Thin Diamond Film Bonding Providing Low Vapor Pressure at High Temperature

a diamond film and high temperature technology, applied in the direction of superimposed coating process, soldering apparatus, manufacturing tools, etc., can solve the problems of high vapor pressure of suitable metals at their melting point, difficult to achieve for a fragile part, and forming metal carbides that are relatively inert and difficult to remove chemically

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

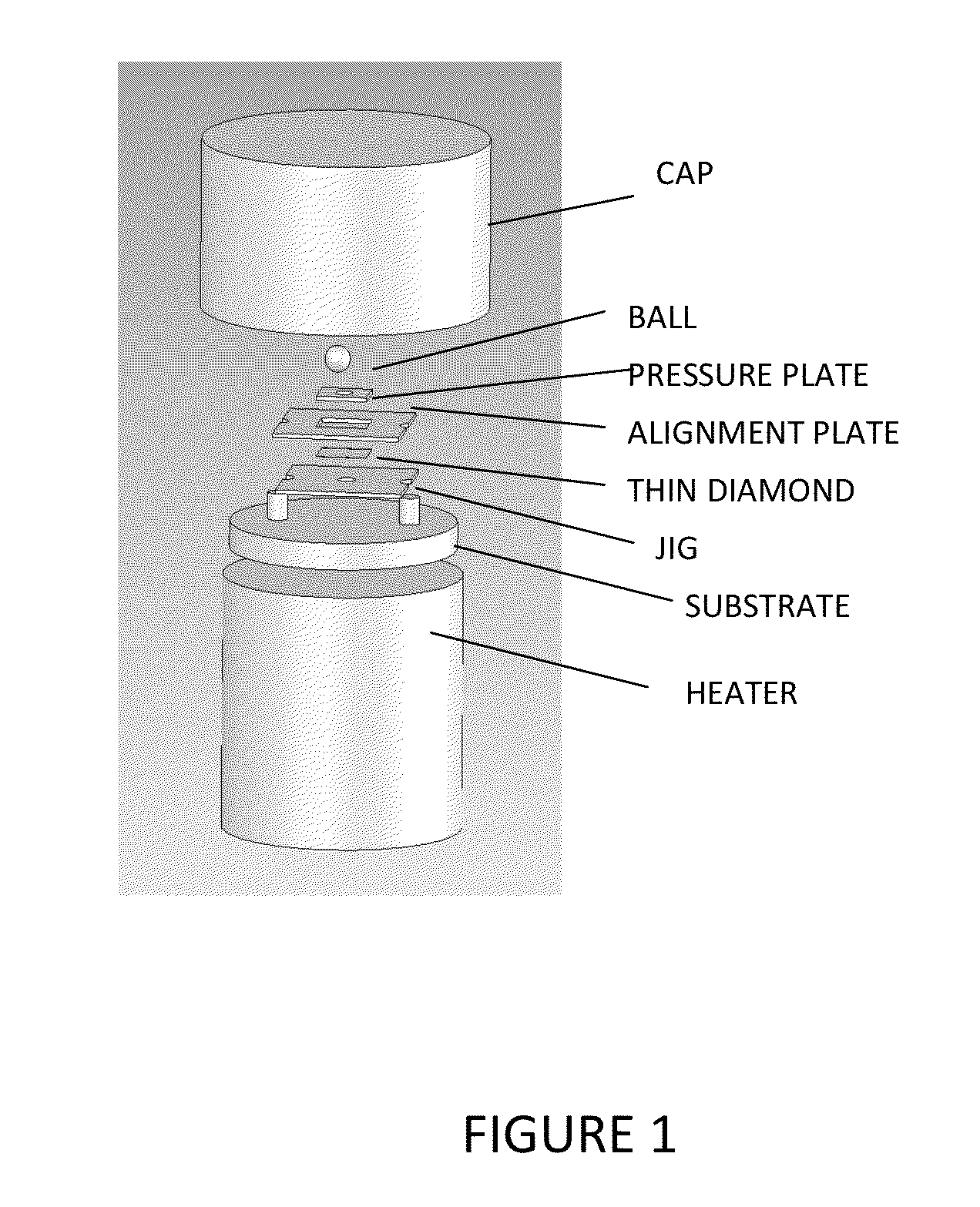

Method used

Image

Examples

example

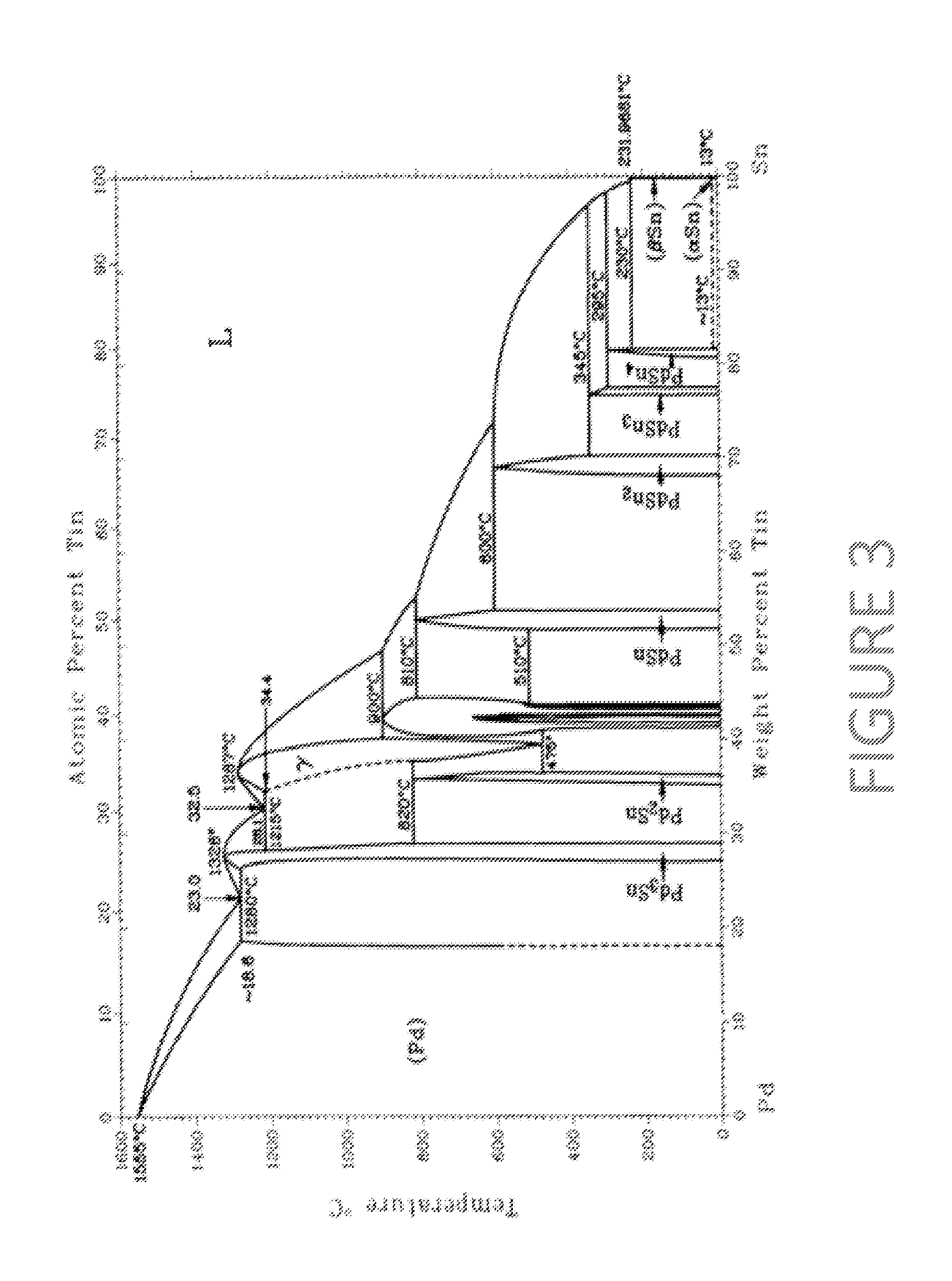

[0028]Since neither Pd nor Sn will react readily with diamond, we first coat the diamond surfaces in the areas to be bonded with an adhesion layer of Chromium (Cr). The Cr layer also forms an electric contact to the thin diamond film, needed to remove charge generated by the primary electron beam.

[0029]The Cr is thin enough to allow the primary electron beam to pass through it without excessive energy loss. The Cr layer thickness can be varied somewhat depending on the intended primary beam energy and current. A thinner layer may be used for very low primary beam energies or a thicker layer can be used to reduce resistive loss.

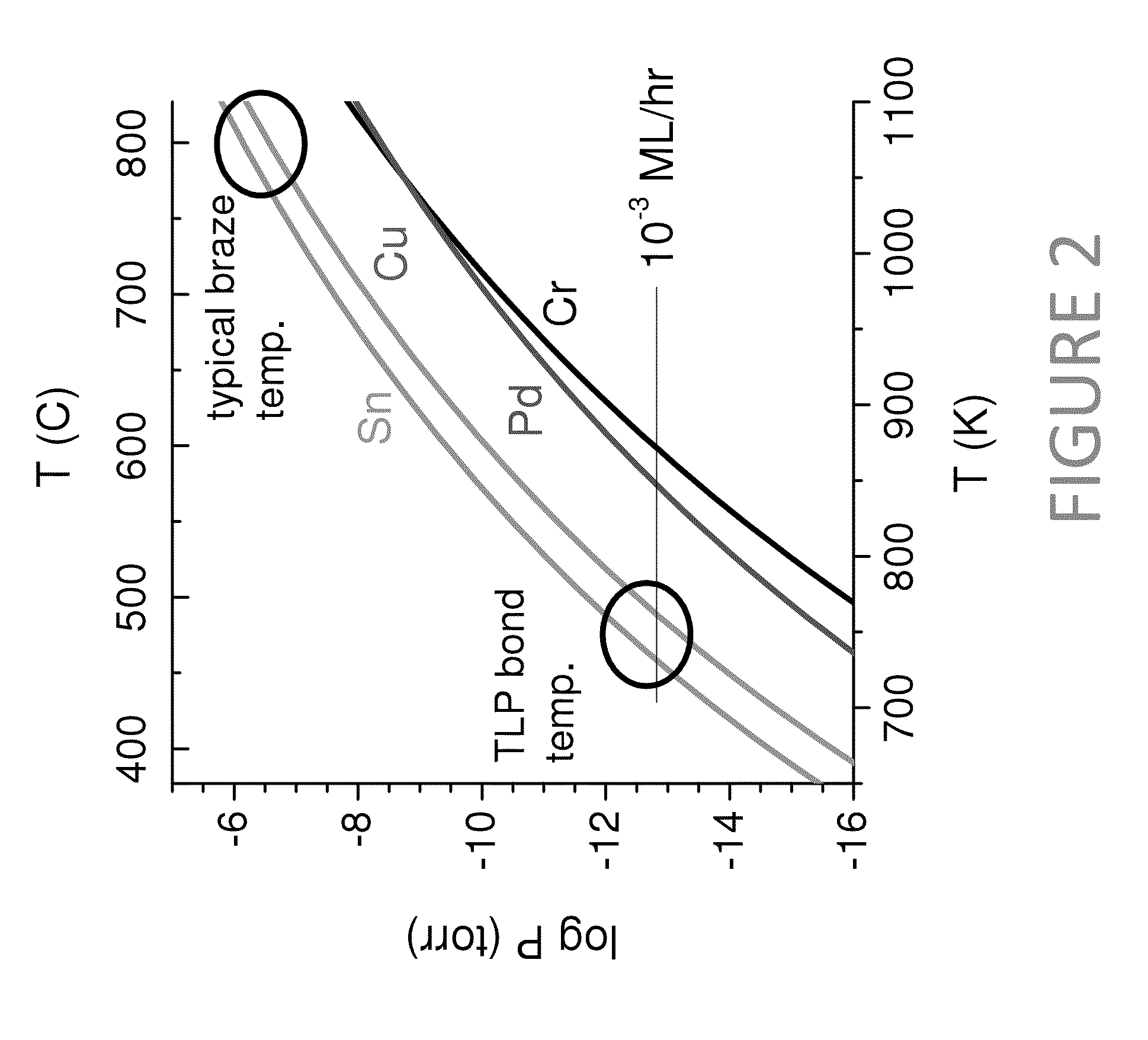

[0030]The Cr coating on the substrate is patterned using a shadow mask; the Cr coating on the thin diamond film is not patterned. Before depositing the Cr using a magnetron sputter source, we remove adsorbed gases from the diamond by heating inside the vacuum chamber to 500° C. until the pressure drops below 2×10−7 torr. This step ensures the Cr will chemicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com