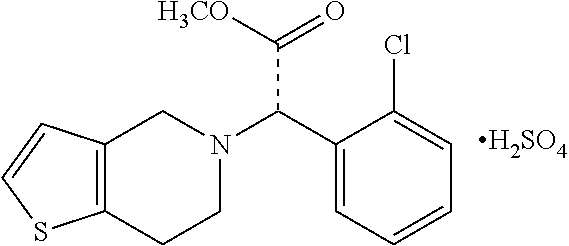

Preparation Method Of The Solid Formulation Of Clopidogrel Bisulfate

a technology of clopidogrel and bisulfate, which is applied in the field of preparation of clopidogrel bisulfate tablets, can solve the problems of poor final product quality and sticking problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

preparing Clopidogrel Bisulfate Tablets

[0064]97.88 g Clopidogrel bisulfate was mixed with 60.0 g Lactose, 40.00 g Microsrystalline Cellulose. Adding the 10% prepared Hydroxypropyl Cellulose solution and granulation. The granules were dried and screening. Blending with 26.00 g Microcrystalline Cellulose, 6.00 g Crospovidone, 17.00 g of Hydrogenated Vegetable Oil and Sodium Lauryl Sulphate and compression. The tablet weight is 250 mg with diameter 9 mm.

example 2

[0065]97.88 g Clopidogrel bisulfate was mixed with 60.00 g Lactose, 40 g of Microcrystalline Cellulose. Adding the 10% prepared Hydroxypropyl Cellulose solution and granulation. The granules were dried and blended with Aerosil (1.5 g, the weight equivalent to 0.6% of tablet weight), Microcrystalline Cellulose 26.00 g, Crospovidone 6.00 g, 17.00 g Hydrogenated Vegetable Oil and Sodium Lauryl Sulphate. Then compression with tablet weight 250 mg and diameter 9 mm.

example 3

[0066]97.88 g Clopidogrel bisulfate was premixed with Aerosil, (0.75 g, equivalent to 0.3% of tablet weight), then mixed with Lactose 60.00 g, Microcrystalline Cellulose 40.00 g. Adding the 10% prepared Hydroxypropyl Cellulose solution to and granulation. The granules were dried and blended with Microcrystalline Cellulose 26.00 g, Crospovidone 6.00 g, 17.00 g Hydrogenated Vegetable Oil and Sodium Lauryl Sulphate. Then compression with tablet weight 250 mg with diameter 9 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com