Tire vulcanization/retreading system using autoclave with electromagnetic induction heating

a technology of electromagnetic induction heating and autoclave, which is applied in the direction of wheels, transportation and packaging, and other domestic objects, to achieve the effects of reducing heating time, preventing oxidation of metal surfaces, and great accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

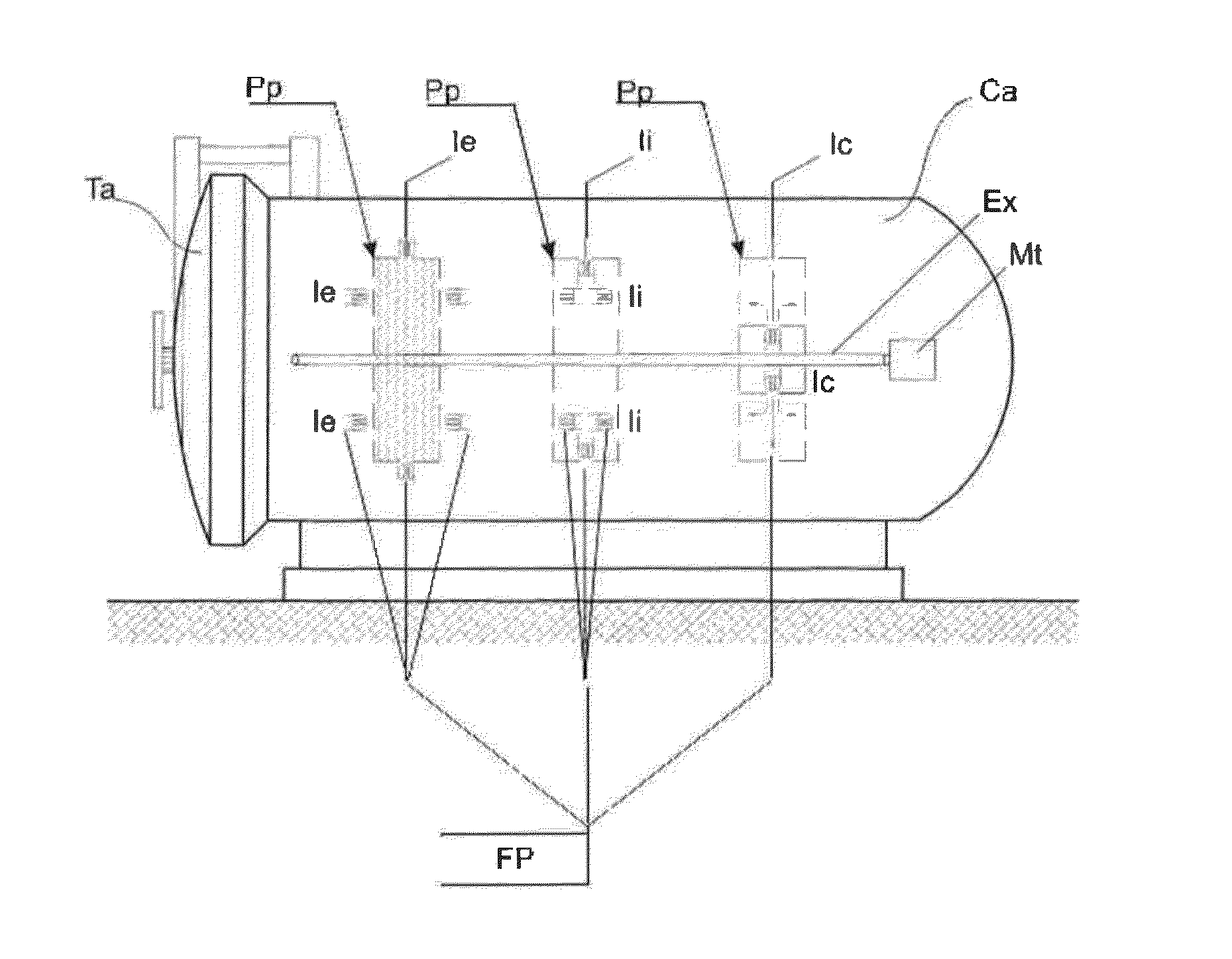

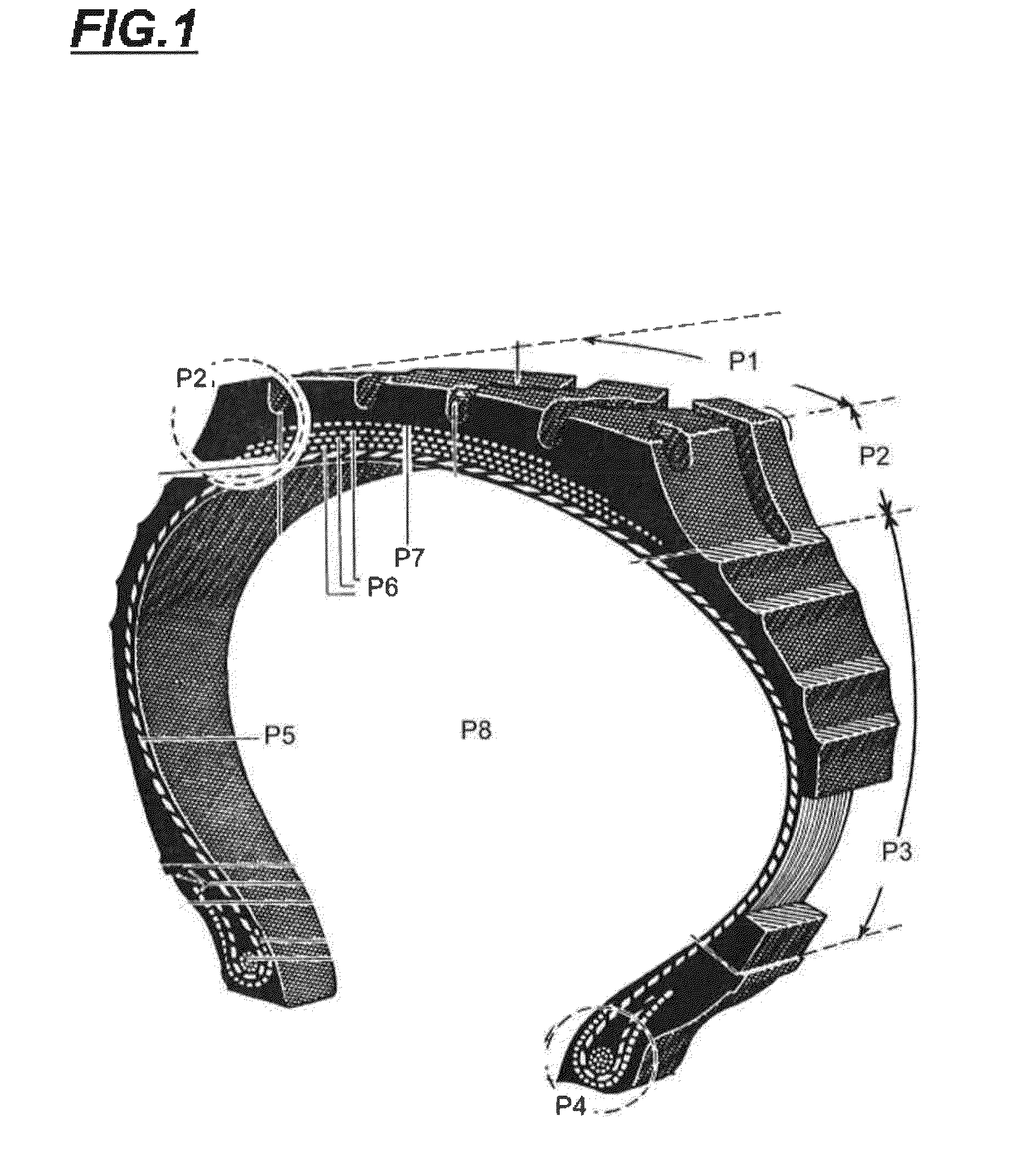

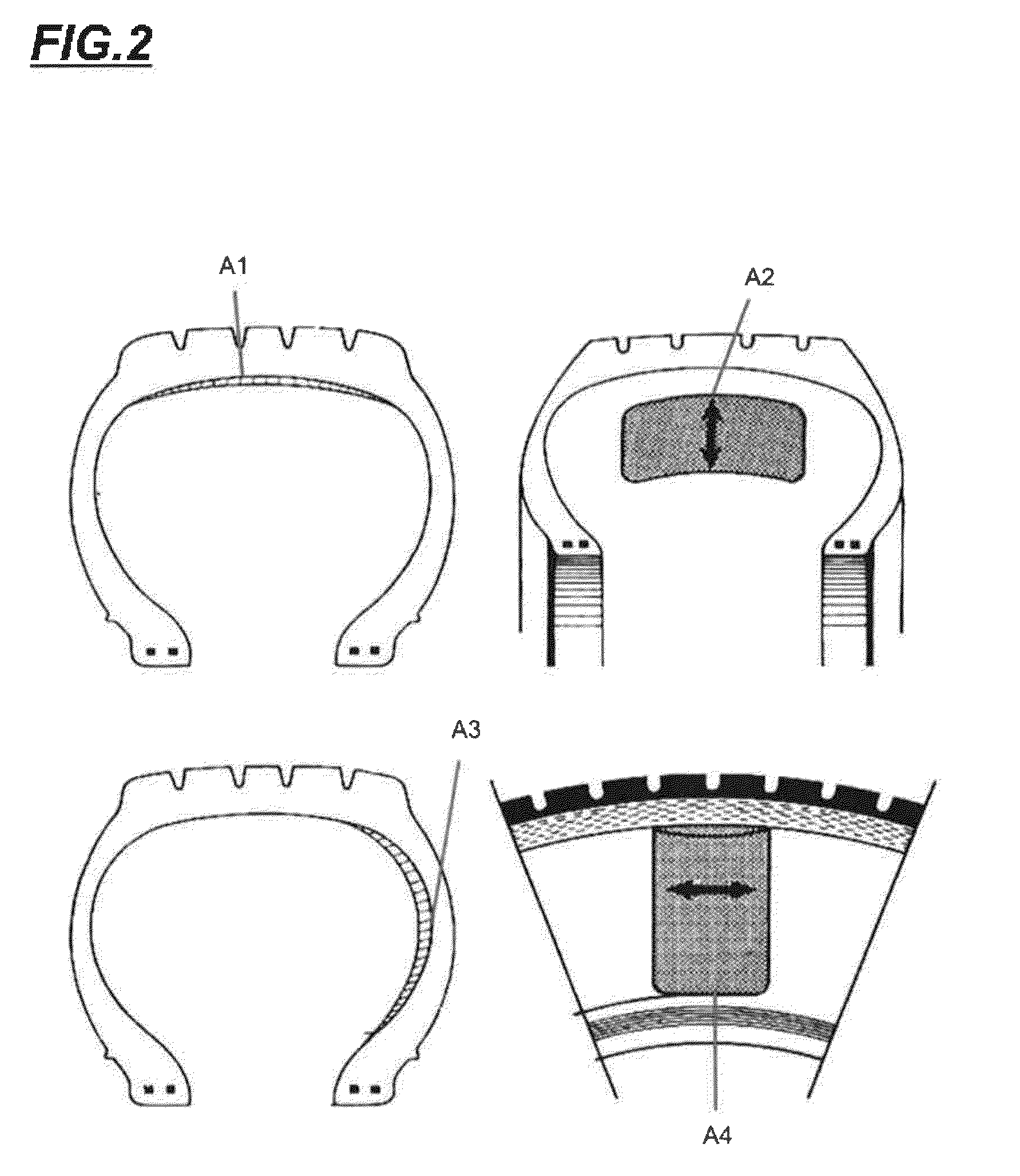

[0120]The following detailed description must be read and interpreted with reference to the drawings and block diagrams. They are diagrammatic, and represent the preferred form of performance of the tire vulcanization stage with induction heating system. It is not designed to limit the scope of the invention. The invention is limited to the explanation in the claims.

[0121]On the basic parameters of the autoclave vulcanization process with induction heating system: to get successful tire vulcanization, the basic variables involved in the process are pressure, temperature and time.

[0122]1. Pressure Parameter:[0123]1.1 For a single pressure system, the pressure is defined in the 2-6 kg / cm2 range.[0124]1.2 For a double pressure system, a process in the 4-7 kg / cm2 range is the autoclave, in the air bag, a pressure in the 6-9 Kg / cm2 range, and a differential pressure between the air bag and the autoclave in the range of 1.5-3 Kg / cm2 greater than the air bag;[0125]1.3 For a triple pressure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com