Compositions in the Form of Dissolvable Solid Structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

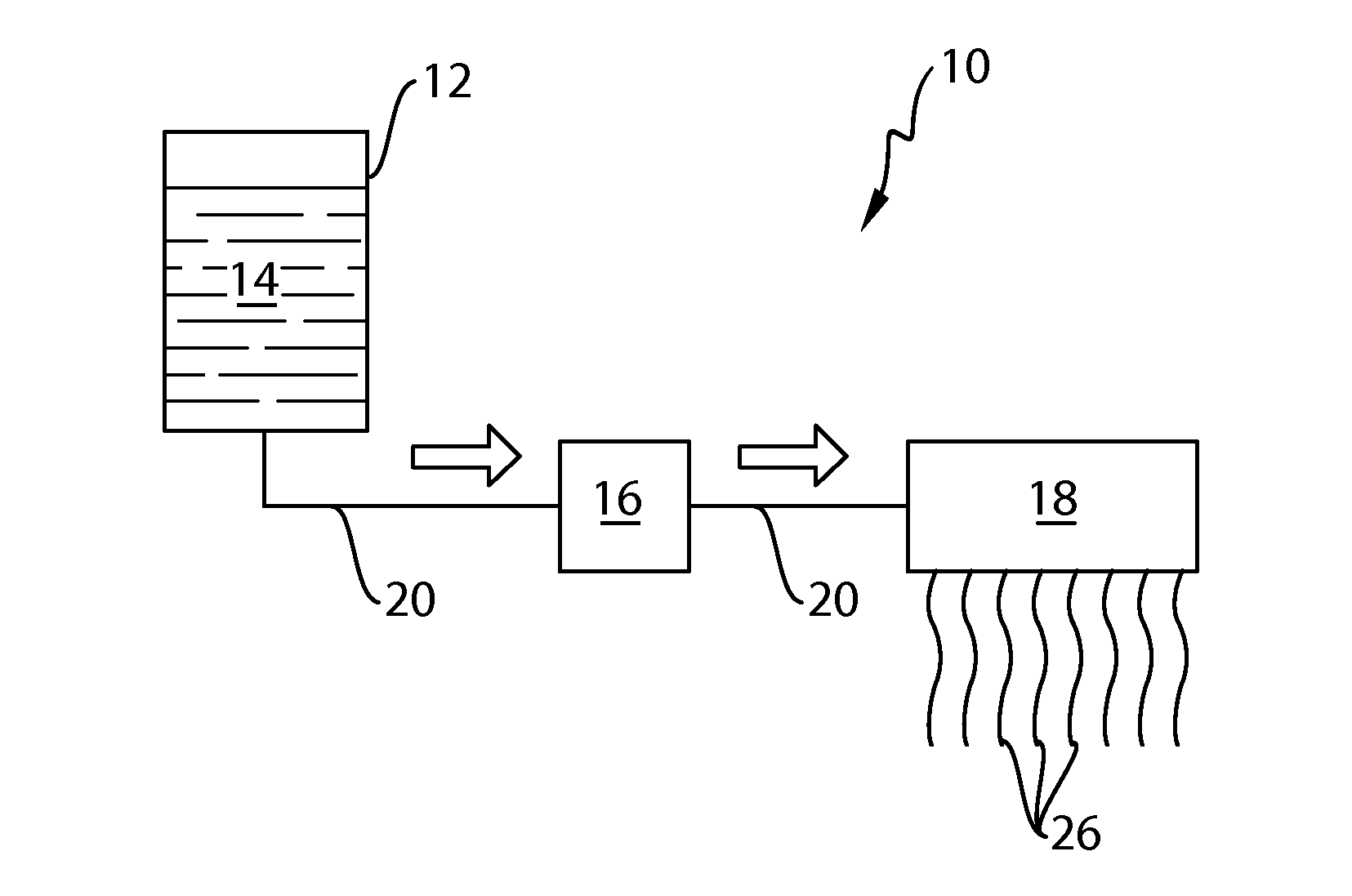

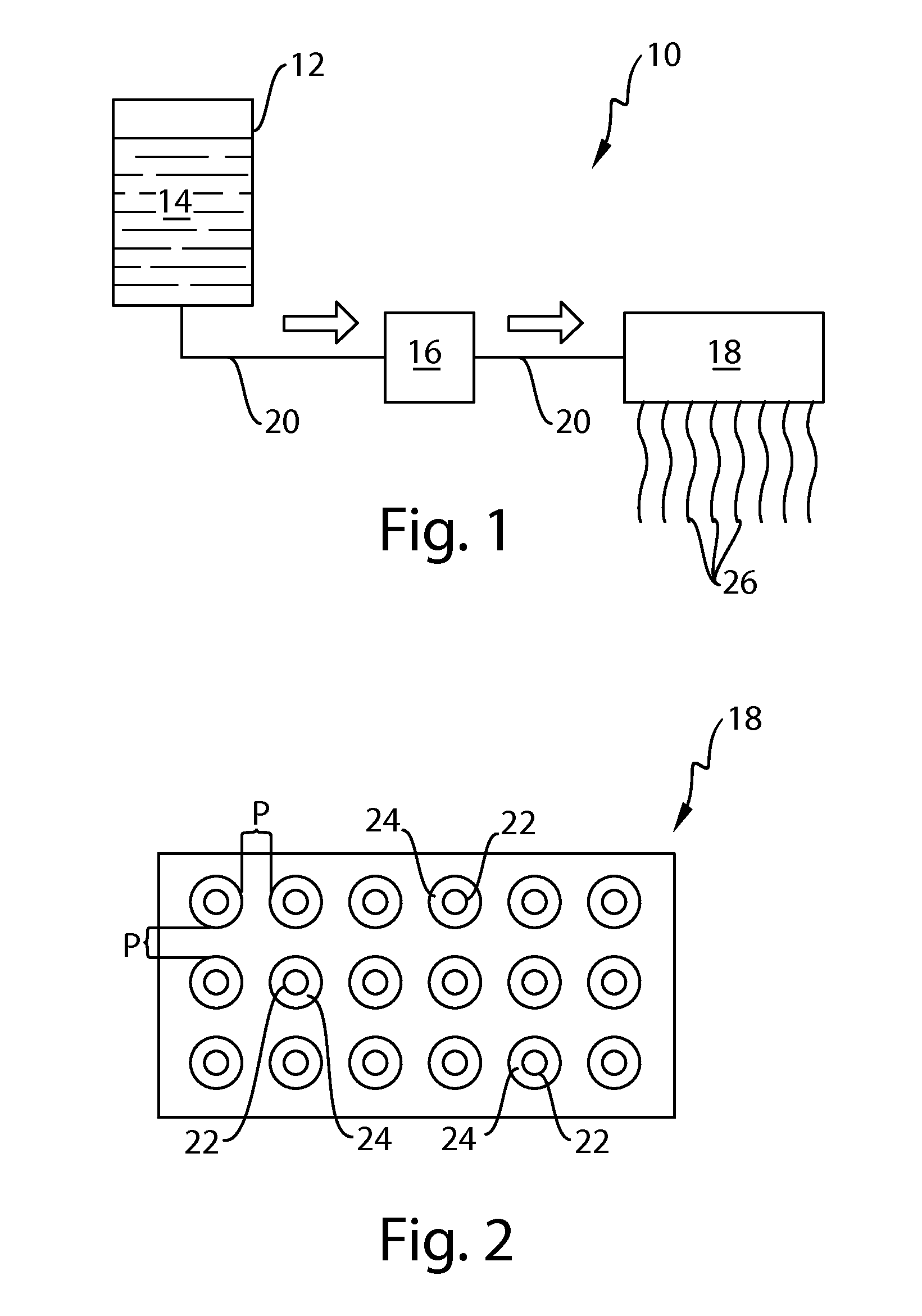

Method used

Image

Examples

example 1

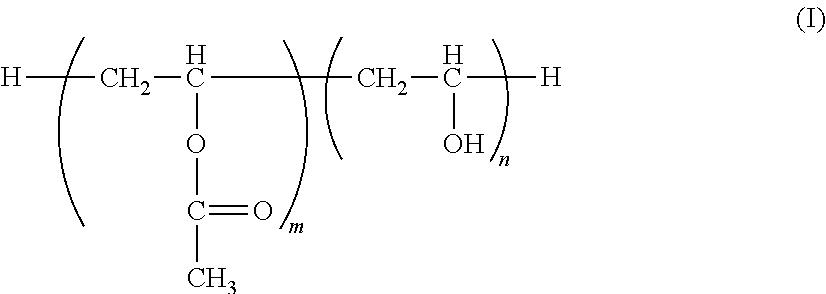

Dissolvable Porous Solid Cleanser (Fibrous Structure) with Low Hydrolysis Vinyl Acetate-Vinyl Alcohol Copolymer

[0184]Table 1 below sets forth a non-limiting example of a premix (a fiber-forming composition) of the present invention for making fibers and / or a fibrous structure (nonwoven web) of the present invention via the fibrous structure making process described immediately above. The fibrous Structure is suitable for providing a beauty benefit, for example suitable for use as a shampoo.

TABLE 1% by weight offiber-formingcompositionMaterial(i.e., premix)Low Molecular Weight, Low hydrolysis vinyl5.13acetate-vinyl alcohol copolymer1High Molecular Weight, Low hydrolysis vinyl5.13acetate-vinyl alcohol copolymer2Lauryl Hydroxysultaine (40.5% activity)15.4Sodium Laureth-1 Sulfate (70% activity)29.9Cationic cellulose (cationic polymer)30.5Citric Acid0.4Distilled water43.541PVA403, Mw 30,000, 78-82% hydrolyzed, available from Kuraray America, Inc.2PVA420H, Mw 75,000, 78-82% hydrolyzed, av...

examples 2 and 3

Dissolvable Porous Solid Cleanser (Open Cell Foam) with Low Hydrolysis Vinyl Acetate-Vinyl Alcohol Copolymer

[0191]Table 3 below sets forth non-limiting examples of premixes for making an open celled foam Structure of the present invention. The premixes are formed using relatively low water (c. 60 wt %) / high solids (c. 40%) solids content. The foam Structure is suitable for providing a beauty benefit, for example suitable for use as a shampoo.

TABLE 3Example 2Example 3ComponentWt %Wt %Distilled waterqsqsGlycerin3.83.8Polyvinyl alcohol 420H19.56Polyvinyl alcohol 2052—3.5Sodium Laureth-3 sulfate1.81.8Sodium Laureth-1 sulfate12.912.9Sodium Lauryl Amphoacetate9.69.6Guar Hydroxypropyltrimonium0.50.5Chloride3Citric Acid1.81.8Total1001001PVA420H, Mw 75,000, 78-82% hydrolyzed, available from Kuraray America, Inc.2PVA 205, MW 39,000, 87-89% hydrolyzed, available from Sekisui Specialty Chemicals3Jaguar ® C500 supplied by Solvay-RhodiaNote that the wt % value for the Sodium Laureth-3 sulfate, So...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com