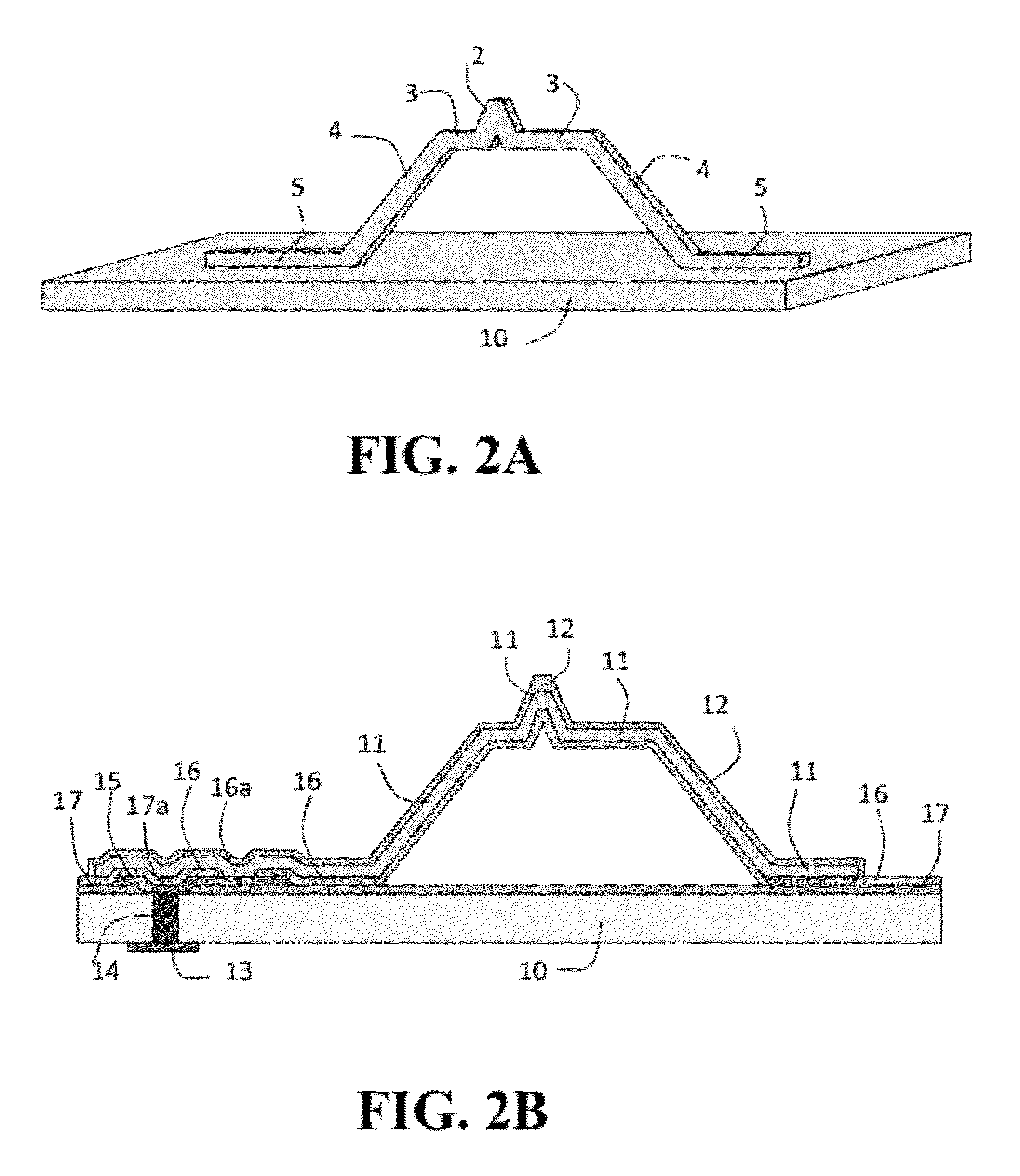

[0028]The following detailed description is directed to certain specific embodiments of the invention. In the description, reference is made to the drawings wherein like parts may be assigned with like numerals throughout. Also, for ease of description, the dimensions of the parts are not to the scale. Because of this, important dimensions are given in values throughout the whole description of the embodiments.

[0029]The present invention provides a spring contact that possesses pre-determined mechanical strength and electric conductivity. Normally, at non-operational state, a spring contact is at un-stressed condition and no deformation is created; in the situation that the spring contact is pressed against the testing pad of a semiconductor device on a semiconductor wafer, the spring contact elastically deforms, and this deformation provides certain required force to make a good mechanical contact to the testing pad. Once a stable mechanical and electrical contact to the testing pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com