Method and system for heating a bed of rocks containing sulfur-rich type iis kerogen

a technology of sulfur-rich type and bed of rocks, which is applied in the direction of fluid removal, insulation, borehole/well accessories, etc., can solve the problems of increasing economic and environmental costs of refining heavy oil, reducing the supply of conventional sweet, and increasing the difficulty of finding and accessing new resources for this premium oil. achieve the effect of reducing capital costs, improving efficiency, and high economic value of ngl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

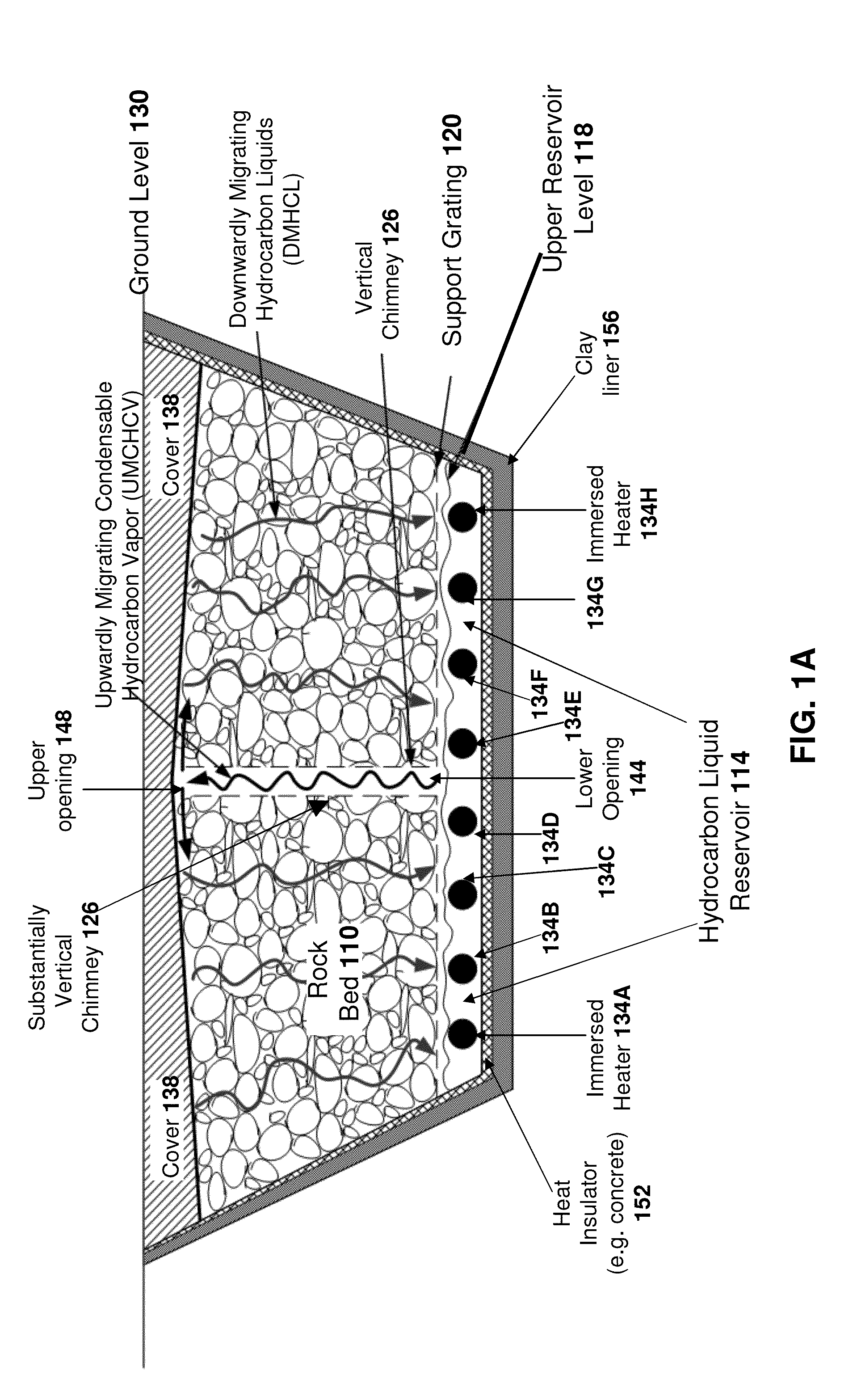

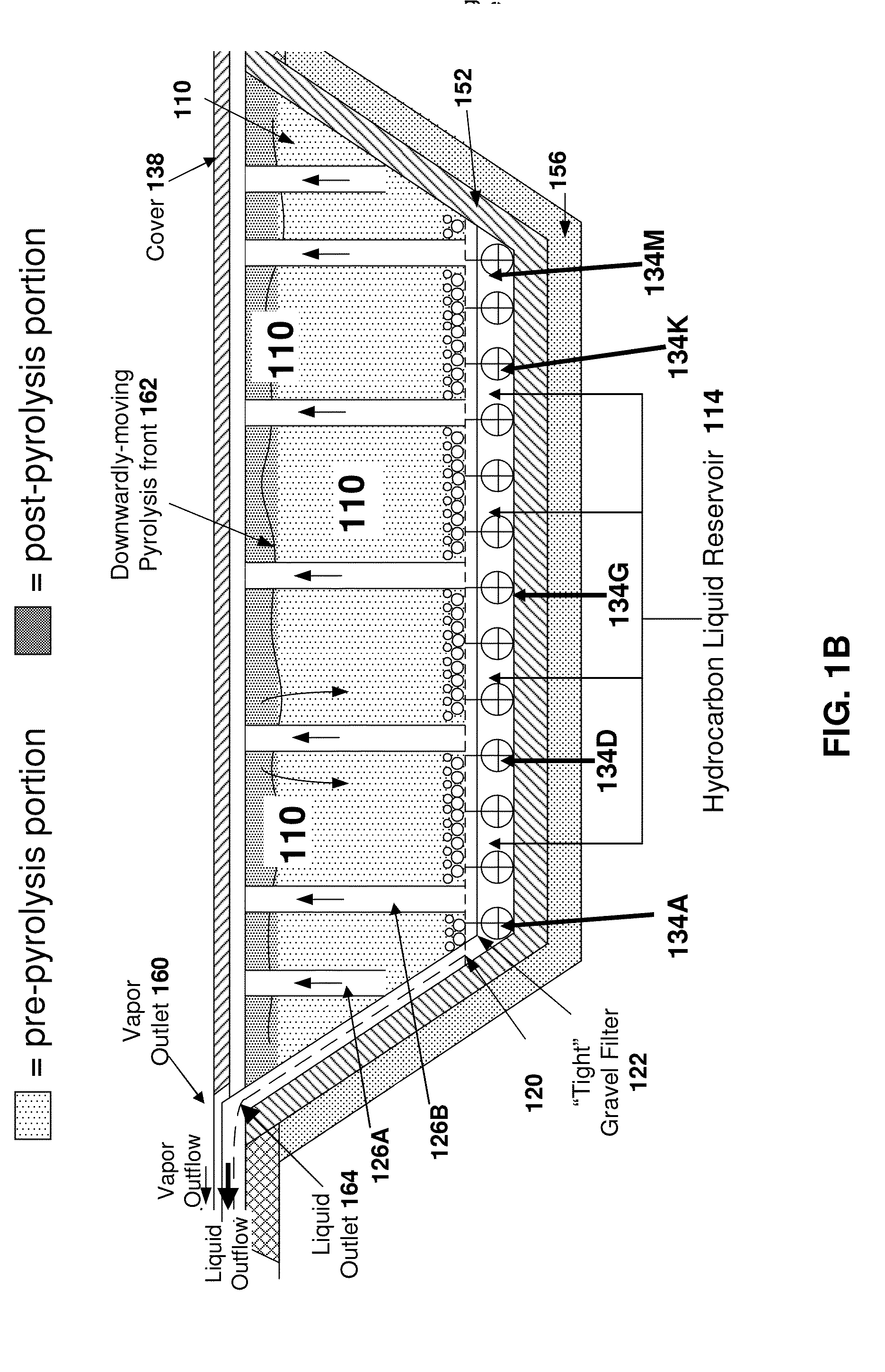

[0008]Embodiments of the present invention relate to apparatus and methods for pyrolyzing sulfur-rich type IIs kerogen within an enclosure such as a pit or an impoundment or a container. Hydrocarbon-containing rocks (i.e. pieces of oil shale including sulfur-rich type IIs kerogen) are introduced into the enclosure to form a bed (e.g. a packed-bed) of rock therein. Oxygen may be evacuated (e.g. under vacuum or by means of an inert sweep gas) to create a substantially oxygen-free environment within the enclosure. In different embodiments, the enclosure may be a pit, or an impoundment or a container. The enclosure may be entirely below ground level, partially below and partially above, or entirely above ground level.

[0009]Operation of heaters in thermal communication with the hydrocarbon-containing rocks may sufficiently heat the rocks to convert the sulfur-rich type IIs kerogen thereof into pyrolysis formation fluids comprising sulfur-rich hydrocarbon pyrolysis fluids. The formation f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com