Three Stage Combustor For Low Quality Fuels

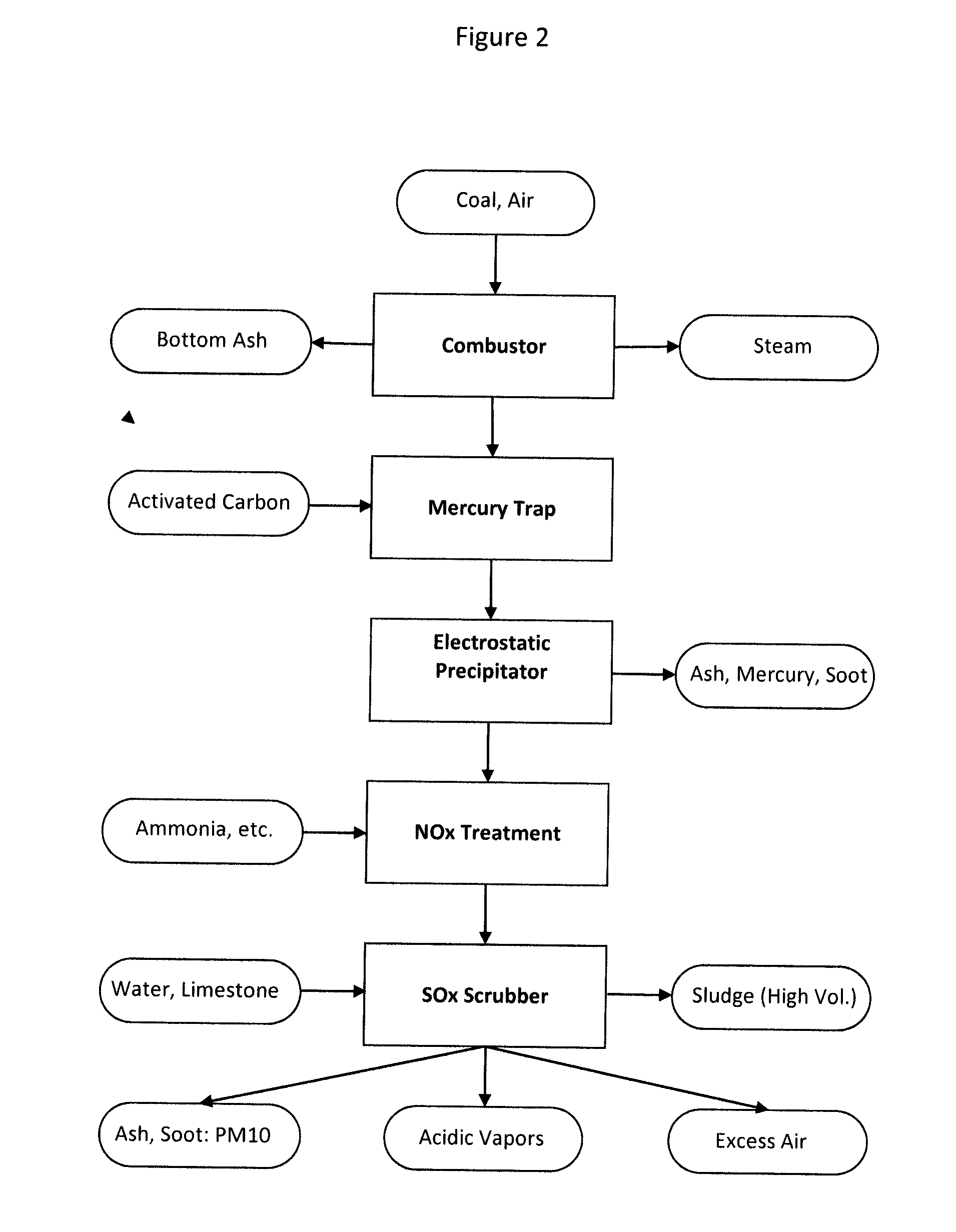

a combustor and low-quality technology, applied in the direction of pulverizing fuel burners, combustion types, burners, etc., can solve the problems of low combustion efficiency, high cost of nuclear technology, and depletion of fossil fuel supplies, so as to improve combustion, facilitate combustion stability and efficiency, and accelerate fuel heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]1. Devolatilization Module

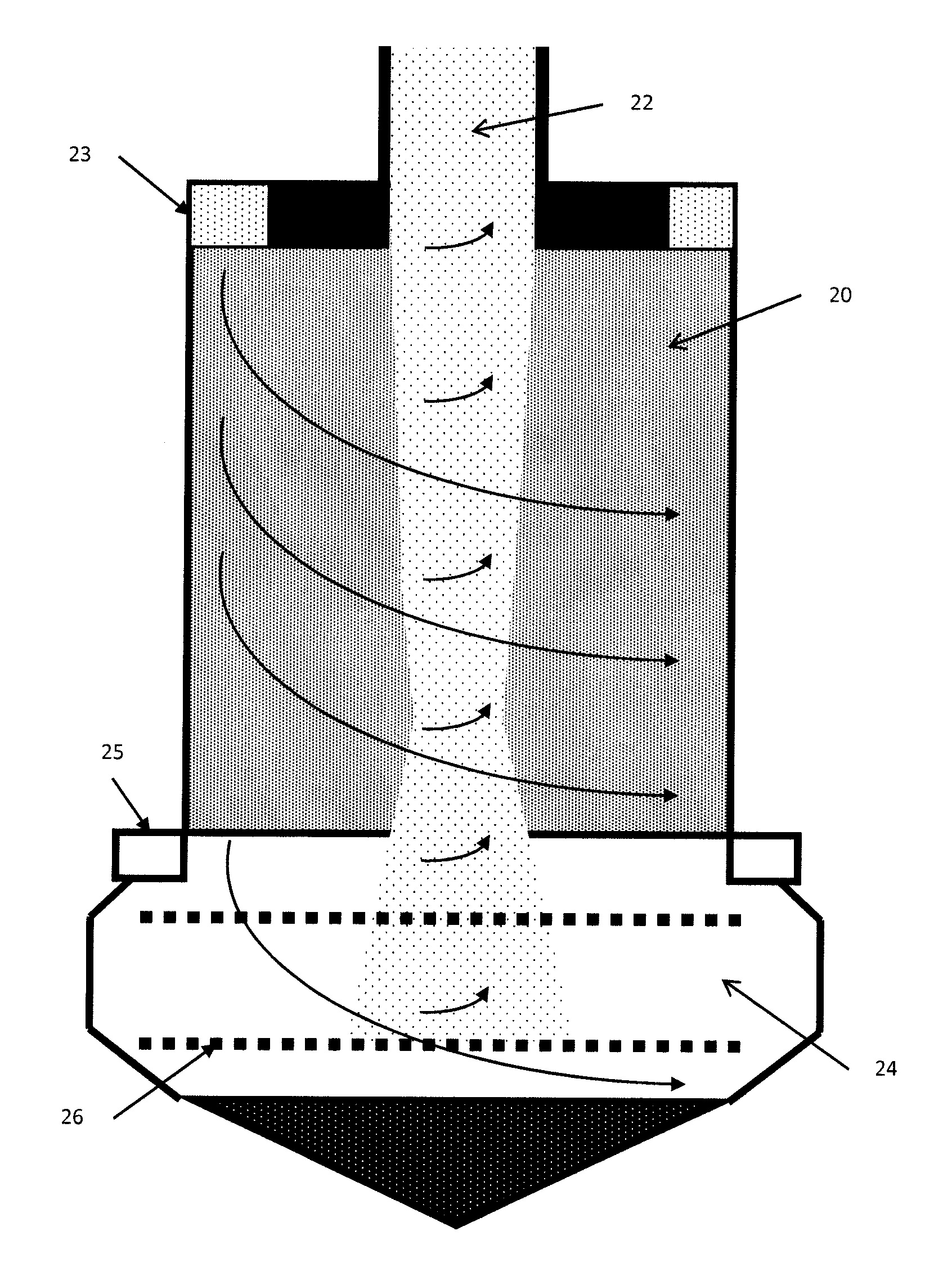

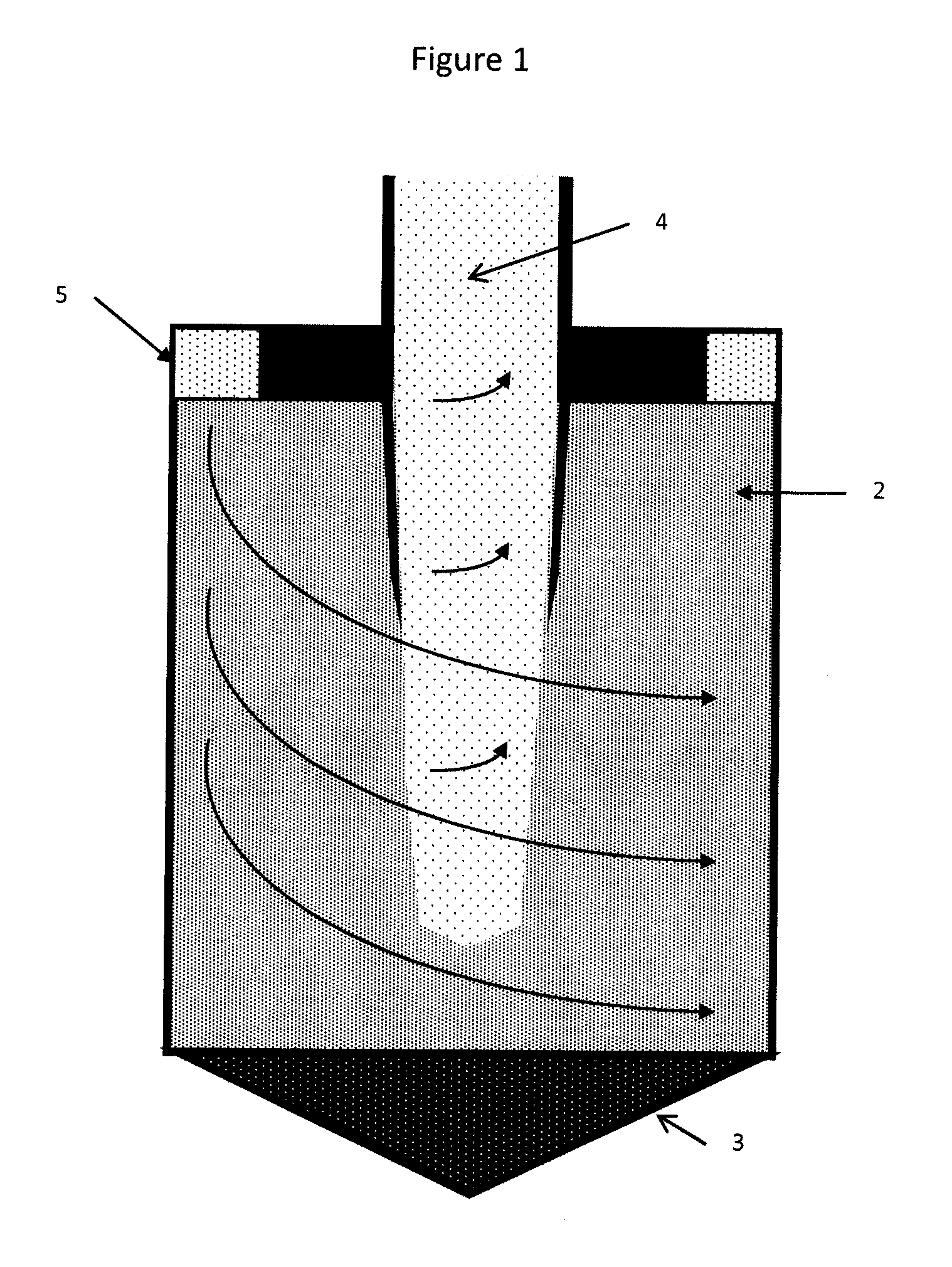

[0035]The first component is a devolatilization module 10 coupled to a second char extraction / volatile collection module. The devolatilization module produces two separate streams. A first stream is a partially burned, highly fuel rich volatile stream for later combustion, as will be explained later. This stream contains most of the gas yield. A second stream contains concentrated, partially burned char particles. This stream contains minimum gas phase products that are burned in the char combustor module, also to be explained later.

[0036]As seen in FIG. 3, the devolatilization module has an inlet 11 allowing the introduction of air and fuel followed by a quarl zone 12 and recirculation zones 13. The devolatilization module has two sections to form two separate streams; a volatile generation / combustion section 14, coupled to a subsequent char extraction / volatile collection section 15. The inner surface of the devolatilization module can be refractory ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com