Electrode composition for removing nitrogen oxides, and apparatus and method thereof

A nitrogen oxide, electrode technology, used in chemical instruments and methods, electrodes, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

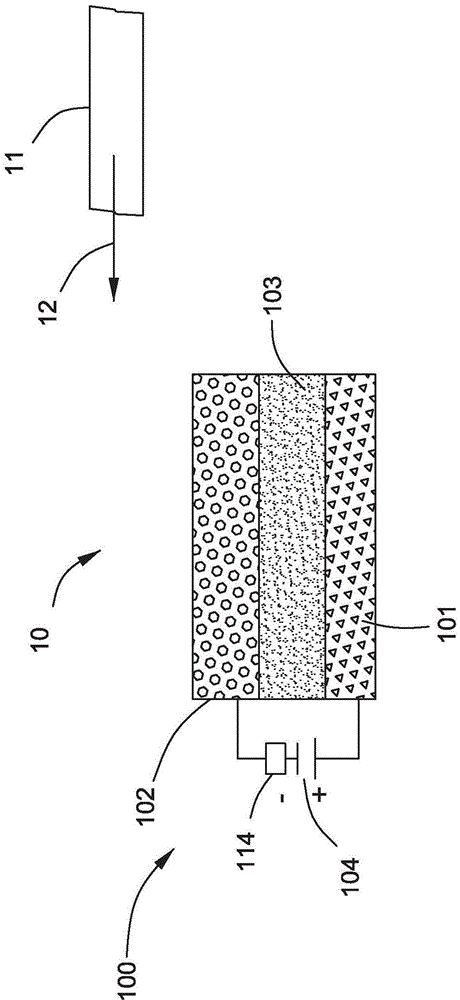

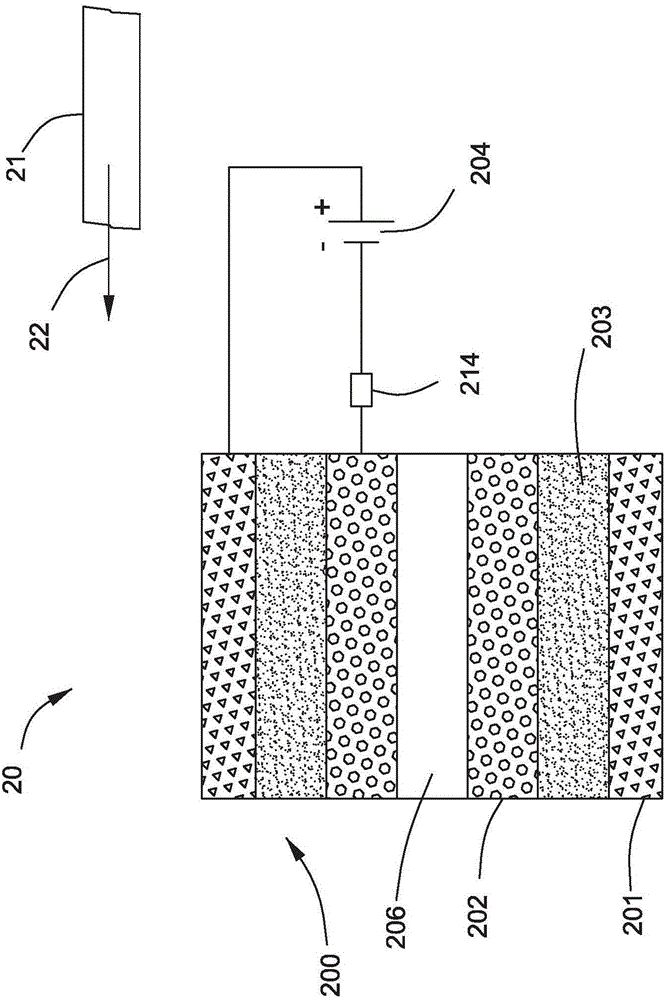

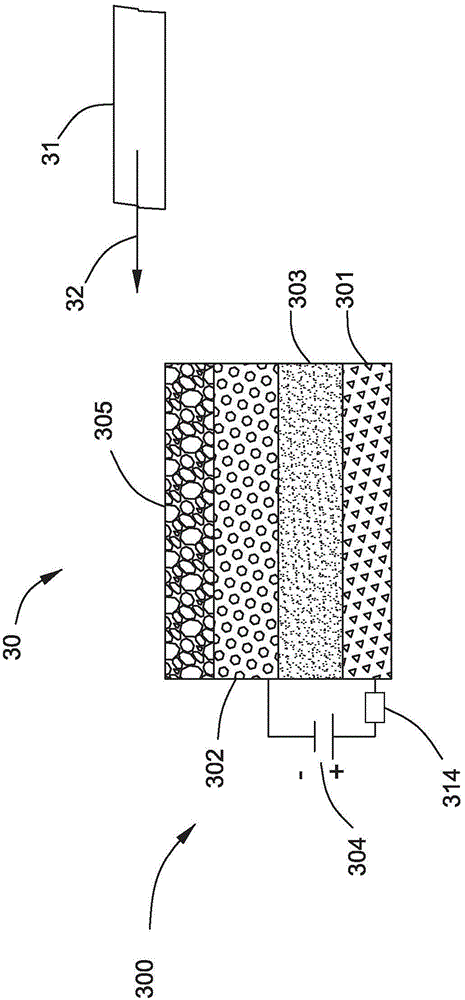

Image

Examples

example 1

[0049] Example 1La 0.6 Sr 0.4 Ni 0.3 mn 0.7 o 3 synthesis

[0050] La 2 o 3 ,SrCO 3 ,Mn(AC) 2 4H 2 La 0.6 Sr 0.4 Ni 0.3 mn 0.7 o 3 . X-ray diffraction (XRD) analysis showed that the synthesized La 0.6 Sr 0.4 Ni 0.3 mn 0.7 o 3 The material has a pure phase.

example 2

[0051] Example 2BaZr 0.1 Ce 0.7 Y 0.2 o 3 powder preparation

[0052] BYZGR 0.1 Ce 0.7 Y 0.2 o 3 Powders are prepared by solid state reaction methods. Stoichiometric high-purity barium carbonate, zirconia, yttrium oxide and ceria powders (all from Sinopharm Chemicals Co., Ltd., Shanghai, China) were mixed with ethanol and ball milled for about 16 hours. The resulting mixture is dried and calcined in air at about 1450°C for about 6 hours to form BaZr 0.1 Ce 0.7 Y 0.2 o 3 powder. The calcined powder was mixed with ethanol and ball milled for about 16 hours. After ethanol drying, the fine BaZr 0.1 Ce 0.7 Y 0.2 o 3 Powder (d 50 = 1.5 μm) was prepared.

example 3

[0053] Example 3 Adsorption test

[0054] BYZGR 0.1 Ce 0.7 Y 0.2 o 3 The powder and carbon black were separately placed in a thermogravimetric analyzer with a nitrogen flow of 200 ml / min containing 100 ppm nitric oxide and 16% oxygen. The temperature was raised to 850°C at a rate of 5°C / min. A mass spectrometer (HPR20 Hyde Analytical, Warrington, England) was connected to the thermogravimetric analyzer for the detection of nitric oxide / nitrogen dioxide in the exhaust stream of the thermogravimetric analyzer. Place BaZr separately 0.1 Ce 0.7 Y 0.2 o 3 Nitric oxide signal intensity (arbitrary units) in the output stream of the thermogravimetric analyzer for powder and carbon black as Figure 5 shown.

[0055] Figure 5 Display, place BaZr 0.1 Ce 0.7 Y 0.2 o 3 The nitric oxide signal intensity in the output stream of the thermogravimetric analyzer of the powder has an obvious peak, but there is no obvious peak in the output stream of the thermogravimetric analyzer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com