Athermal radiation type oil burner and a method for reducing greenhouse gas emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

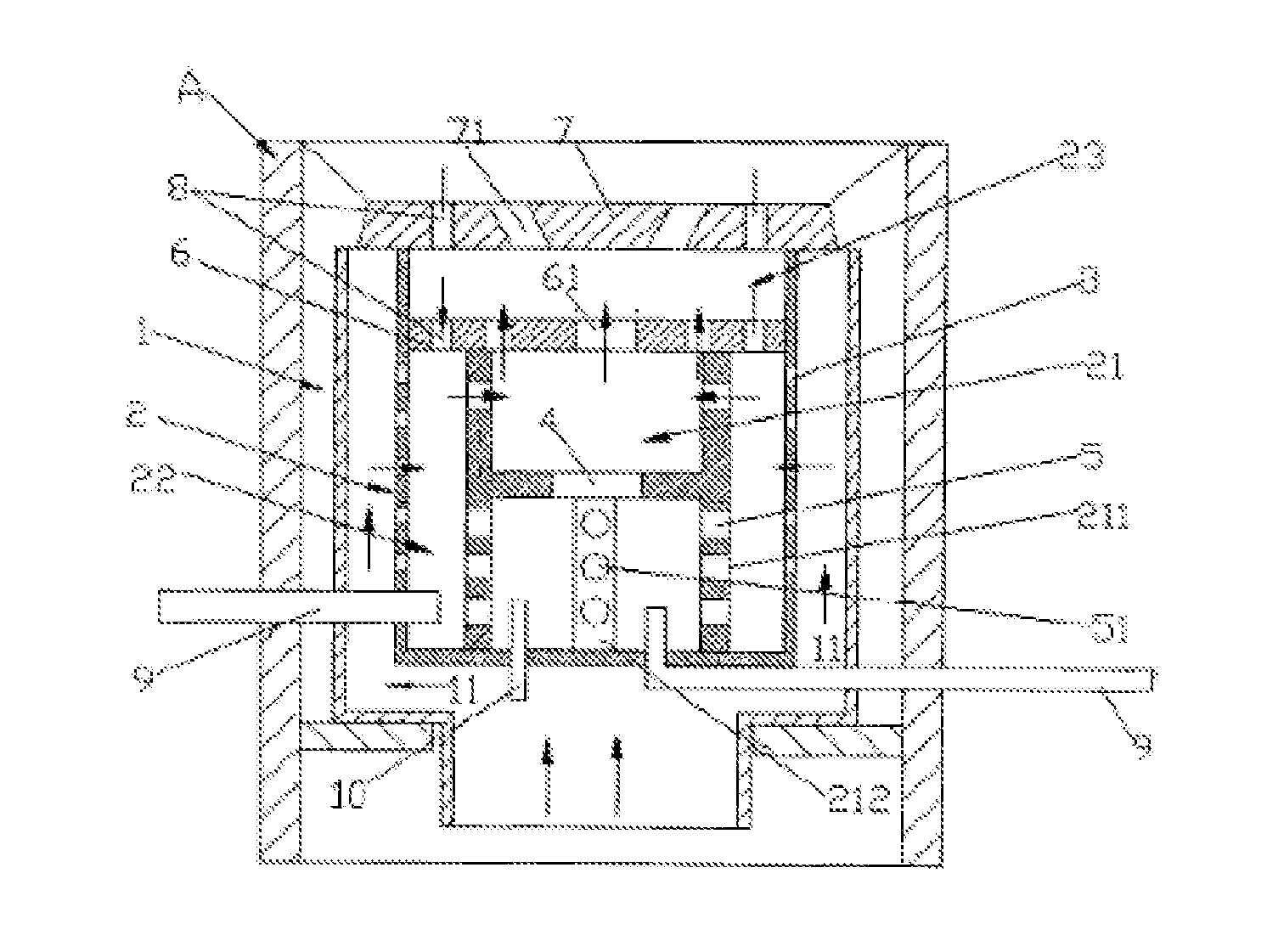

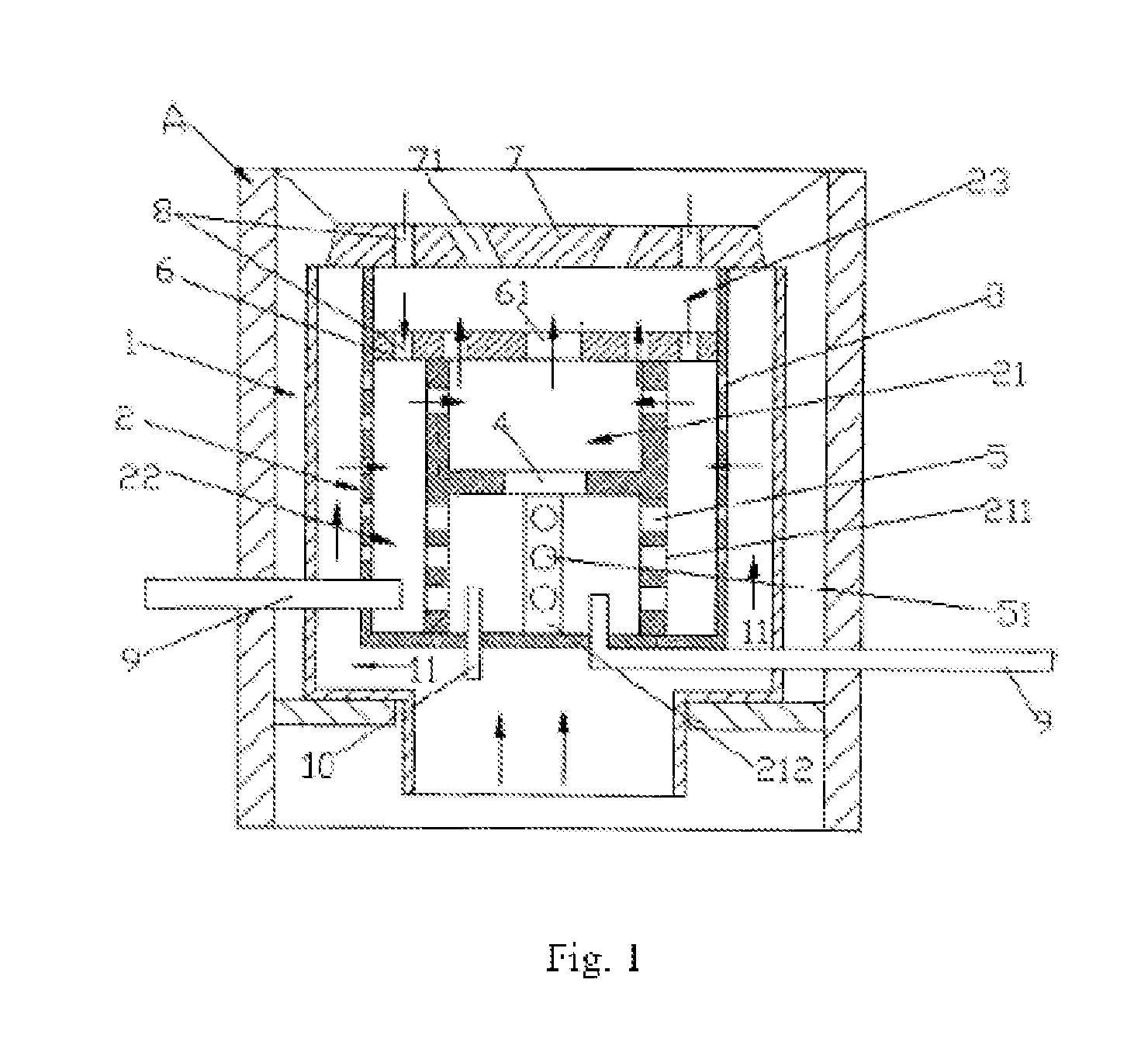

[0018]A method of the present invention for reducing greenhouse gas (CO2) emissions is to install an athermal radiation type oil burner on a stove A.

[0019]The athermal radiation type oil burner, as shown in FIG. 1, includes: a furnace body 1 in which a hearth 2 is placed; an air chute 11 is arranged between the furnace body 1 and the hearth 2; the hearth 2 composed of a casing with multiple through holes 3 includes a primary oil supply combustion chamber 21, a secondary oil supply combustion chamber 22 and an obstruction chamber 23; the hearth 2 is provided inside with two oil ports 9 that are respectively connected to a connecting tube, one connecting tube being connected to a lower end of the primary oil supply combustion chamber 21, the other connecting tube being connected to a lower end of the secondary oil supply combustion chamber 22; the primary oil supply combustion chamber 21 is a casing 211 divided into an upper layer and a lower layer, between which is arranged an interc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com