Polyurethane polishing pad

a technology of polyurethane and polishing pads, which is applied in the field of polishing pads, can solve the problems of lack of planarization and copper dishing properties of the polishing pads produced from these formulations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

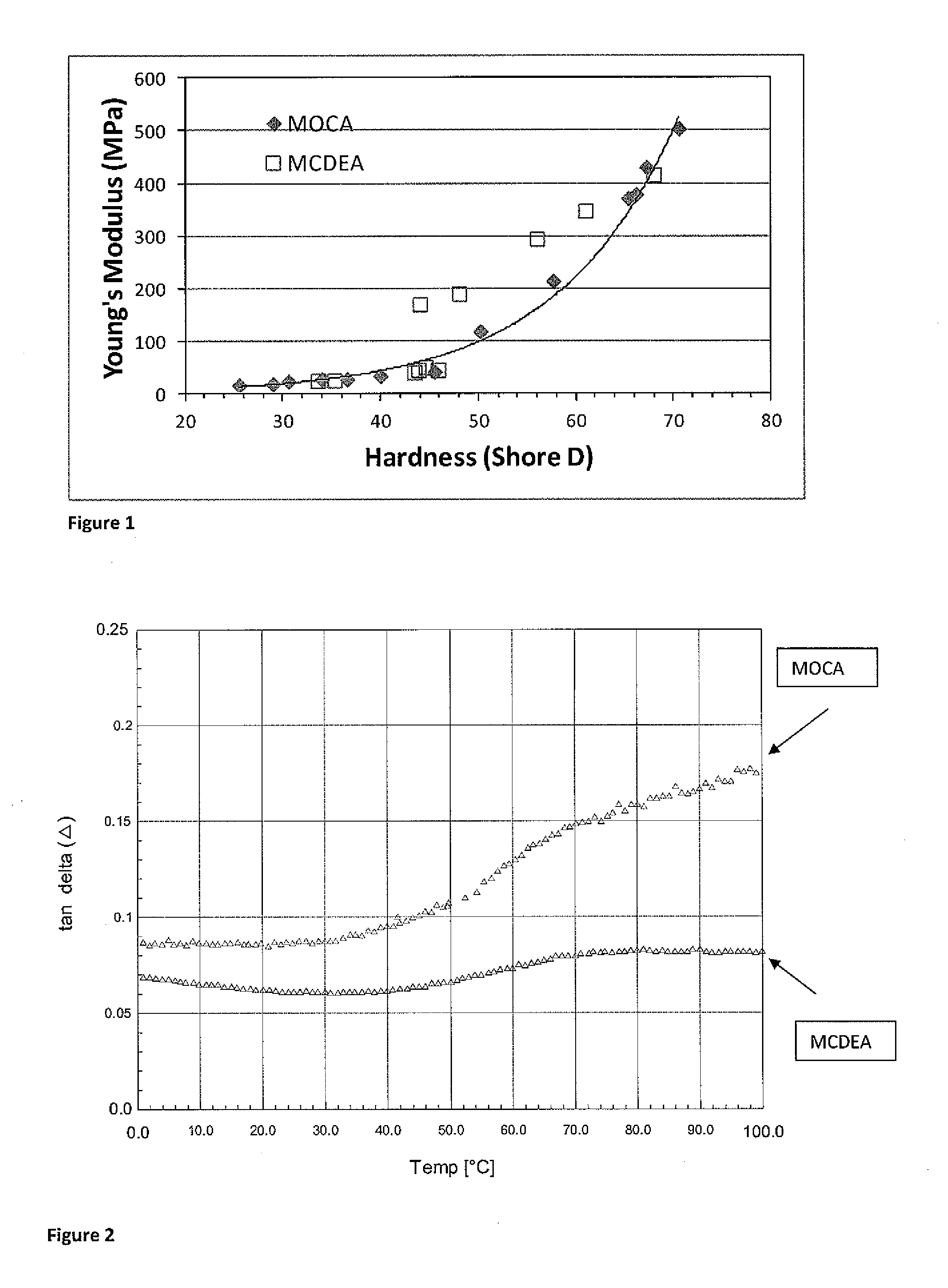

Image

Examples

example 1

[0023]Table 1 includes the formulations for a series of pads manufactured to the above method with various prepolymers, isocyanate amounts and curatives.

TABLE 1Adiprene ® and Vibrathane ® are urethane prepolymer products of Chemtura Corporation all NCO values represent nominal amounts.UnreactedIsocyanateNCOStoichiometryFormulationPolyol BackbonePrepolymerWt. %Curative(%)A-1PTMEGAdiprene LF750D8.9MOCA85B-1PTMEGAdiprene LF750D8.9MOCA105C-1PTMEGAdiprene LF750D8.9MOCA115D-1PTMEG / PPGAdiprene LF750D / 8.8MOCA95LFG740DE-1PTMEG / PPGAdiprene LF750D / 7.3MOCA97LFG963AF-1PPGVibrathane B6284.2MOCA95F-2PPGVibrathane B6284.2MOCA105G-1PTMEGAdiprene LF900A3.8MOCA95G-2PTMEGAdiprene LF900A3.8MOCA105H-1PTMEGAdiprene LF800A2.9MOCA95H-2PTMEGAdiprene LF800A2.9MOCA105I-1PPGAdiprene LFG963A5.75MOCA90I-2PPGAdiprene LFG963A5.75MOCA102.51PPGAdiprene LFG963A5.75MCDEA102.52PPGAdiprene LFG963A5.75MCDEA110E-2PTMEG / PPGAdiprene LF750D / 7.3MCDEA110LFG963AE-3PTMEG / PPGAdiprene LF750D / 7.3MCDEA110LFG963AJ-1PPGAdiprene LFG963A...

example 2

[0027]Porous formulations of pad samples used in bulk copper polishing tests were modified as illustrated in Table 3.

TABLE 3EXPANCELEstimatedUnreactedPolymerMicrosphereNCOMicrospheresMicrosphereDensityFormulationWt. %CurativeStoichiometry %(Diameter)Wt. %(g / cc)1-A5.75MCDEA102.5461DE20d701.920.070(20 μm)I-15.75MOCA90551DE40d421.120.042(40 μm)E-47.3MOCA97551DE20d602.060.060(20 μm)L-18.8MOCA95551DE20d601.350.060(20 μm)

[0028]A polishing defect comparison was then completed between formulation 1A and comparative formulation E-4. The pads Polishing conditions were with grooves having a depth of 30 mils (0.760 mm), width of 18 mils (0.457 mm) and a pitch of 70 mils (1.778 mm) on an Applied Materials Reflection LK tool, with a wafer velocity of 87 rpm and a platen velocity of 93 rpm using in-situ conditioning with a Kinik AD3BG-150855 diamond conditioner using Planar Solution CSL9044C slurry. Copper blanket wafers were inspected using KLA-Tencor Surfscan SPITBI with a threshold at 0.07 micr...

example 3

[0030]The pads of Table 3 were then tested for dishing on an Applied Material Reflexion LK tool. Tables 5 and 6 below provides dishing at various densities after 60 seconds over polishing.

TABLE 5StoicPorosity10 × 10 μm50 × 50 μm100 × 100 μmFormulationPrepolyrnerCurative(%)(vol. %)(No.)(No.)(No.)E-4LF750D / LFG963AMOCA97325347568501-ALFG963AMCDEA102.524447484538L-1LFG740DMOCA95325859051050

TABLE 6StoicPorosity7 × 3 μm9 × 1 μm100 × 1 μmFormulationPrepolymerCurative(%)(vol. %)(No.)(No.)(No.)E-4LF750D / LFG963AMOCA973254778014061-ALFG963AMCDEA102.524481605676L-1LFG740DMOCA95325408301650

[0031]Tables 5 and 6 show the MCDEA pad of the invention having the best dishing performance at the densities tested. Since pads with low defects often have higher dishing, this represents an unexpected feature of the invention. Additional tests have shown that a stoichiometry of 100 to 112 percent provides the best dishing performance and exhibits the best topography performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com