Light emitting element, light source device, and projection display device

a technology of light source device and light emitting element, which is applied in the direction of instruments, semiconductor devices, projectors, etc., can solve the problems of low literature 1 has drawbacks, and the emission angle of light that is emitted from the light emitting element cannot be narrowed to less than 15°, so as to improve the directivity of emission light, the effect of high luminance and improved directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

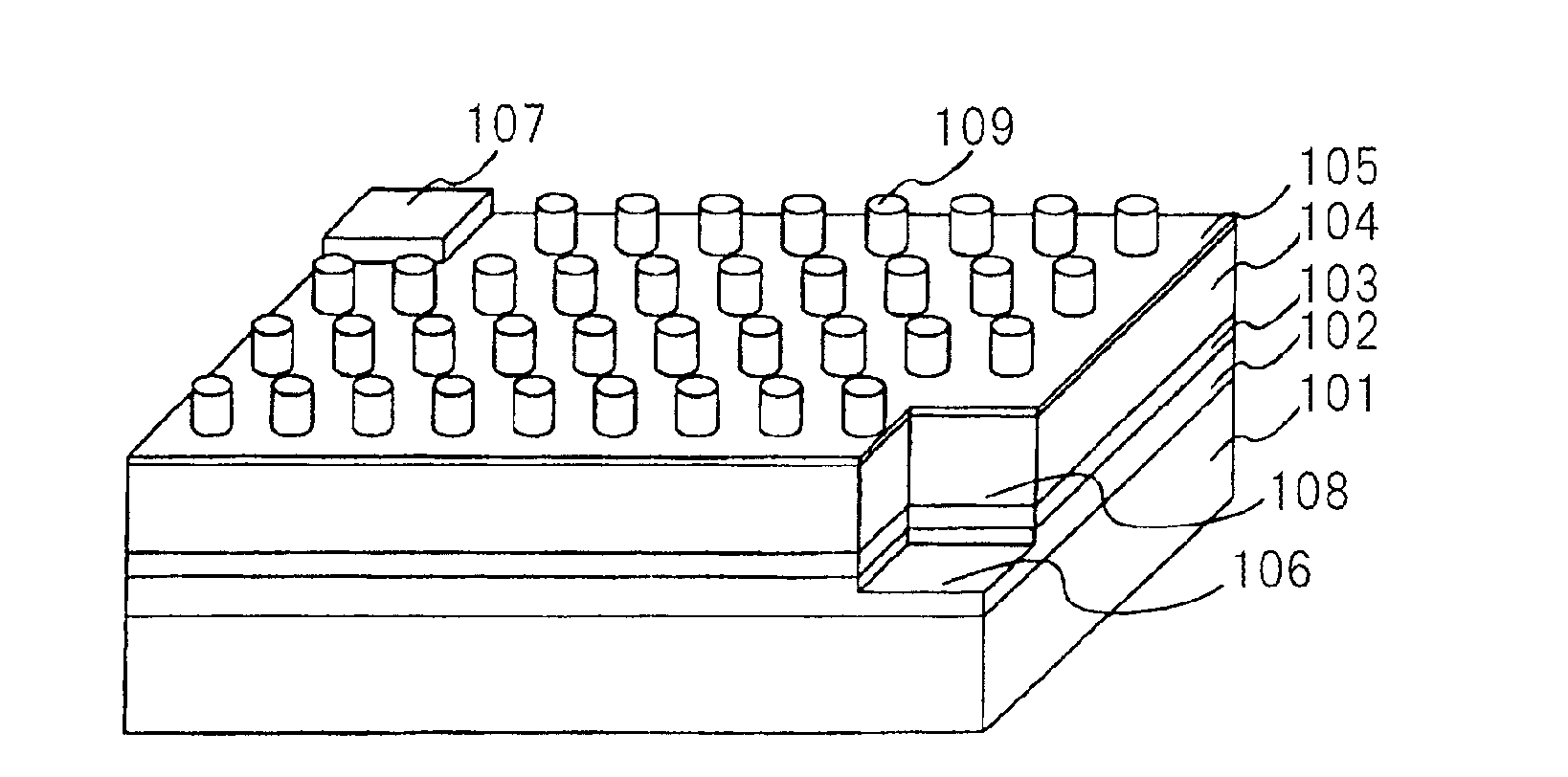

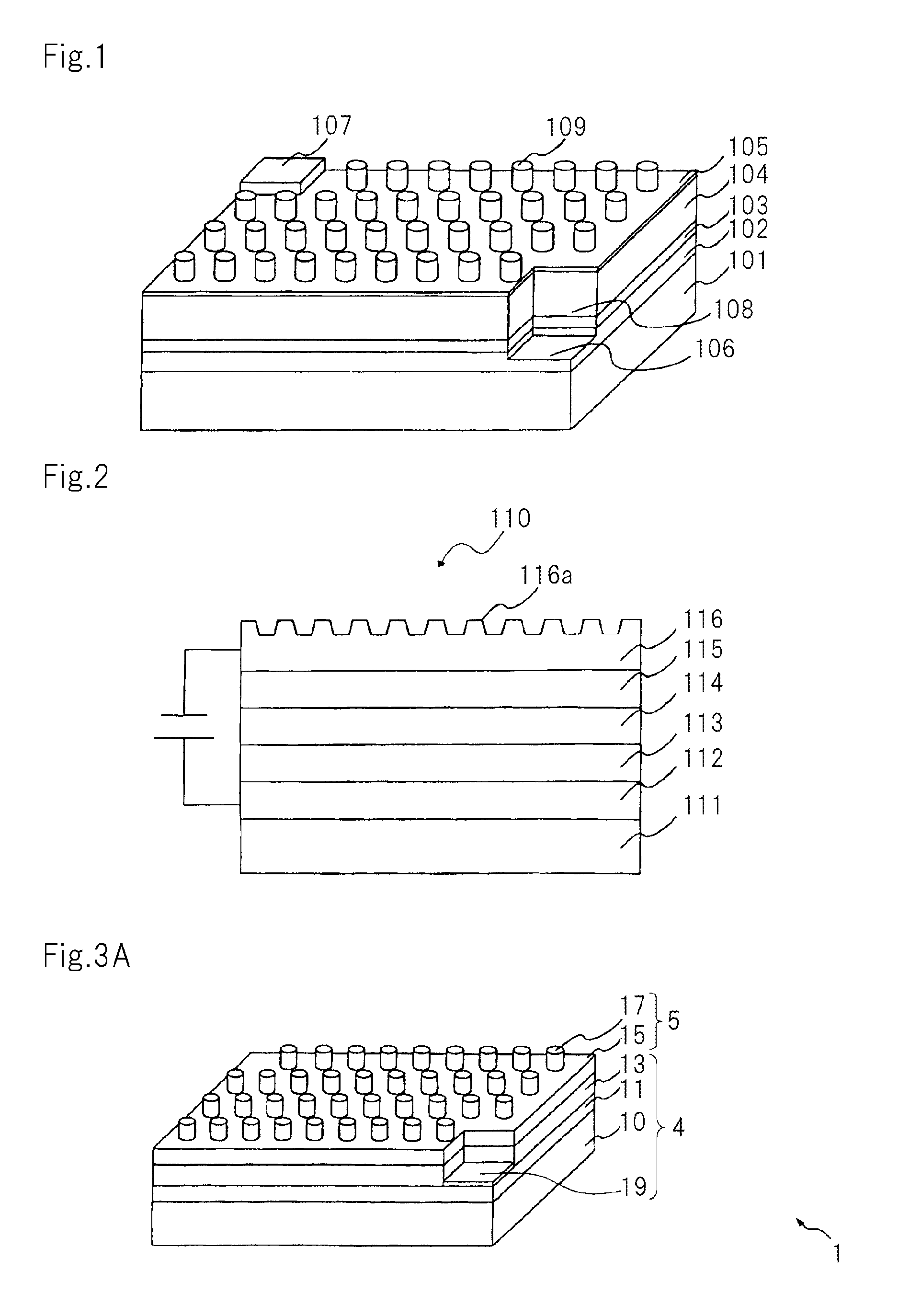

[0054]FIG. 3A is a perspective view schematically showing the structure of a light emitting element according to a first embodiment of the present invention. FIG. 3B is a plan view schematically showing the light emitting element according to this embodiment. Since the individual layers of the light emitting element are very thin and their thickness largely differ, it is difficult to illustrate the individual layers in the exact scales. Thus, the drawings do not illustrate the individual layers in the exact scales, but schematically illustrate them.

[0055]As shown in FIG. 3A, light emitting element 1 according to the first embodiment has light source layer 4 and directivity controlling layer 5 that is stacked on light source layer 4 and that operates as an optical element layer into which light emitted from light source layer 4 enters.

[0056]Light source layer 4 has substrate 10 and a pair of hole transport layer 11 and electron transport layer 13 that are formed on substrate 10. Stac...

second embodiment

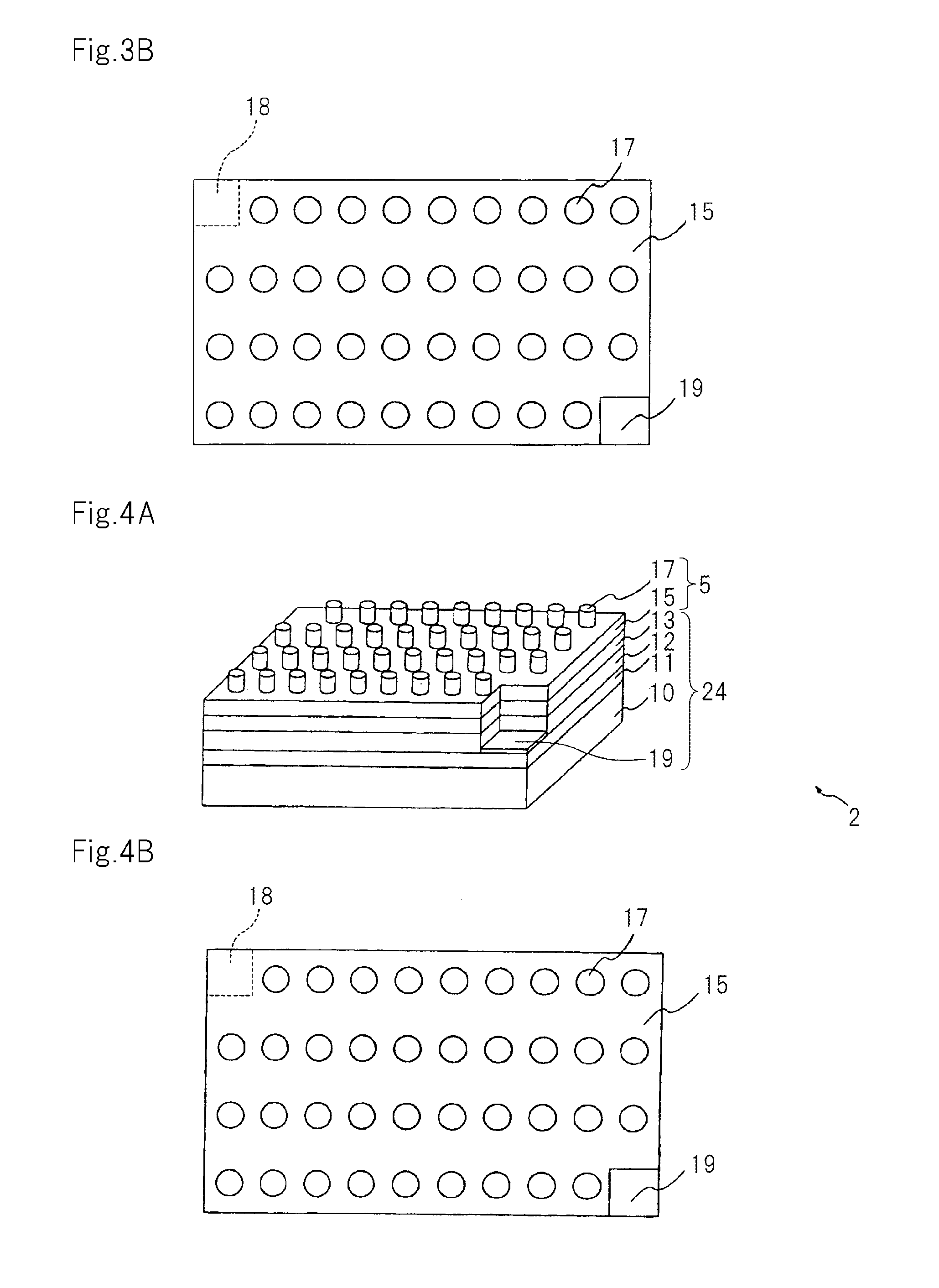

[0085]FIG. 4A is a perspective view schematically showing a light emitting element according to a second embodiment of the present invention. FIG. 4B is a plan view schematically showing the light emitting element according to the second embodiment.

[0086]As shown in FIG. 4A and FIG. 4B, light emitting element 2 according to the second embodiment has light source layer 24 and directivity controlling layer 5 that is stacked on light source layer 24 and into which light emitted from light source layer 24 enters. Since directivity controlling layer 5 of light emitting element 2 according to the second embodiment is the same as that according to the first embodiment, the description of directivity controlling layer 5 will be omitted. Light source layer 24 of light emitting element 2 according to the second embodiment is different from light source layer 4 according to the first embodiment only in that active layer 12 is formed between hole transport layer 11 and electron transport layer ...

third embodiment

[0094]FIG. 6A is a perspective view schematically showing a light emitting element according to a third embodiment of the present invention. FIG. 6B is a plan view schematically showing the light emitting element according to the third embodiment.

[0095]As shown in FIG. 6A and FIG. 6B, light emitting element 3 according to the third embodiment has light source layer 34 and directivity controlling layer 5 that is stacked on light source layer 34 and into which light emitted from light source layer 34 enters. Since directivity controlling layer 5 of light emitting element 3 according to the third embodiment is the same as that according to the firth embodiment, the description of directivity controlling layer 5 will be omitted. Light source layer 34 of light emitting element 3 according to the third embodiment is different from light source layer 24 according to the second embodiment in that anode layer 29, that is an anode, is formed completely between substrate 10 and hole transport ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com