Pretreatment of fats and oils in the production of biofuels

a technology of biofuels and fats, applied in the direction of biofuels, fatty-oils/fat refining, fuels, etc., can solve the problems of shortening the useful life of feedstocks, reducing the ability to catalytically convert them into hydrocarbons, and so as to reduce the activity of hydroprocessing and shorten the useful life , the effect of increasing the overall cost of biofuel production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

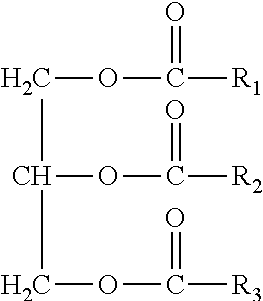

Image

Examples

example

[0032]A representative plant oil, namely camelina oil, as a feedstock for biofuel production, was analyzed for trace metals by inductively coupled plasma atomic emission spectrometry (ICP-AES). Three jars were then filled with 100 ml each of this feedstock, and 10 g of a different ion exchange resin was added to each jar. In particular, these resins were (1) a strong base anion exchange resin having quaternary ammonium functional groups in the hydroxide form, (2) a weak base anion exchange resin having amine functional groups, and (3) a strong acid cation exchange resin having sulfonic acid functional groups in the hydrogen form. The jars containing resin and camelina oil were subsequently sealed and shaken manually for 5 seconds, before being placed onto a mechanical shaker. After 3 days of mechanical shaking, the resulting, treated oil samples were filtered from the resins and submitted for the same ICP-AES analysis. The feedstock analyses, both prior to and after treatment, as we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com