Processes, systems, and apparatus for cyclotron production of technetium-99m

a technology of cyclotron and cyclotron, which is applied in the field of processes, systems and apparatus, for the production of cyclotron, can solve the problems of serious on-going world-wide shortage of mo-99 for medical facilities and discrepancies in conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

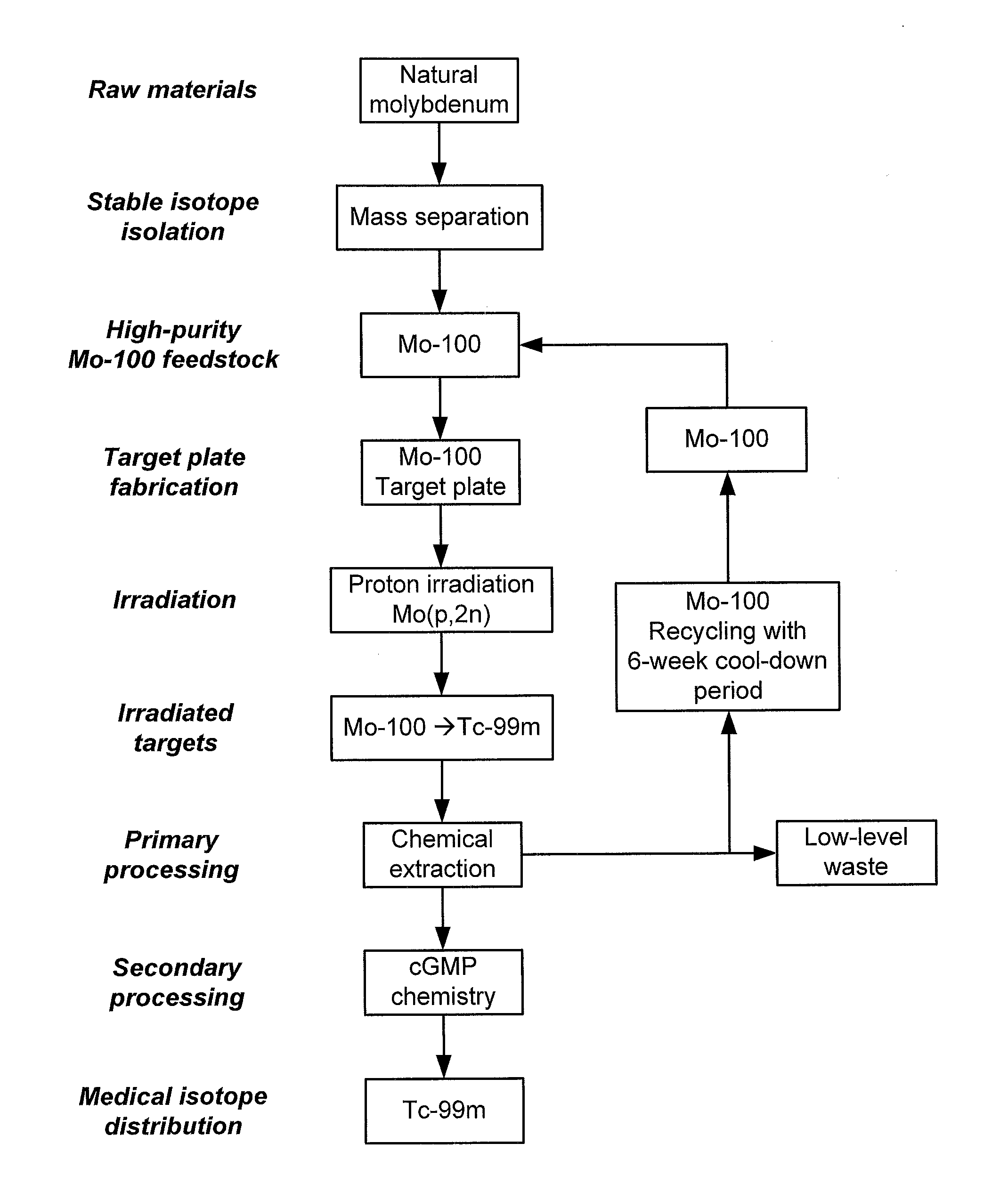

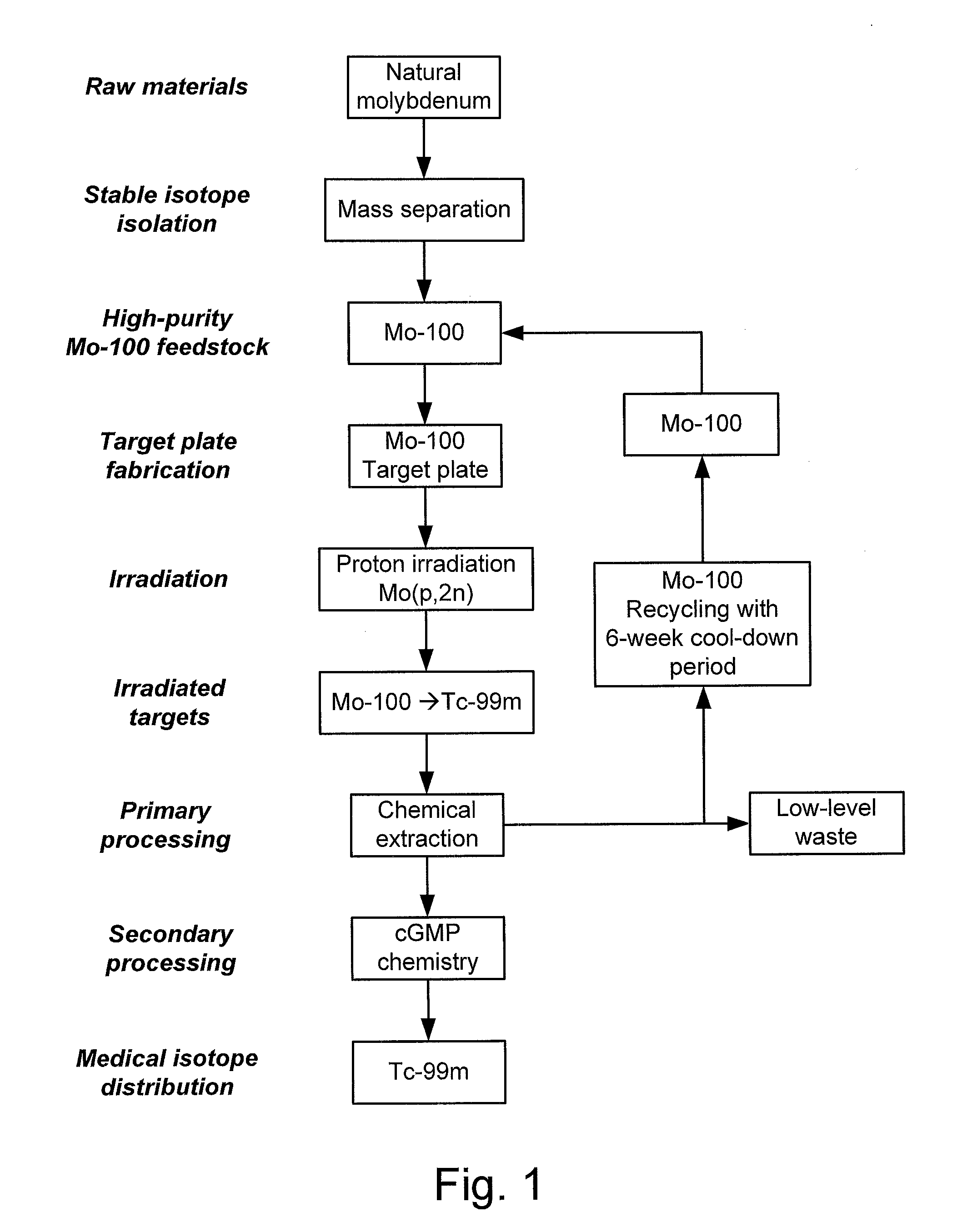

[0037]An exemplary embodiment of the present disclosure pertains to processes for producing Tc-99m by low-energy proton radiation of Mo-100 using proton beams produced by accelerators such as cyclotrons. Suitable proton energy for the processes of the present disclosure is from a range of about 10 MeV to about 30 MeV incident on the target. A flowchart outlining an exemplary process is shown in FIG. 1. The process generally follows the steps of:

[0038]1) Processing a supply of enriched Mo-100 metal powder to produce a Mo-100 powder with a consistent grain size of less than about 10 microns.

[0039]2) Depositing a coating of the processed Mo-100 powder onto a target plate comprising a transition metal, by electrochemical and / or electrophoretic deposition.

[0040]3) Sintering the coated target plate in an inert atmosphere for about 2 hours to about 10 hours at a temperature of about 1200° C. to about 2000° C.

[0041]4) Securely engaging the sintered target plate into a target holder. A targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com