Curved Automatic-Darkening Filter

- Summary

- Abstract

- Description

- Claims

- Application Information

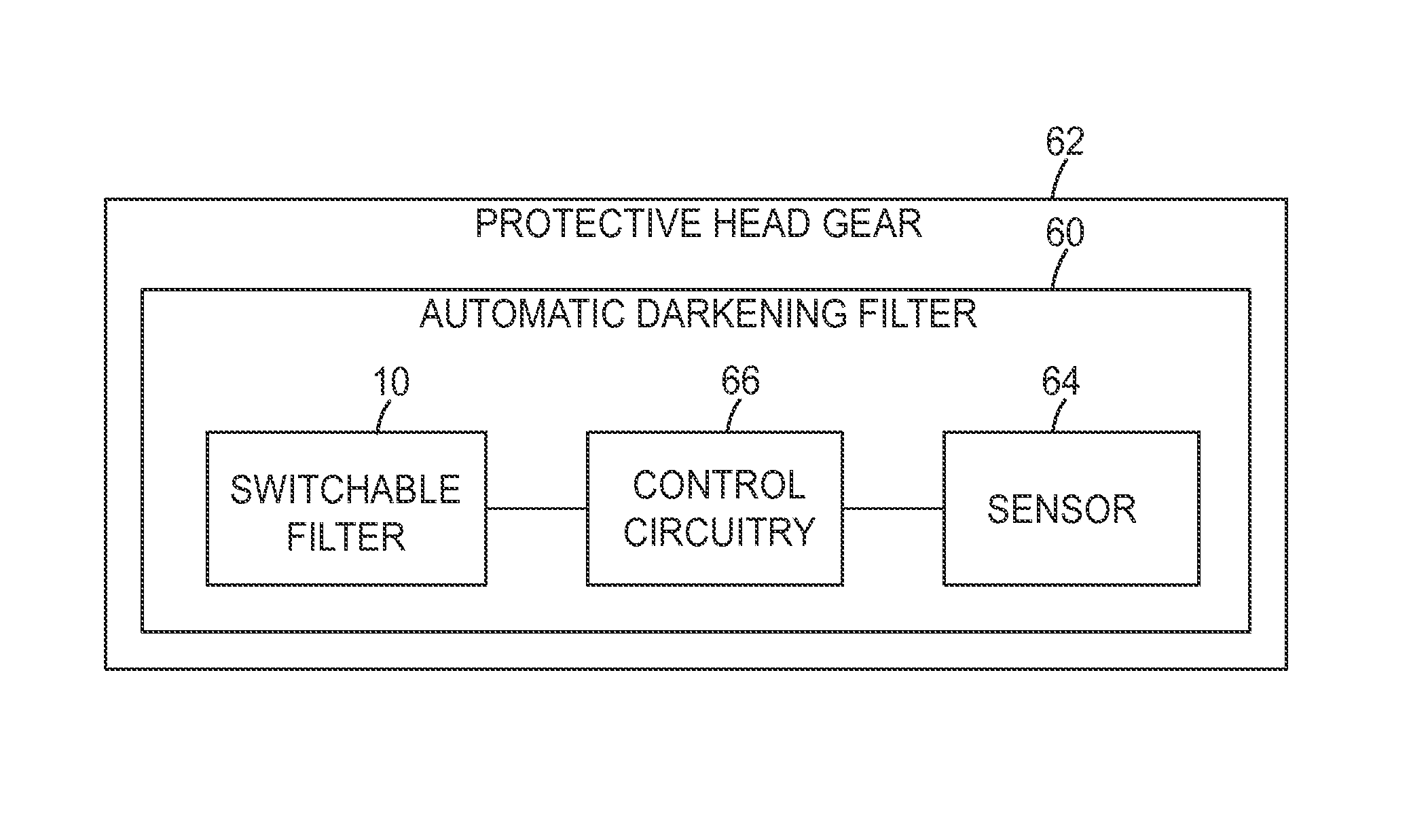

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

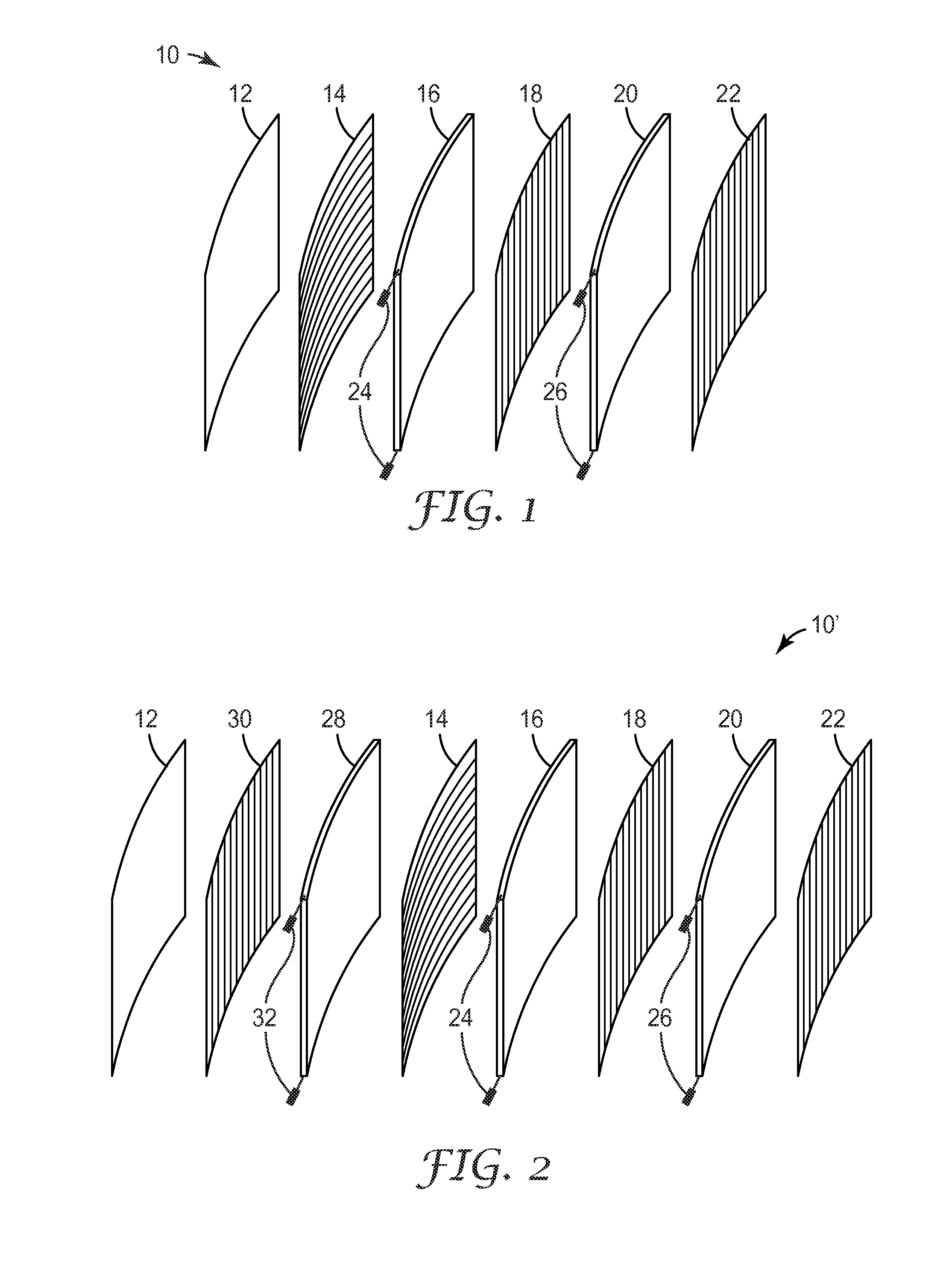

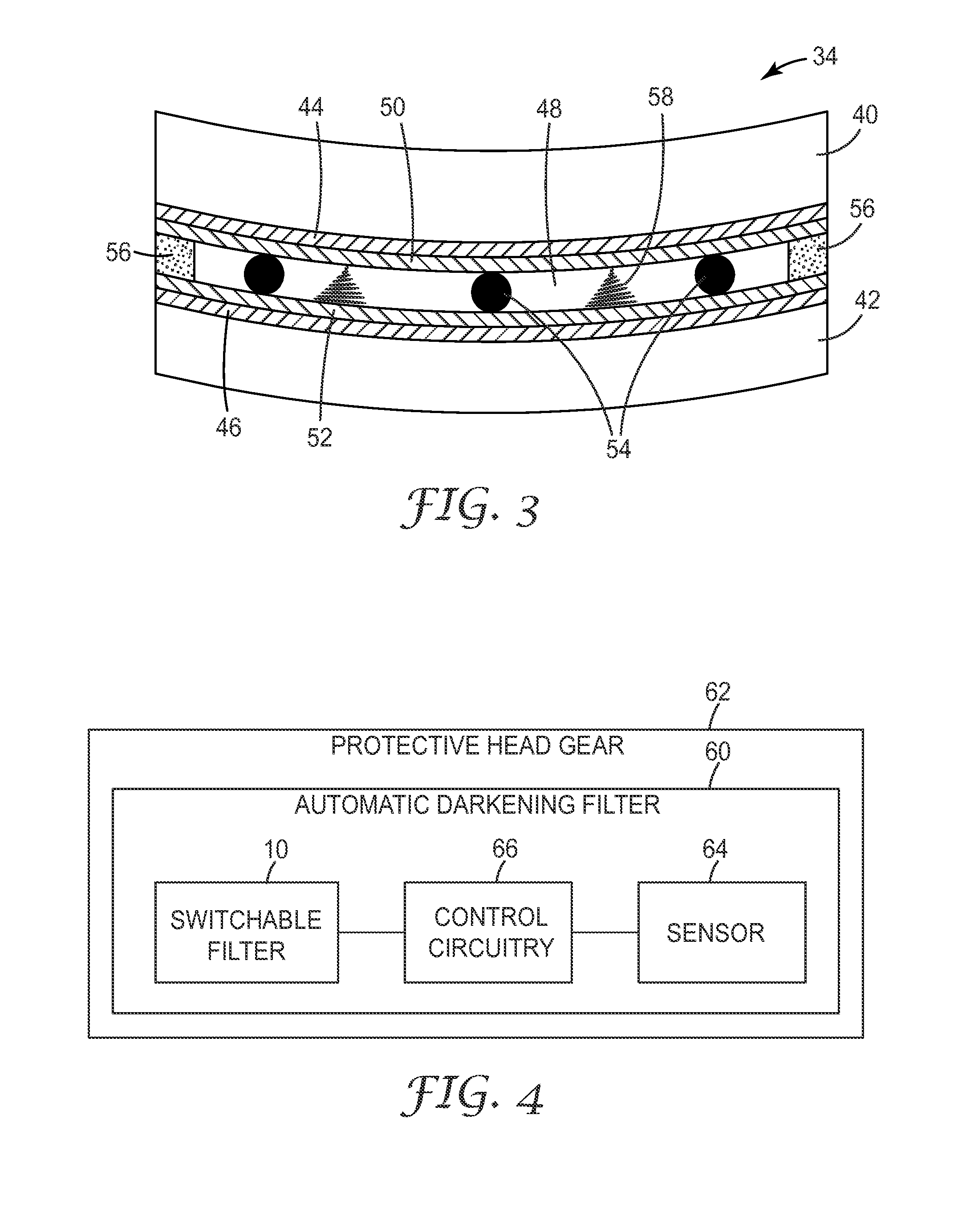

[0047]A curved liquid crystal cell for an automatic welding filter was made in the following manner.

[0048]The starting flexible glass layer was a 0.1 mm thick D263T glass from Schott Glass of Schott Glas Export, GmbH, located at Rheinallee 145, 55120 Mainz, Germany. The glass was sputter deposited with indium tin oxide (ITO). The conductivity of the coated ITO was roughly 100 ohm / square. The ITO glass was coated with a thin layer of polymide polymer. A commercially-available polyimide alignment material was coated onto the glass using a spin coating technique. The dried coating thickness was between 80 nanometers (nm) and 200 nm. The thin polymide layer was aligned by brushing it with using a rotating felt cloth. This brushed polymide, ITO / glass piece was cut into pieces for the top and bottom portion of the liquid crystal cell. A first piece (top) of glass was rotated 90° from the orientation of the second (bottom) piece of glass to provide proper alignm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com