Convective-Air butane powered portable vaporizer

a portable vaporizer, convective technology, applied in the direction of inhalators, tobacco smoke filters, etc., can solve the problems of destroying many active compounds, avoiding treatment with plant materials, and generating too much heat in combustion reaction (during smoking) to achieve the effect of restricting the flow of air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

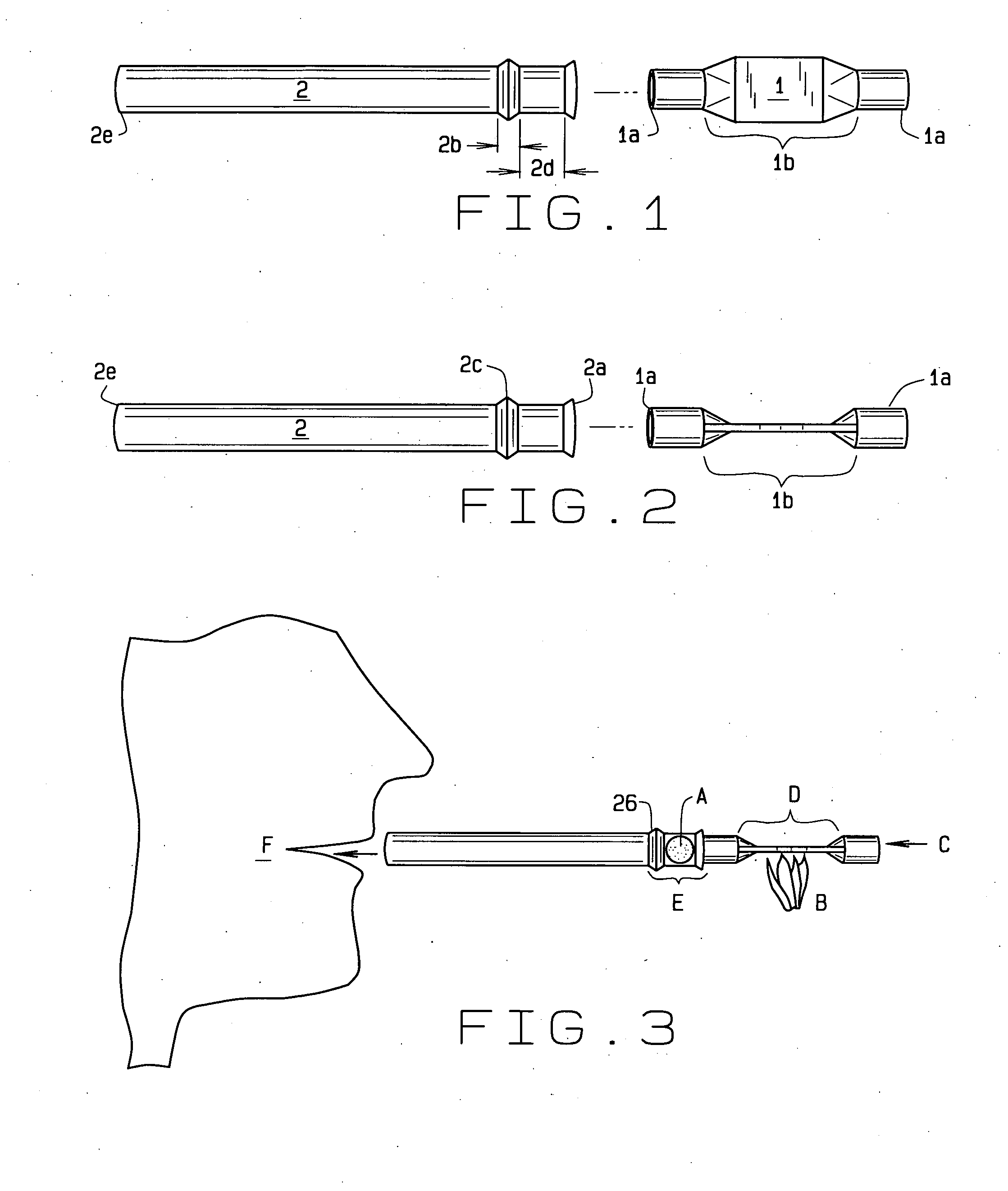

[0037]The vaporization system consists of two components—a heat exchanger and a mouthpiece. The heat exchanger is formed from a stamped piece of small diameter stainless steel tubing. The mouthpiece is formed of small diameter borosilicate glass tubing—where the inner diameter of the glass tube is equal to or slightly greater than the outer diameter of the stainless steel tubing.

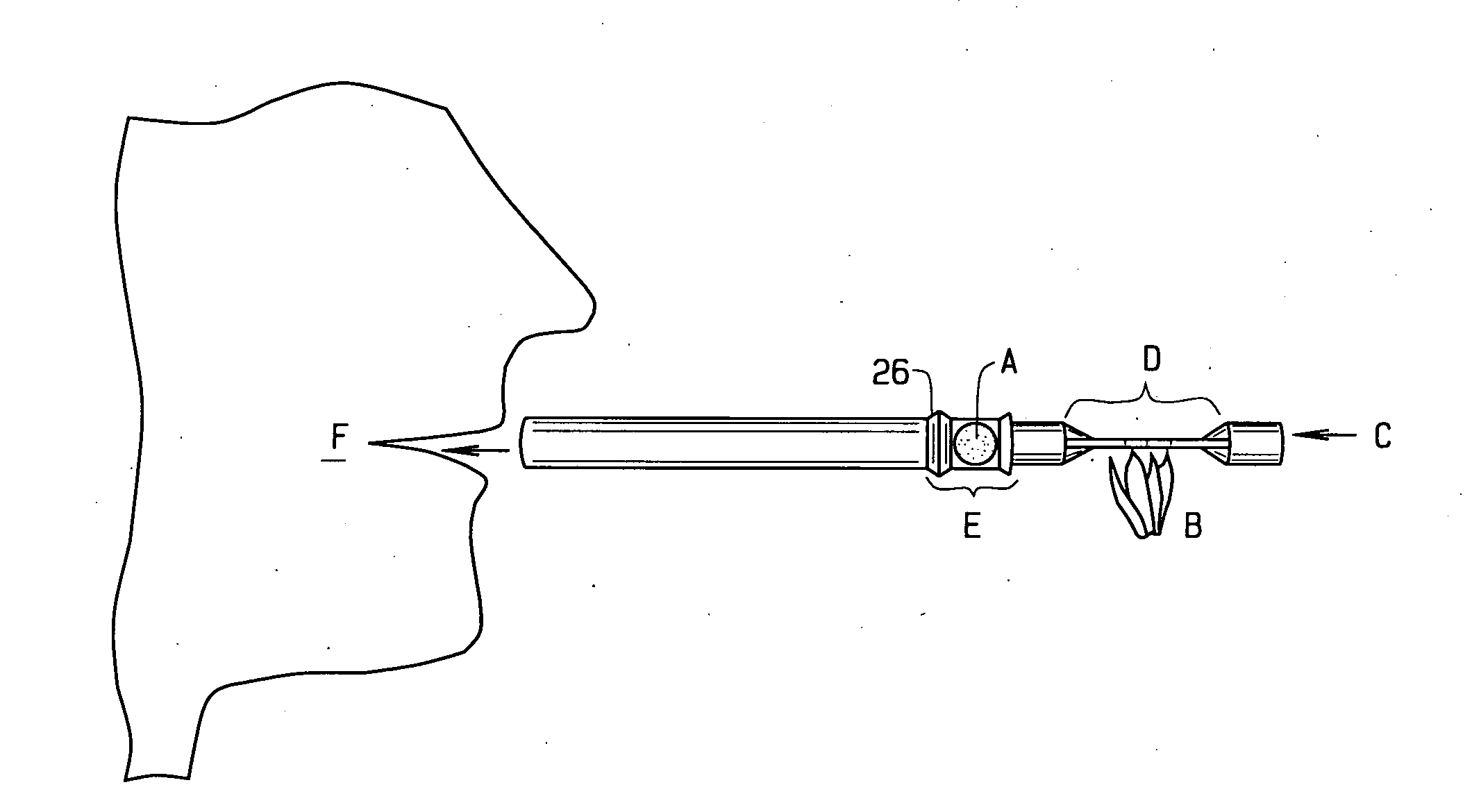

[0038]In referring to FIGS. 1 and 2, the heat exchanger 1 is a symmetrical design and as such, can be used from either end. The two ends of the heat exchanger 1a are round with a straight flat edge. Approximately ⅓ of the stainless steel tubing is flattened in the center of the length. This flattened section 1b creates a constriction in the path of the airflow. The tubing is flattened so that the walls of the tubing become flat and parallel to each other. The flattened constriction increases the ratio of metal to air (the surface area stays the same while the volume is greatly diminished), which focuses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com