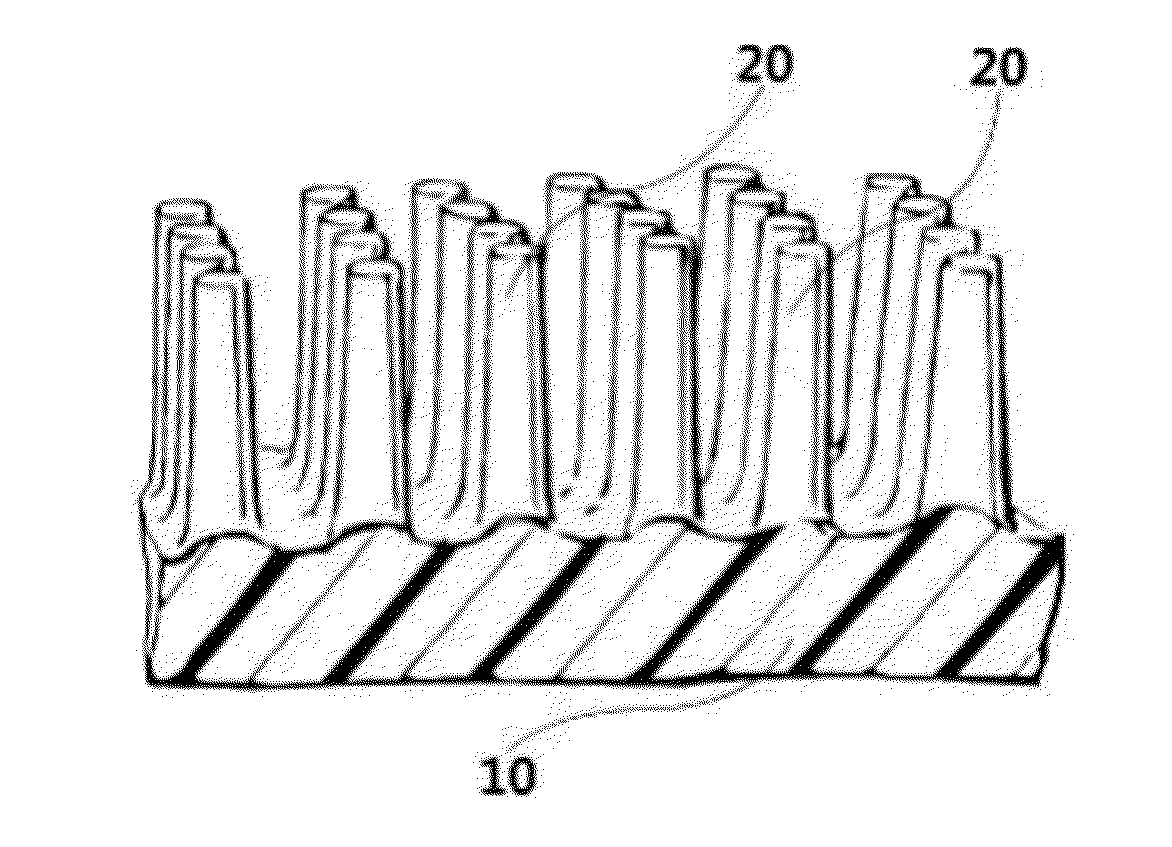

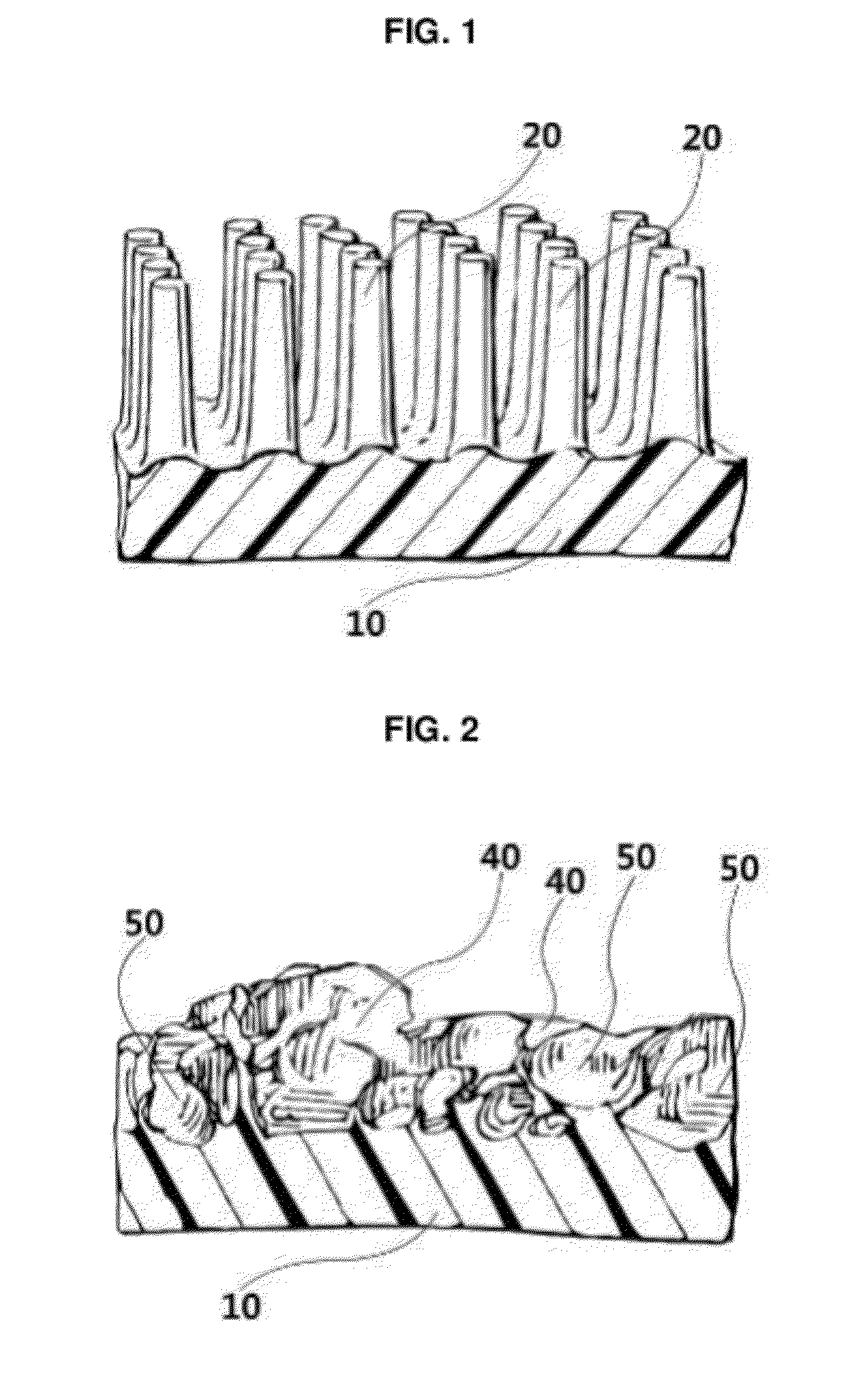

Artificial breast implant provided on the surface threof with silicon open cell foam layer, and method for producing the same

a technology of open cell foam and artificial breast, which is applied in the field of artificial breast implants, can solve the problems of inferior durability of the shell of the artificial breast prosthesis, significant deterioration of the saline filled artificial breast prosthesis after surgery, and the inability to manufacture the same, so as to prevent the occurrence of stress concentration and ensure the effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

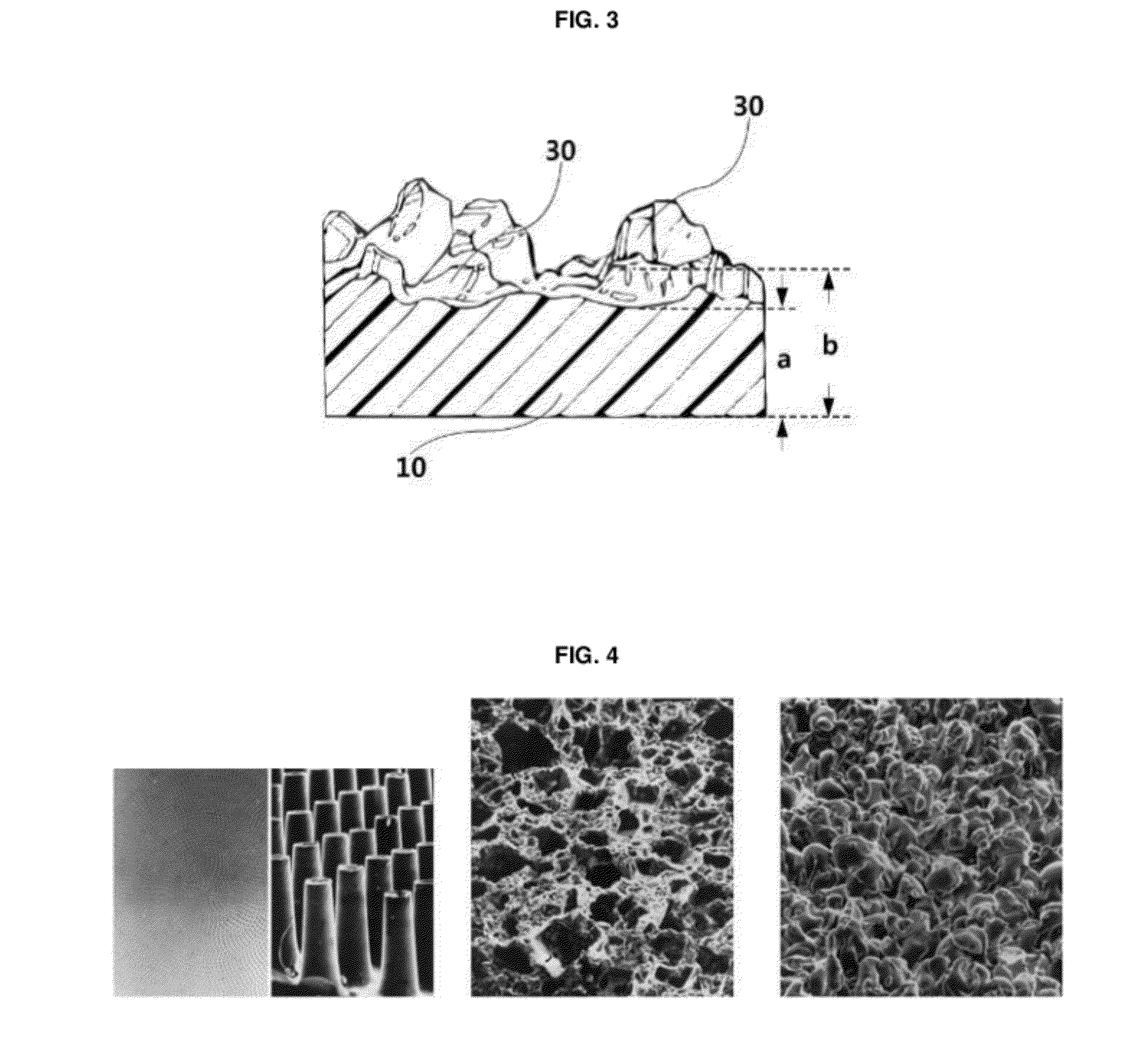

[0086]First, methyl hydrogen siloxane; dimethylsiloxane containing a small amount of platinum catalyst, containing about 20% of a silica filler and having a molecular weight of 50,000 to 100,000 ten thousands; and dimethyl vinyl siloxane containing dimethylvinyl terminated siloxane having a dimethyl group as a terminal group, containing 20% of a silica filler and having a molecular weight of 50,000 to 100,000 ten thousands were sufficiently mixed at an equivalent ratio of methyl hydrogen siloxane to prepare a silicone material.

[0087]Xylene as an organic solvent was added to the silicone material silicone such that the concentration of the silicone was 35 wt %, followed by thoroughly mixing to prepare a silicone dilute solution.

[0088]Then, a breast-shaped mold for artificial breast shell was treated and coated with the silicone dilute solution by dipping, the organic solvent was completely evaporated at 50° C. in an oven, the mold was dried, and the dried artificial breast mold provi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com