Chemical mechanical polishing conditioner with high performance

a polishing conditioner and mechanical technology, applied in the direction of grinding devices, metal-working devices, abrasive surface conditioning devices, etc., can solve the problems of reduced polishing performance and efficiency, and the structure of the cutting edge angle of the abrasive particles cannot avoid the fixing of the cutting edge angle, so as to achieve the optimal cutting ability and high performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

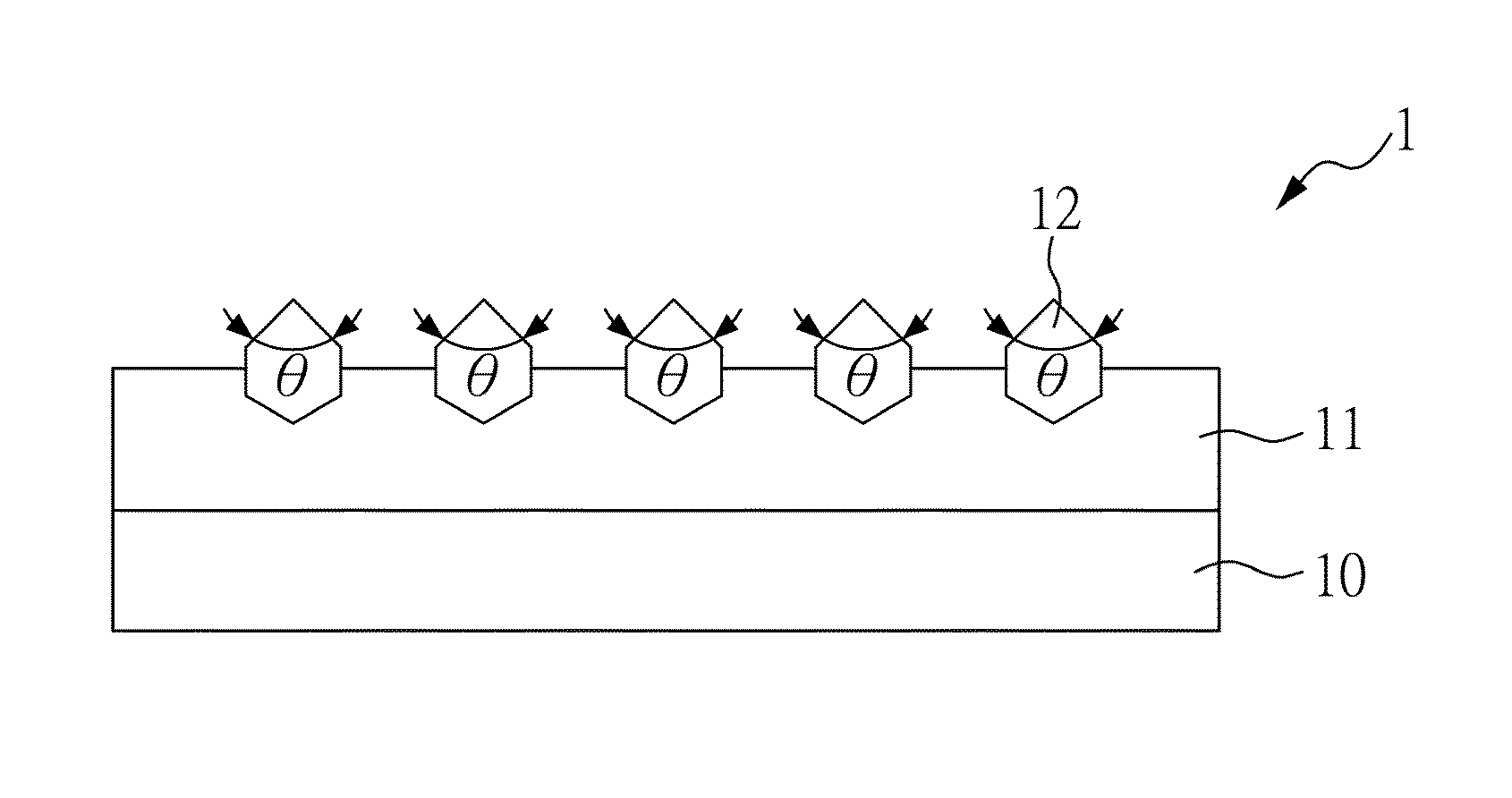

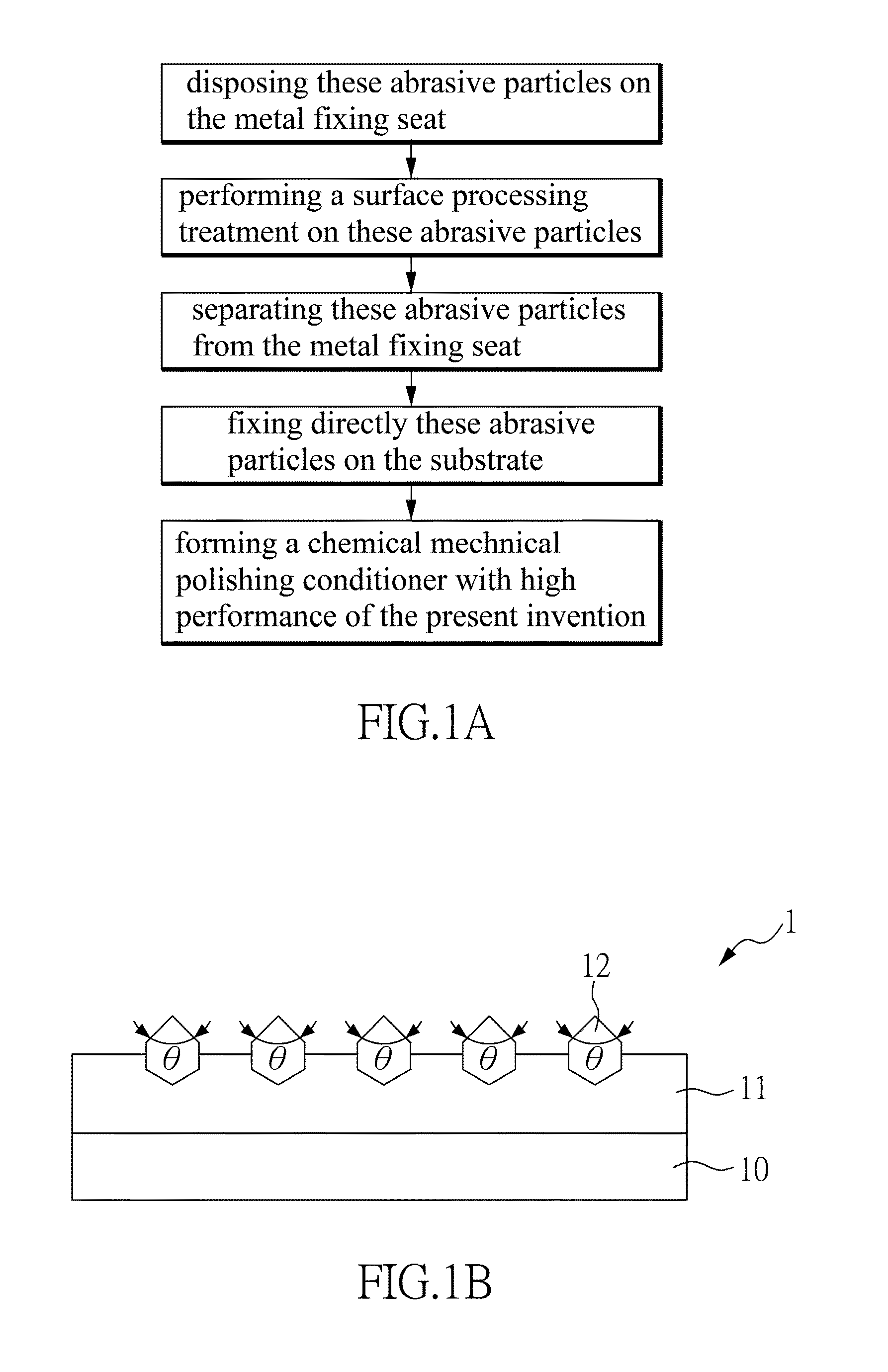

[0029]Please refer to FIGS. 1A and 1B, FIG. 1A shows a block flow diagram of a chemical mechanical polishing conditioner with high performance of the present invention, and FIG. 1B shows a schematic diagram of a chemical mechanical polishing conditioner with high performance of the present invention. Please refer to FIGS. 1A and 1B, in the chemical mechanical polishing conditioner with high performance according to Example 1 of the present invention, first, these abrasive particles 12 are disposed on a metal fixing seat (not shown); wherein the these abrasive particles 12 are artificial diamonds with particle size of 300 μm. Secondly, these abrasive particles 12 are performed a surface processing treatment, so that these abrasive particles have specific cutting edge angle (θ) of 90 degree. Please refer to FIG. 1B, theses abrasive particles can avoid limitations of theirs crystal forms based on a condition of figure of a single abrasive particle to obtain an optimum cutting edge angl...

example 2

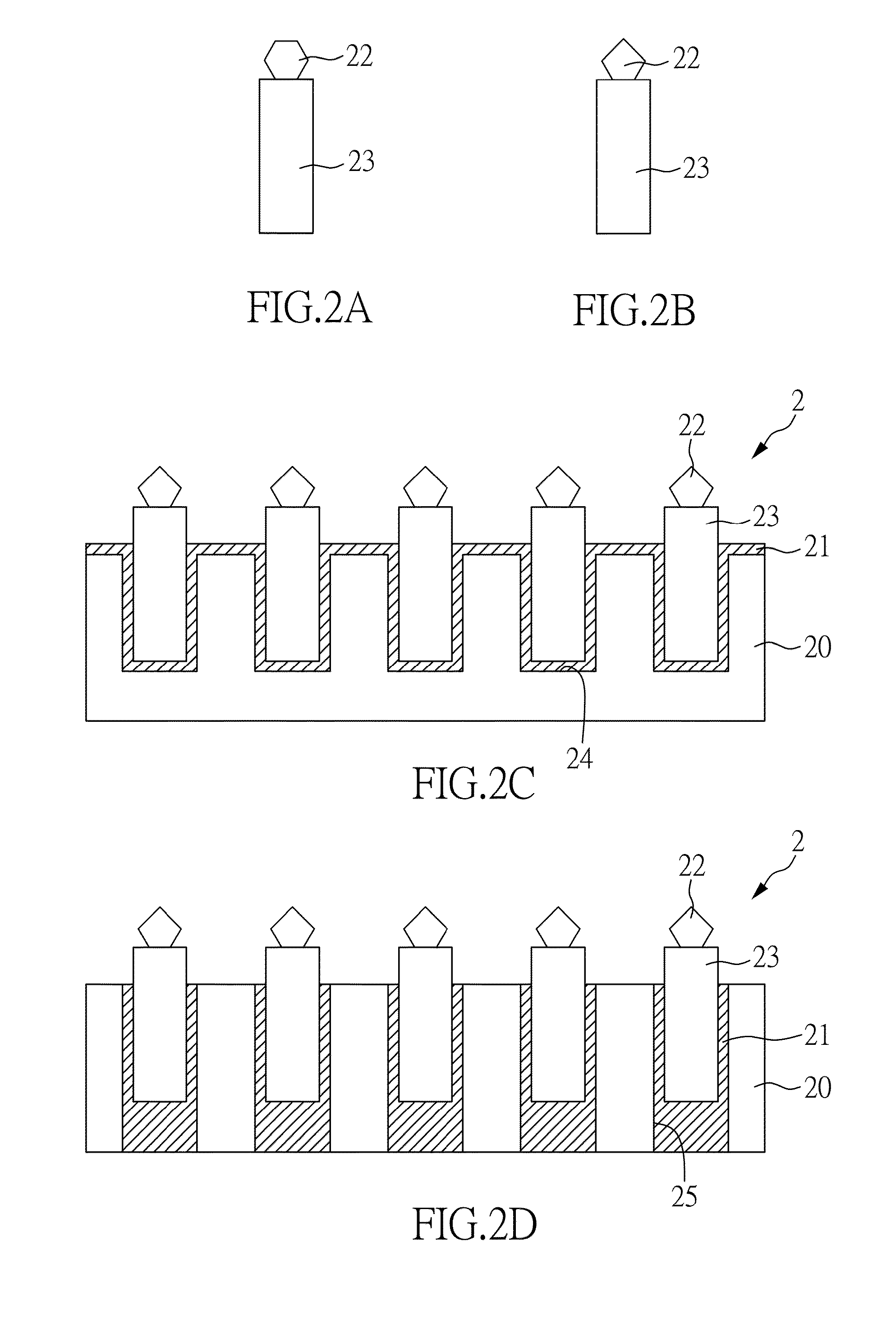

[0030]Please refer to FIG. 2, FIG. 2 shows schematic diagrams of the chemical mechanical polishing conditioner with high performance according to Example 2 of the present invention. The device of the chemical mechanical polishing conditioner 20 with high performance of Example 2 is substantially the same as the above Example 1, but the differences are that the abrasive particles 12 of Example 1 are fixed directly on the substrate by the binding layer 11, and the abrasive particles 22 of Example 2 are disposed on the metal fixing seat 23. Please refer to FIG. 2A, each abrasive particle 22 is disposed on the metal fixing seat 23 having plane top; wherein these abrasive particles 22 are artificial diamonds with particle size of 800 μm. Besides, the metal fixing seat 23 having the plane top is a cylinder figure of which the external diameter is 3 mm and each abrasive particle 22 is fixed on the metal fixing seat 23 having plane top by the abrasive binding layer (not shown in figures) ma...

example 3

[0031]Please refer to FIGS. 3A to 3C, FIGS. 3A to 3C show schematic diagrams of the chemical mechanical polishing conditioner with high performance according to Example 3 of the present invention. The device of the chemical mechanical polishing conditioner with high performance of Example 3 is substantially the same as the above Example 2, but the differences are that these abrasive particles having plane bottoms are disposed on the metal fixing seat with plane tops in Example 2, but these abrasive particles having non-plane bottoms are disposed on the metal fixing seat with blind holes at top, so that these abrasive particles having non-plane bottoms are corresponded to the metal fixing seat with blind holes at top. Please refer to FIG. 3A, first, theses abrasive particles 32 having non-plane bottoms are disposed on the metal fixing seat 33 with blind holes at top; wherein theses abrasive particles 32 are artificial diamonds with particle size of 800 μm, and the metal fixing seats ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com